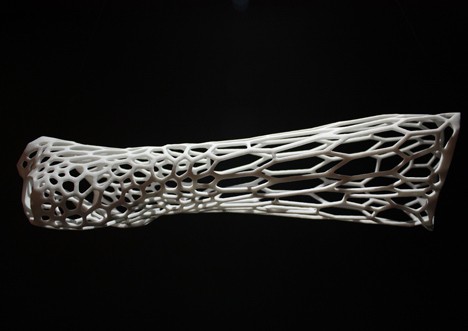

Industrial designer imagines a 3D printed cast.

Posted By Arthur Cassaignau on Jul 4, 2013 | 0 comments

Medical 3D printing has established itself as a big trend for the industry. We’ve seen different articles about life-saving devices or splints but it’s the first 3D-printed cast for fractured bones. The idea behind this project is to replace the usual bulky, itchy and smelly plaster.

“After many centuries of splints and cumbersome plaster casts that have been the itchy and smelly bane of millions of children, adults and the aged alike, the world over, we at last bring fracture support into the twenty-first century.” writes designer Jake Evill.

Jake Evill has just graduated from the Architecture and Design faculty at Victoria University of Wellington, with a Major in Media Design and a Minor in Industrial Design.

The prototype Cortex cast is lightweight, ventilated, washable and thin enough to fit under a shirt sleeve.

For this to work, each patient would have a normal X-ray CT scan as for any other bone facture and then the arm would be 3D scan. With the use of software, a computer would determine the perfect shape giving the cast a denser structure around the injury.

In its creator’s mind, the cast will be printed directly in hospitals and directly positioned on the arm. As for a normal cast, it would also be remove on-site, but it might be recycled afterwards.

“At the moment, 3D printing of the cast takes around three hours whereas a plaster cast is three to nine minutes, but requires 24-72 hours to be fully set,” says the designer. “With the improvement of 3D printing, we could see a big reduction in the time it takes to print in the future.”

Approximately 6.3 million fractures occur each year in the U.S.. Jake Evill hopes one day this concept could be brought to market, so that more patient could benefit from the design and 3D printing technology.

Source: Dezeen.com / 3ders.org

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook