7 things that Medical 3D printing can already do

Posted By Claire Chabaud on Mar 30, 2016 | 0 comments

Medicine is a leading sector for innovative uses of 3D printing. The term “Medical 3D printing” refers to these innovations as an emerging area of technology that explores how 3D printing can be used to replace or support an existing biological structure. However between a bionic 3D printed human and the reality we are not there yet. So, what is actually possible to 3D print in Medicine today?

1. Medical equipment in inaccessible areas

Difficult to access areas are a real challenge for Medicine. How to convey the right amount of equipment? How to adapt your surgery to the unique case of your patient when you are limited in your tools? How to spread some simple medical knowledge by teaching to the local population how to treat recurring injuries and give them the tools to perform?

These problematics are determined by the fact that any medical surgery needs a lot of materialized tools to work. 3D printers are an interesting lead to solve these mains issues in inaccessible areas. The printers help to dematerialise numerous tools and avoid stocks. Meaning, whether you need a specific surgeon tool to hold an arm during an operation or you need many copies of one part, you can get them in less than a day with your 3D printer.

Of course, the path to make this solution viable is filled with obstacles, but not impossible. At least, it’s what the “Not Impossible” foundation wants to accomplish with actions as Project Daniel. Daniel is a Sudanese boy, who lost his arms during a bombing of his village in Nuba Mountains. Mick Ebeling, co-founder of the foundation traveled to meet him and 3D print him a prosthetic arm while teaching the local how to make it. In the end, with the democratization of personal 3D printers, it could be an effective and inexpensive way to help secluded population

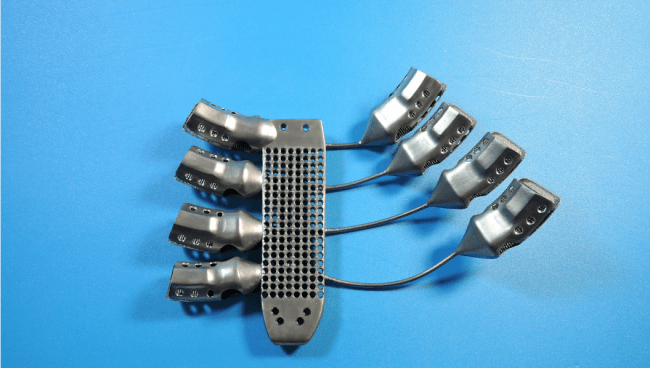

2. Create fully customized medical tools

In surgery, all operations need to be prepared and adapted to the particular case of a patient. Thus, Surgeons might need customized medical tools. But these ones take times to be manufactured and are costly to create with traditional means of production. Two issues very sensitives for this field, as they reduce the surgeon leeway in his operation in terms of reactivity and affordability for the patient.

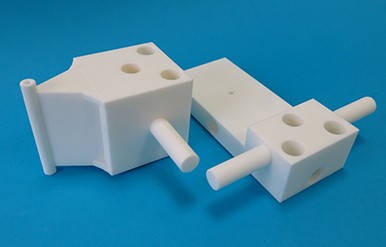

With the help of 3D modeling skills, surgeon tools are easily customizable in a 3D file, to be printed after. According to the fact that the doctor or hospital own a 3D printer or use a 3D printing service, tools can be prepared for the surgery in a day and are made to measure for the patient’s body.

Dr. Marc Soubeyrand quickly integrated this technology in his surgeries. He created Ancillary tools in Nylon on SLS 3D printers to give implants the best position during a surgery. The creation of made-to-measure tools, based on the medical data (scans, MRI, etc) of the patient, enables a very precise approach to the surgical practice.

3. Customized Drugs

Have you ever took 5-6 pills at the same time to care different health problems? Have you ever asked yourself if these different pills were effective when taken at the same time? Did you take pills that were inappropriate for your morphology? These questions are a real medical concern, as pre-determined dosage pills are made to cure anyone with standard medicine.

A disruptive solution has been found by a research group, led by Min Pu, MD, Professor of internal medicine in Wake Forest University to made tailored medications. His team elaborated an algorithm including information as weight, race, kidney and specific liver functions. This algorithm is embedded in a software that can create the personalized-dosage adjustment and turn it into 3D printable data. The test run by the team showed that the treatment based on this method could actually be more powerful than traditional medicine to cure the patients.

One drug, the Spirtam Levetiracetam is already 3D printed by the company Aprecia, which got an FDA approval in August 2015 by the U.S Food and Drug Administration. Today, we are not yet in the vision of Lee Cronin, in his TED talk were patients would go to an online drugstore with a digital prescription to buy the blueprint and chemical ink and then print their medications at home. To reach this point, many aspects should be approached by the law and the authorities to make this market safe for the patients and prevent them from potential harm made due to inadequate medicine. Still, the tailor-made drugs 3D printed by pharmaceutical groups are a reality closer than we think.

4. Medical education and training Surgical procedures with 3D printed models

Any surgical operation needs to be prepared before to be performed. Still, standard training equipment will not train the surgeon to the specificities of the patient’s body. Usually, this comprehensive knowledge is acquired by training on human cadavers in preclinical studies in medical school and gains in accuracy during real surgeries. At the moment, doctors are using 2D and 3D visualization on a computer to understand the anatomic details of their patients.

The possibility to create a 3D file based on an MRI or a scan, allows the surgeon to create real-case organs to practice their surgery. For example, to prepare an endovascular stent implantation simulating in vivo conditions and real tissues without any risk of patient complications, you can 3D print a heart in TPU 3D printed with SLS technology. It will give to the 3D model the flexibility required to be used in a training.

5. Find the best way to treat cancer

Tumors are very difficult to treat in Medicine because it’s difficult to know how they are going to react to the treatment. But what if, we can test the treatment ahead on patient’s tumor cells? It would help to avoid the iterative and exhausting phases of test for the patient and increase the efficiency and speed of the cure.

The institute for Regenerative Medicine of the Wake Forest university’s Baptist medical center is making a decisive step forward on its “metastasis-on-a-chip” system. The purpose of this system is to be laboratory models of cancer spreading from one 3D tissue to another. The idea is to test the patient tumors’ cells in this system and to test how to treat cancer according to the way cells spread.

3D printing is used to create the organoids to make all process more realistic. One of the main positive aspects of this innovation is that the system can overcome some lacks in the traditional methods. The university stated, “ For example, the results from traditional 2D studies in laboratory dishes, as well as studies in animals often, are not applicable to human patients.”

6 . Skin and tissues

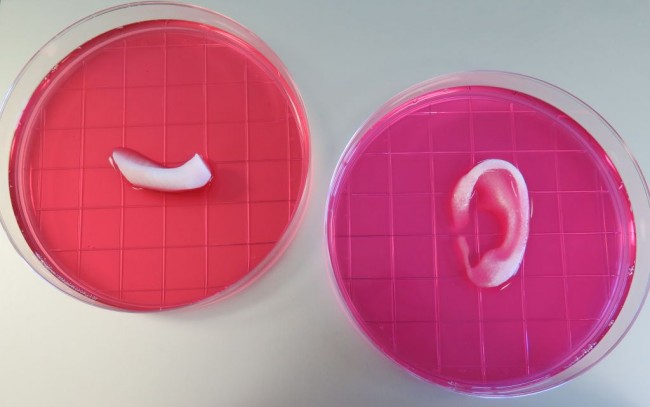

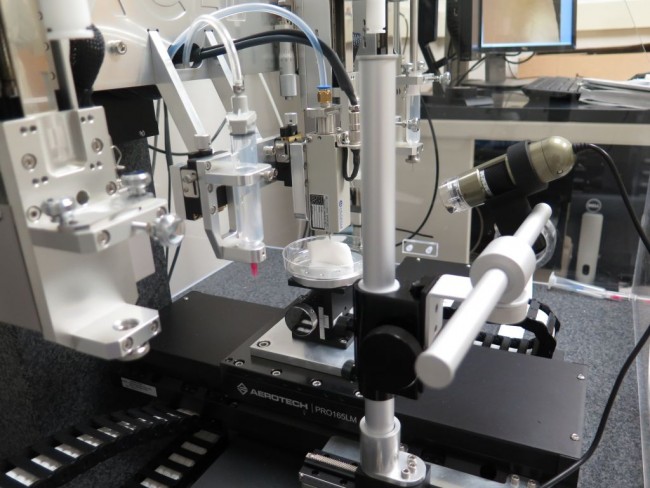

Bioprinting is mainly focused on the development of 3D printed skin and tissues. Currently, there are two main paths that are explored. The first one is the possibility to print skin directly on the body and the second one is to 3D print tissues that could actually be implemented in a human body.

For burnt patients, the skin reconstruction is a vital subject. The surgery takes a long time to be effective and succeed. Usually, a part of skins is removed from the body and placed on the burnt part. Still, depending on the injury importance, this technique might not be enough to cover the wound. Not only from a physical perspective, it is above all a problem for their health to prevent them from infection and fluid and heat loss.

At the Wake Forest School of Medicine, they are developing for a military purpose a 3D printer that can 3D print skin directly on burnt patients. The ink of the printer is made with different kinds of skin cells. If you want to discover how this printer works, you can have a look at the video on the university website.

The university is also making more extended research on 3D printing tissues, but not only for a military purpose. They used a standard 3D printer that put down layers of hydrogels, a water-based solutions containing human cells or others biodegradable materials. The 3D printed organ could actually be implanted to a person.

The innovation in 3D printing tissues, allow the research to go further in the 3D printing of organs, and more than an ear, bioprinting companies such as organovo, could in the future 3D print liver, heart or a kidney.

Apparently, bioprinted tissues might have already reached the market, as a start-up named BioBots unveiled a Human tissue 3D printer, the Biobot 1 at $10,000.

7. Prostheses

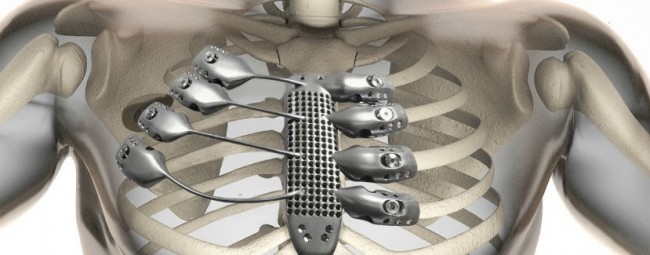

Because of their need for precise customization, Prostheses are one of the most advanced Medical-3D printing areas. Additive manufacturing has already been used in different cases; Mandible and Dental restoration, Hip replacement, Heart Valve , Hemi-knee joint reconstruction, Titanium ribcage, Skull reconstruction…

There are two categories of prostheses, external and internal. Internal prostheses are where 3D printing is the most used and disruptive. Usually, the main biocompatible materials used for this kind of surgery are metals, ceramics, and polymers. For example, in the case of a bone reconstruction, Bioceramics such as hydroxyapatite is used. Whereas to repair bone or cartilage, biodegradable polymer such as polycaprolactone is advised. Metals, as Titanium are more adapted to load-bearing areas such as hips.

Concerning External prostheses, 3D printing is making a breakthrough in terms of affordability and access. The charity e-Nable has created an Open-source model, the Raptor-Reloaded, to allow anyone with access to a 3D printer to print an internal prosthesis, at a low cost. The functions of this hand are still standard, but it’s full of promises for the future of this e-Nable and the democratization of external prostheses.

Presently, Medical 3D printing is improving medical solutions. Research departments are really active on this topic and we can expect a strong democratization of the use of this technology in Medicine. So if you want to discover more about how 3D printing will revolutionize the Medical industry, or what we could actually 3D print for the Healthcare industry have a look at our dedicated pages!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook