Guide to Unusual 3D Printing Materials

Posted By Romain Cabanis on Apr 15, 2015 | 0 comments

If you’re interested in 3D printing and our manufacturing methods, you probably know about the most widely used 3D printing materials. Those include polyamide, resin, alumide, multicolor and some metals. However, these materials are just the tip of the iceburg, 3D printing has many other hidden surprises.

The following guide will help you learn more about the materials and manufacturing methods that are not found in conventional 3D printing. We’ll display the most amazing materials used in 3D printing, their functions and their technical achievement and printing. We divide these unusual materials into 5 categories:

- Building Construction

- Augmented Reality

- Artistic

- Human Body Experience

- Edibles

Each material has its own particularity when it comes to its technical specifications. However, if you’re not interested in strength, weight, tightness, heat resistance, or the cost of production, the aesthetic quality is almost always intriguing. The term “3D printing” is often vague in its definition because it describes a wide range of manufacturing processes. One thing we can agree on is 3D printing takes a 3D file and turns it into a 3D object – how exactly it gets there is often wild and sometimes whacky.

Building Construction

This category includes some unusual materials are mainly used for construction. Realization can range from simple everyday object to an entire building.

Cement

Field of Use: Construction of exterior walls

Resistance/Solidity: Excellent

Printing Method: Cement deposit with huge 3D printers that can measure up to 50 meters in length. Smaller structures can be constructed with a ‘WASP’ 3D printer

Field of Use: Sculpture and Construction

Resistance/Solidity: High heat resistance, porous

Printing Method: Malleable clay deposit, cooled and then solidified by fans. Clay can be printed through the Delta WASP or the HyRel.

Augmented Reality

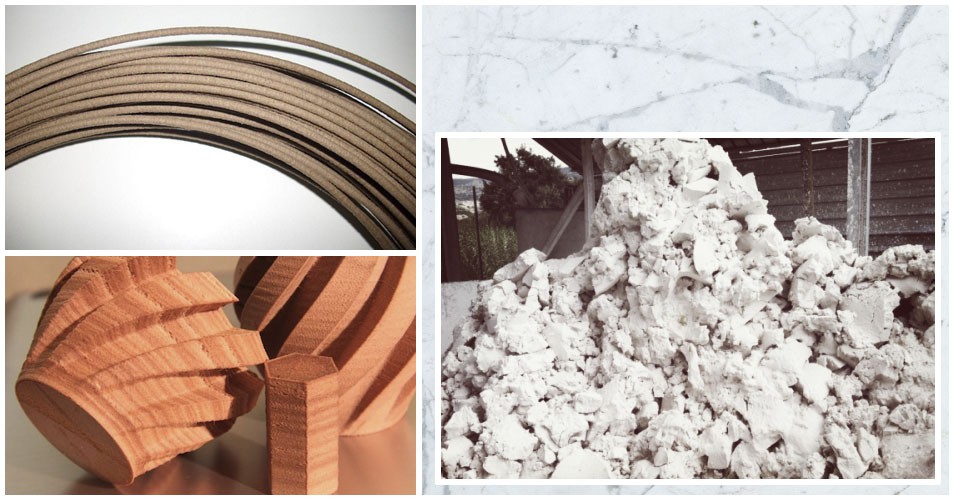

This category combines the unusual materials that mimic other, more common materials like wood or marble. These materials are not marble nor wood, however – they are a blend of materials that offer similar material qualities to offer an aesthetic similarity. These materials could not be substituted for their traditional counterparts (yet).

Field of Use: Creating objects that imitate wood

Resistance/Solidity: Shockproof, should be kept away from moisture and combustion.

Printing Method: Similar to FDM printing, the “Laywoo-3D” wood filament is coiled and extruded onto a heated base where the object is created upward layer by layer. The RepRap 3D printer is compatible with this material.

Field of Use: Architecture, creating objects that look like rock

Resistance/Solidity: Overall solid resistance

Printing Method: Rock filament deposition, also known as “Laybrick” (similar to Laywood), compatible with RepRap printers.

Marble

Field of Use: Marble ImitationImitation du marbre

Resistance/Solidity: Excellent

Printing Method: MarbleEcoDesign, a precursor to FFF marble printers (which are currently out of production), marble is printed using classic 3D printing techniques.

Artistic

This category refers some unusual materials that are more artistic in nature, but can also hold their own in technical fields. These are relatively unclassifiable materials, a phenomenon that is due to their high versatility and the uncertainty of their true and final potential.

Field of Use: Art

Resistance/Solidity: Weak

Printing Method: Wax sculptures are printed with natural wax which is passed through a silicon mold and left to harden.

Field of Use: Sand Sculpture, Mold creation

Resistance/Solidity: Solid resistance, to be kept away from moisture

Printing Method: The 5-Max sand printer uses conventional 3D printing methods. SolarSinter however, manages to create sand structures using only solar energy, a 100% eco-friendly process.

Paper

Field of Use: Sculptural and Renditions

Resistance/Solidity: Very low resistance, the paper is easily altered by water

Printing Method: Printing by the lamination of consecutive layers of paper

Glass

Field of Use: Sculpture

Resistance/Solidity: Very good resistance, fragile to violent shocks

Printing Method: Eco-friendly material, glass 3D printing to the point where we are now, is carried out by conventional 3D printing means.

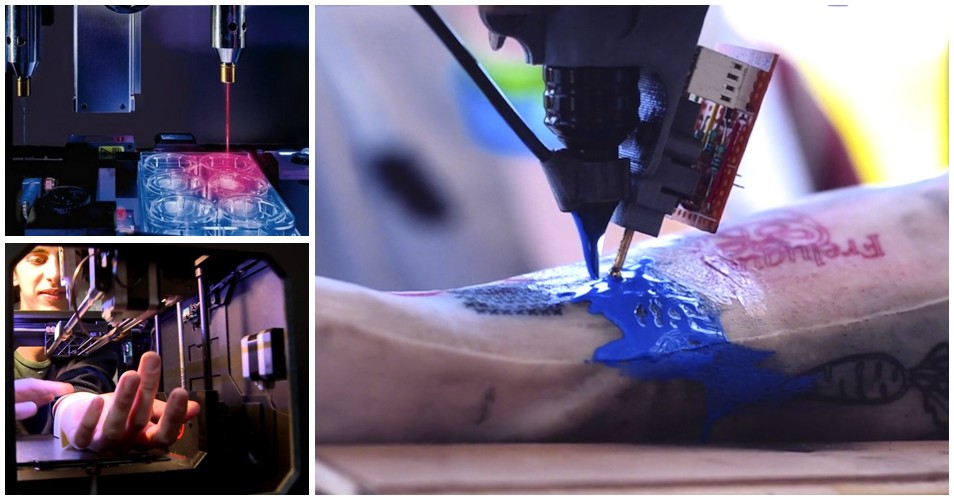

Human Body Experience

This category proves that 3D printing is revolutionizing the art and science. You will see that there will soon be no doubt that soon we will have 3D printing (directly) in the skin.

Field of Use: Medecine, Science Biology

Printing Method: Transplantation and cultivation of organic cells in a gel base. These cells are constantly supplied with blood. The same method is used in FDM printing.

Field of Use: Tattooing

Printing Method: A mechanical arm with a needle injects the ink directly below the epidermis

Just-to-Eat Category

3D printing not only inspires our imagination, it also inspires our appetites! Some new printers are able to recreate any sort of edible form candy to food. It is also very likely that within a few years, 3D printed food will be on the front lines for soldiers.

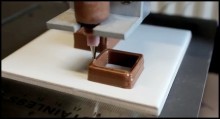

Chocolate

Field of Use: Culinary

Printing Method: Chocolate 3D printing is done in the same manner as FDM printing in which a melted material is deposited layer by layer to form an object

Food

Field of Use: Culinary

Printing Method: Programmable recipes are available on the 3D printer’s interface. Available Foodini food capsules are selected then printed through layer deposition. The food can then be cooked in a microwave oven.

Field of Use: Culinary, Artistic

Printing Method: Deposition of an aromatic resin using traditional FDM printing techniques.

If you’re interested in more updates like this be sure to follow us on Twitter and Facebook!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook