Aeronautics

GE Aviation, a General Electrics subsidiary specialised in jet engine production, relies on Additive Manufacturing to make jet fuel nozzle tips. The company announced in October 2018 that they 3D printed as much as 30 000 of these parts, as they made significant gains with this technology. With Additive Manufacturing, GE Aviation got to decrease the weight of the tips by 25%, and besides, to design an integrated assembly system which allowed to decrease the number of pieces within the part from 20.

Credit: General Electrics

Railway Industry

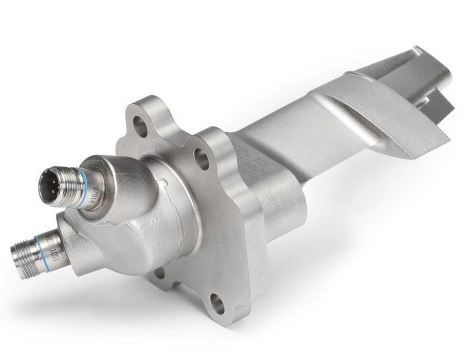

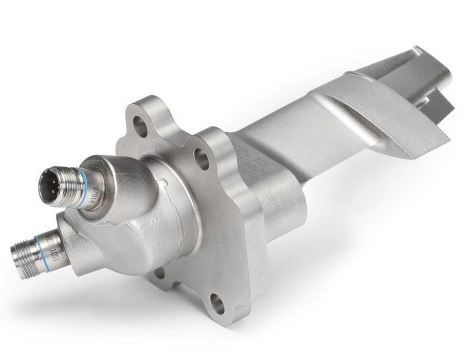

Transportations of all kinds can take advantage of the potential of 3D printed mechanics, and trains are no exception to the rule. German Mobility Goes Additive is a network seeking to foster the adoption of 3D Printing in various industries. They worked alongside Hamburg’s metro operator Hamburger Hochbahn AG to develop 3D printed safety-relevant and operational components for their vehicles. The project they achieved encompassed 3D printed mechanics such as brakes, and set a milestone for the use of Additive Manufacturing in the transport industry.

Credit: Mobility Goes Additive

Credit: Mobility Goes Additive

Automotive Industry

Car manufacturers have found many appeals in 3D Printing, and one of them certainly is spare-parts production. When it comes to old models especially, getting replacement parts for out of production vintage car turns tedious. To provide for this issue, Porsche’s old car division Porsche Classic is using Additive Manufacturing to get the spare parts needed to refurbish models. 3D printed mechanical parts such as the clutch release lever of the rare Porsche 959 have been achieved that way.

Electronics

3D Printing mechanics also has a number of applications in electronics. For Drone manufacturers, whose products integrate both mechanical and electronic systems, Additive Manufacturing appears to offer distinct benefits at development stages. For company UVify, which specialises in racing drones manufacturing, this technology has been used as a bedrock asset for prototyping. As the drones UVify is developing must present a good balance among performance, aerodynamics, and design, the company can go through tens of iterations. 3D Printing is in that sense a technology that UVify considers as key for their activity.

Aerospace

Spacecraft manufacturing is also a good example of how 3D Printing can be utilized to make, test and get functional parts time-efficiently. NASA and satellite launch service Virgin Orbit have collaborated on the creation of the first 3D printed rocket combustion chamber, which was successfully tested at NASA’s Marshall Space Flight Center. This project falls within NASA’s vision of harnessing 3D Printing to develop safer, more time-efficient and cost-effective launch devices.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook