3D printed batteries to go further, faster and cleaner!

Posted By Antu Nehuen on Sep 1, 2015 | 0 comments

Batteries. We use them everywhere and all the time to the point of having become seriously dependent on them. That is exactly why it may come as a surprise how in this current era of constant innovation meant to make our lives easier there is that one single component embedded on most of ours daily used gadgets that has barely changed in the last 40 years since its conception.

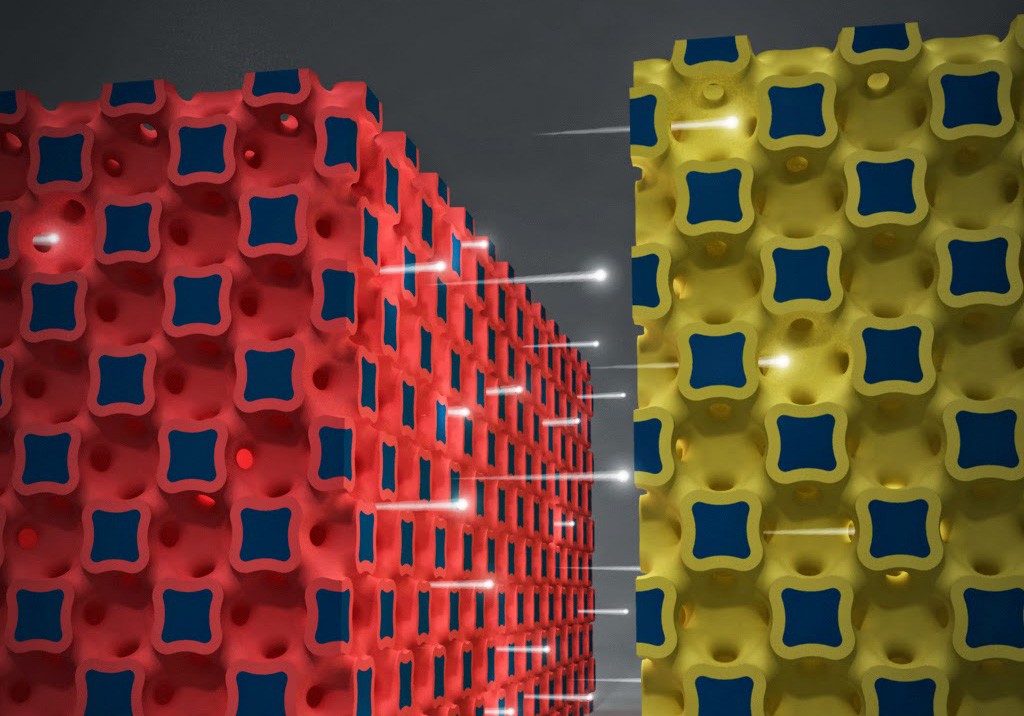

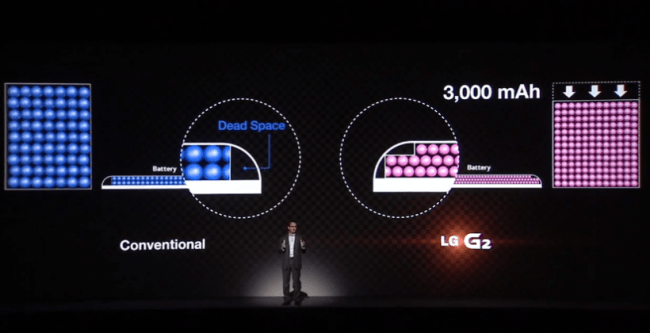

Clearly, we are talking about batteries and the good news is that this situation may be about to change for the better thanks to several teams of scientist at Manchester Metropolitan University in the UK, the Ulsan National Institute of Science in Korea and Harvard University in the US, all of them of them after efficient and energy dense 3D-printed battery prototypes. Although working with different materials, all these research groups have decided to take advantage of the flexibility offered by 3D printing technologies to create complex inner structures that enhance the battery’s internal chemical reactions allowing them to increase its capacity in some cases or allow them to reshape the entire body of the battery to perfectly fit the device that it will power, as some manufacturers are already starting to do in a simplified way, using more traditional battery production techniques.

In the race for the slimmest device, several manufacturers are adopting complicated production processes to gain just a bit extra juice out of their batteries.

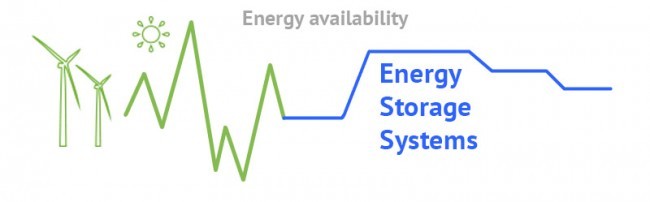

But all this progress goes way beyond just boosting your smartphone’s battery, as there are also decisive challenges to overcome in the near future. We are living in an energy-thirsty world that is gradually shifting toward sustainable ways to produce all the energy that runs everything around us, and often those renewable sources offer a great deal of energy but not steadily, like a dirty old fashion coal power plant would do. This means that we are in need of newer, cheaper alternatives to store the extra energy that may be produced by, for example, a solar power plant during the day to be used afterwards.

To tackle this demand and going one step further than everyone else, the team from Manchester Metropolitan University has been funded with a £500,000 grant from the national Engineering and Physical Sciences Research Council to develop a new kind of energy storage system (ESS) using a conductive graphene ink and a desktop printer capable to print these ESS. This outstanding material and its unique properties, among them its high electrical and thermal conductivity, outperforms the graphite commonly used in most Lithium-ion batteries today but not without its technical challenges. Professor Craig Banks explains:

“In addition to the choice of material, the overall architecture of ESS are of critical importance. The architecture of ESS can be improved through the use of 3D structures, which have high surface areas, good electrical properties and hierarchical pore structures/porous channels. We’re trying to achieve a conductive ink that blends the fantastic properties of graphene with the ease of use of 3D printing to be manipulated into a structure that’s beneficial for batteries and supercapacitors.”

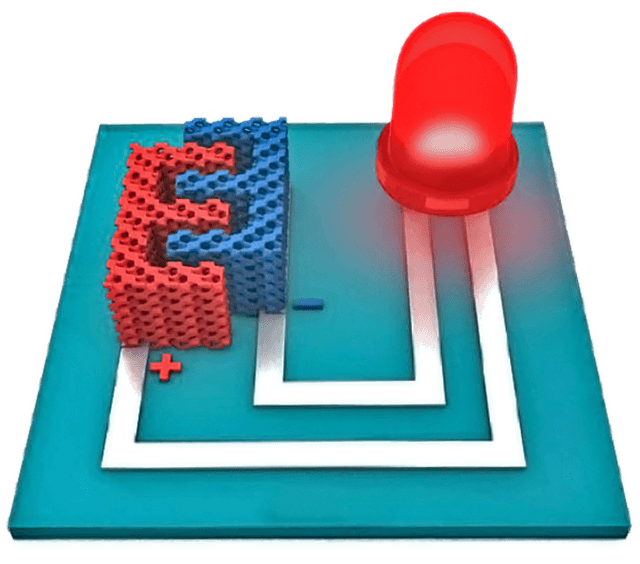

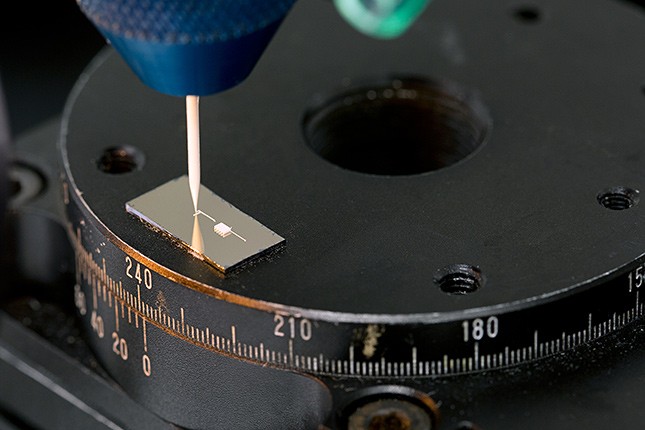

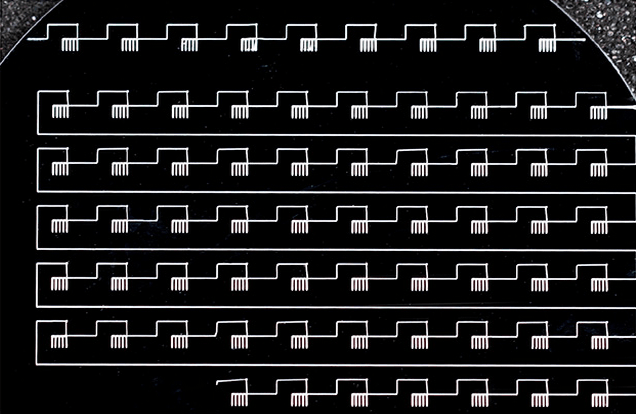

With a different approach and objective, the team from Harvard University lead by materials scientist Jennifer Lewis is also making use of 3D printing to develop lithium-ion batteries, just like the ones inside our phones and laptops, but at a whole different scale, at a fraction of a millimeter in size ( 0.2mm – 0.008” ). These micro batteries came to life by accurately printing stacks of different compounds’ layers (Li4Ti5O12 or LTO and LiFePO4 or LFP) , serving as the anode and the cathode respectively and could enable the development of self powered miniaturized electronics, robots, medical implants and more.

Just like FDM printing, but tinier! Credits: technologyreview.com

They may be small but they are also completely scalable if higher capacity was necessary.

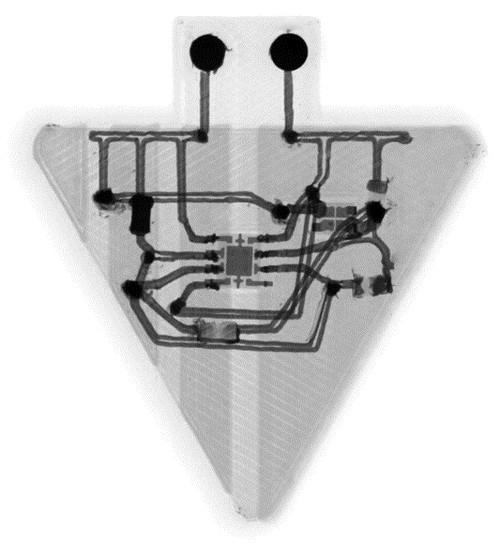

Simultaneously on the other side of the world, another team is forthcoming wearable electronic devices that may not be extremely small but will need to offer other characteristics like flexibility or complex customized shapes. Researchers at the Ulsan Institute of Science and Technology in South Korea have developed a novel production technique of Lithium-Ion batteries that gets us one step closer to direct electronics printing. In recent years more and more electronic components have become 3D-printable and it is not too far-fetched that in a not so distant future we are going to be prototyping smart functional hi-tech devices right at home. It seems like the future of 3D printing is bound to get increasingly amazing and sophisticated.

Credits: voxel8.co

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook