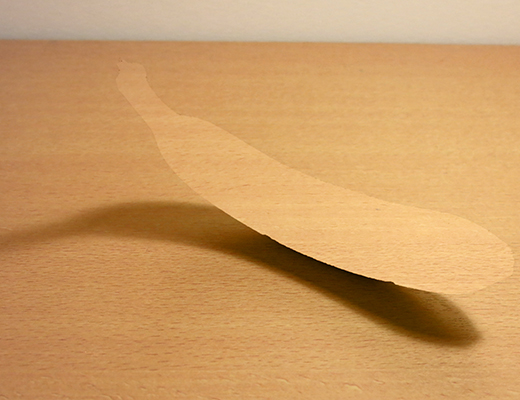

Sculpteo launches a new 3D printing offer with an invisible material!

Posted By Jess Hedstrom on Apr 1, 2016 | 0 comments

We are proud and excited to announce our new “Invisible Material”, and we probably know what you’re thinking…

Your imagination is the only limit to what you can do with Sculpteo’s new invisible material, so dream big!

In traditional SLS manufacturing your parts will be composed of thin layers which are almost invisible to the naked eye, unlike FDM. Our engineers have been working tirelessly in a room for months where the temperature rarely goes above 50°F, but finally they have emerged with the recipe for our invisible material. Our invisible material is the perfect material for all your needs, because it works for anyone and any industry! Aerospace, maritime, retail and more will be using invisible materials in the future, the applications are endless.

How does invisible materials for 3D printing work?

Much like traditional Selective Laser Sintering (SLS) manufacturing, our invisible material is built layer by layer, but what our engineers learned over the long cold winter months is that the powder used in the SLS process generates a thickness that can be reduced to some extent. The only limiting factor of this process is the size of the powder particle. So naturally we decided to remove the powder, and that’s where our breakthrough technology was born. ALS or Air Laser Sintering is the method used to create our invisible parts. If you’re interested in learning more about our new technology act fast it will only be available for 24 hours. April 1st, 2016 is the only day that you can learn more about this ALS technology and Sculpteo’s invisible material.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook