Material can change shape with 4D Printing

Posted By Sculpteo on Jul 22, 2015 | 0 comments

3D Printing is already reshaping a large number of industries and no-doubt that all potential applications are not discovered yet. This doesn’t prevent the researchers to work on the next step: 4D Printing. Programmable materials are able to change shape without complex stimulation. Watch them in action.

4D Printing is developed by Self-assembly Lab, which is a cross-disciplinary research lab at MIT inventing self-assembly and programmable material technologies aimed at reimagining construction, manufacturing, product assembly and performance.

4D Printing project is a part of their Programmable Material field of research. They describe it as “the science, engineering and design of physical matter that has the ability to change form and/or function in a programmable manner. 4D Printing, where the 4th dimension is time, is one recent example of PM that allows objects to be printed and self-transform in shape and material property when subjected to energy.”

Just like 3D Printing, 4D Printing work as a combination between Software + Material + Printer. MIT Self-Assembly Lab collaborates with Stratasys and Autodesk to work out this new process for printing customizable smart materials. 4D Printing entails multi-material prints utilizing the Stratasys Connex printer with the added capability of shape-transformation from one state to another, directly off the print-bed. This technique offers a streamlined path from idea to full functionality built directly into the materials, including; actuation, sensing and material logic. Potential applications include; robotics-like behavior without the reliance on complex electro-mechanical devices as well as adaptive products, garments or mechanisms that respond to user-demands and fluctuating environments.

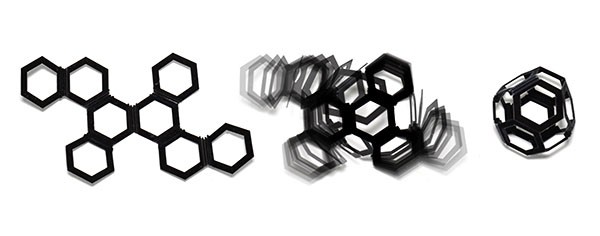

With a single multi-material print, a product or mechanism can transform from any 1D strand into 3D shape, 2D surface into 3D shape or morph from one 3D shape into another. Using only water, heat, light or other simple energy input, this technique offers adaptability and dynamic response for structures and systems of all sizes. Pictures are worth a thousand words in this case, so we invite you to watch these videos and judge for yourself.

4D Printing: Doubly Curved Surface from Self-Assembly Lab, MIT on Vimeo.

4D Printing: Surface to Sine Wave from Self-Assembly Lab, MIT on Vimeo.

4D Printing: Truncated Octahedron from Self-Assembly Lab, MIT on Vimeo.

4D Printing: Self-Folding Protein from Self-Assembly Lab, MIT on Vimeo.

The industrialisation timeline for this new technique has not been disclosed yet. Before the start of the 4D Printing era, it would be good to hurry on 3D Printing! Check out our 3D printing material pages to imagine what is already possible today. You can also download our free ebooks to discover 3D printing applications:

Don’t hesitate to contact our support team if you need advice on 3D printing materials and your project.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook