Are ALL 3D Printed Materials Toxic?

Posted By Jess Hedstrom on Nov 25, 2015 | 0 comments

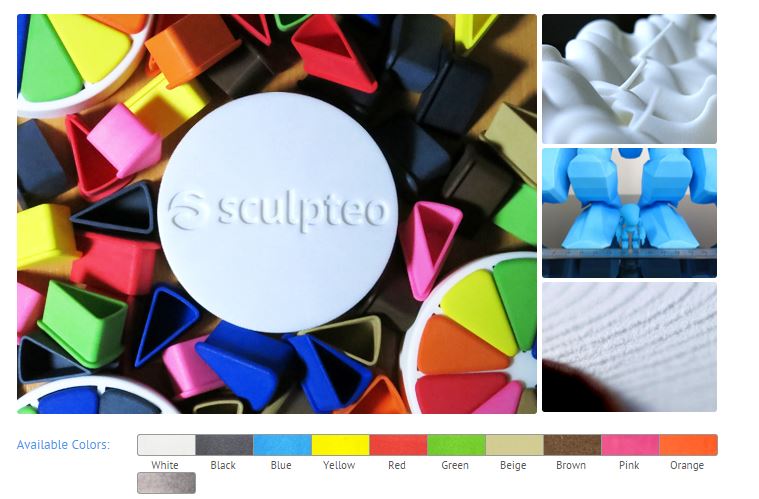

How safe are 3D printed materials? Recently we’ve seen studies that suggest some materials may be harmful; we’re here to tell you about our Sculpteo materials so that you (and your customers) can put your fears to rest.

We’re going to start with the basics, this article will give you a better understanding of the materials that we use to create your products, and while all of this information is available on our materials page we feel that walking you through each material and talking about their chemical compounds will be much easier for you. We have to preface by saying, this information is specific to Sculpteo’s 3D printers and while this info might be applicable to other commercial 3D printers we can only speak on behalf of the materials we use in our printers.

In order to determine toxicity of each 3D printed material we’re categorizing the safety of the materials against these 3 areas. Are these materials safe to handle, are they safe to eat or drink from, and finally are they safe for the environment.

Is the 3D printed plastic powder from SLS printers safe?

Plastic is one of the most popular materials used in manufacturing (additive and otherwise), it’s used for a wide range of items, including some items that might surprise you. SLS technology and 3D printing is new to the general public however the use of plastics in everyday items is not new; I’m happy to share with you that the plastic that we use at Sculpteo is completely safe!

Safe to Handle

The 3D printed plastic powder that we use is completely safe to handle! You do not need to be concerned when choosing to create objects such as (but not limited to) enclosures, jewelry, and toys from our plastic material. The nylon based plastic powder that we use to sinter your objects was engineered with the end consumer in mind, knowing that the objects will be handled by adults, children and the elderly the powder is non-hazardous and non-toxic for contact with human tissue.

*Our plastic nylon material is not flame retardant so make sure to keep your objects away from open flames.

Consumption

Obviously you do not want to eat an object made from with our SLS nylon plastic powder, just as you would not want to eat a plastic object created using injection molding technology. With that being said you can certainly use our plastic powder to create objects such as cups, plates, and items like whistles… etc.

Our plastic nylon blend was engineered with FDA regulations in mind, and it also passes the European REACH agreements, these are the governmental agencies and agreements that regulate food safety. Have peace of mind knowing that the plastic material offered by Sculpteo will be safe for you and your consumers.

The Environment

Our plastic nylon blend can be recycled; the loose powder that we do not use to create your object (you can see it in the photo above) can be recycled to create future objects. Once an object is created such as the mug pictured above it cannot be reduced to plastic powder again; however the loose powder can be reused to create additional objects. There is very little material waste that results from SLS technology. Typically cutting fluids are the main source of hazardous materials in the manufacturing process, but because 3D printing is additive and not subtractive we are not required to cut away at the material to create your objects. There are no aerosol or liquid residues of any kind with this material.

Is the 3D printed Full Color Sandstone Material safe?

Full color sandstone is a great material for capturing a spectrum of colors in your prints, they are primarily used for figurines and and artistic prints. With a range of 390,000 colors available to you this is another popular material and 3D printing technology that a lot of our customers enjoy. Let’s take a deeper look at this material with our 3 categories in mind.

Safe to Handle

Much like our plastic nylon blend this material is also in powder form and completely safe to handle! Items printed in multicolor can withstand temperatures of up to 60°C (140°F) – beyond that the object’s properties can be significantly altered. Multicolor objects are also somewhat fragile (comparable to a porcelain), so it is important to handle them with caution, and because the prints have a gritty surface and are relatively porous, it is important to avoid direct contact with water as it could result in discoloration or running of the colors. This material is not hazardous for the end consumer, it’s flame retardant and non-carcinogenic.

Consumption

The full color sandstone material is not food safe. Although it is not carcinogenic, we do not recommend eating or drinking from items made in this material. As a result we do not recommend creating toys or items for children from this material just to be on the safe side.

The Environment

Full color sandstone is environmentally safe and like the plastic powder it can be recycled. There is very little material waste that results from this technology and once again because 3D printing is additive and not subtractive we are not required to cut away at the material to create your objects, which drastically reduces hazardous waste. There are no aerosol or liquid residues of any kind with this material, and because no support material is required in this process (also true with our plastic nylon material) there are no excess/useless parts to be tossed after processing.

Is the 3D printed Alumide material safe?

Objects printed in Alumide are made from a mix of polyamide powder and fine aluminum particles. The raw material makes for a matte surface which is somewhat porous and shiny. Alumide is no more or less durable than polyamide. In fact, their physical properties are very similar. This makes for great freedom in your designs – allowing for both complex and enclosed items. With regards to water qualities, Alumide is water-resistant but not waterproof. Thus the 3D object must not rest in contact with water for extended periods of time.

Safe to Handle

In terms of temperature, if the Alumide is subjected to heat above 120°C (248°F), it is possible that the physical form of the object can be significantly altered. As a result of their rough surface, objects in Alumide quickly become dirtied. This can often be remedied with soapy water and a cloth, letting it dry thoroughly. This material is typically used for tooling and can be handled with no side effects. Alumide is not hazardous for the end consumer, however it is not flame retardant and non-carcinogenic.

Consumption

The Alumide material is not food safe. Although it is not carcinogenic, we do not recommend eating or drinking from items made in this material.

The Environment

This form of manufacturing is preferred over traditional manufacturing techniques; in this case Alumide 3D printing eliminates metal/metallic scraps that have to be disposed of. There is very little material waste that results from this technology and once again because 3D printing is additive and not subtractive we are not required to cut away at the material to create your objects, which drastically reduces hazardous waste, as well as scrap metal. There are no aerosol or liquid residues of any kind with this material, and because no support material is required in this process there are no excess/useless parts to be tossed after processing.

Is Sculpteo’s 3D printed High Detail Resin material safe?

Our high detail resin material creates 3D printed objects from a base of photosensitive polymer liquid. That liquid is then solidified by UV light layer by layer to create a rigid and highly detailed prints which are comparable to injection molded plastics. The final product has a naturally smooth surface which can be polished further to create near full transparency.

Safe to Handle

Sculpteo’s high detail resin material is typically used for objects that require the highest level of detail, and as a result it is used by designers, architects and etc. It can be handled, however it should be handled with care, it is a brittle material and if dropped it can chip and/or shatter entirely. With regards to water qualities, resin is water-resistant but not waterproof. Thus the 3D objects must not be exposed to water for extended periods of time. Regarding temperature, if the plastic is subjected to heat above 50°C (122°F), it is possible that the physical form of the object can significantly altered. It is not flame retardant and should be treated with care.

Consumption

You never want to ingest this material, or use this material for items that will be used to assist in the eating or drinking process. As a result we do not recommend creating toys or items for children from this material.

The Environment

The liquid photopolymer is cured with a UV light layer by layer to create your object, in it’s liquid form the resin is carcinogenic and should not be handled without the proper safety gear; however to the end user this is not an issue. Supports are used in the 3D printing process and liquid cannot be recycled so there is some waste incurred with this material; Sculpteo adheres to the Environmental Protection Agency (EPA) regulations regarding disposal.

Is Sculpteo’s 3D printed Silver material safe?

Sculpteo’s silver material is composed of 92.5% sterling silver and 7.5% metal alloy. The final product is solid but susceptible to scratching and wear as would a sterling silver product purchased from a mass producing jewelry store.

Safe to Handle

As I’m sure you’re aware Silver is not hazardous for the end consumer, it’s flame retardant and non-carcinogenic. This is a completely safe material to handle for Adults, children and the elderly.

Consumption

As with any metal you do not want to consume the material however you can make objects that assist with eating and drinking. Custom kitchen utensils are perfectly safe in this material.

The Environment

The process of creating your objects with our Silver material is a little different than our other materials, because we use a lost wax process your items are first 3D Printed in wax and a cast mold is formed, the wax is melted and liquid Silver is poured into the cast mold. From there it’s cooled and polished. The process is safe for the environment, although, there is a higher amount of waste compared to our other manufacturing techniques. This is a common technique used in manufacturing metal objects with 3D printing technology.

For more information regarding the 3D printing processes or design guidelines you can find information on our website. For the datasheets for each of these materials click within the material and scroll down to the bottom, there is a link available with a more in depth analysis of each material listed here. For any specific questions regarding materials you can reach out to us at [email protected]

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook