How to choose the right material for your 3D prints?

Posted By Arthur Cassaignau on Apr 30, 2015 | 1 comment

3D printing is not a unique process with just one material or one technology. In fact, when you’re looking for a 3D printed part, you can choose between many solutions and this choice will largely impact the outcome. Depending on where you are in the development lifecycle of your product, choosing the best material can be the key to your project’s success. Let us guide you through the process of picking the right material when you entrust a 3D printing service with the task of 3D printing something for you.

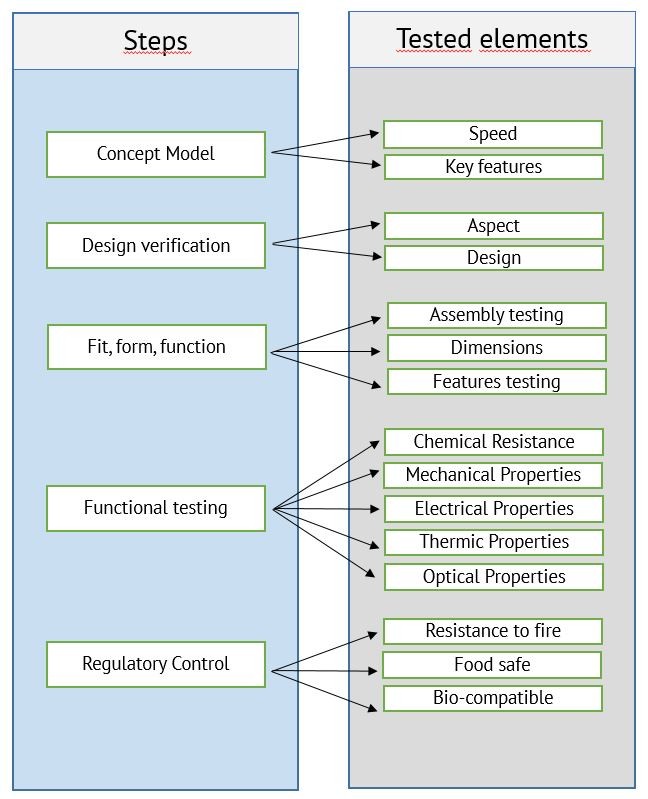

Creating a new product means two things. First, you need to find a way to prototype it. Second, you’ll have to industrialize the production once you’re satisfied with the prototype. To simplify your products’ develoment, we’ve created a chart to identify the key steps of your prototype creation, the key elements you’ll need to test and the properties with which you’re gonna have to play to achieve the perfect prototype in order to launch production. Let’s begin with some vocabulary.

Glossary for your Product Lifecycle Management

Concept Model

A concept model is used to test some aspect of the intended design without attempting to exactly simulate the visual appearance, choice of materials or intended manufacturing process. Such prototypes can be used to “prove out” a potential design approach such as range of motion, mechanics, sensors, architecture, etc.

At the early stage, Concept testing is useful to identify which design options will not work, or where further development and testing is necessary.

Design Verification

Engineering verification testing (EVT) is used on prototypes to verify that the design meets pre-determined specifications and design goals. This valuable information is used to validate the design as is, or identify areas that need to be modified.

The Model for EVT will capture the intended design aesthetic and simulate the appearance, color and surface textures of the intended product but will not actually embody the function(s) of the final product. These models will be suitable for use in market research, executive reviews and approval, packaging mock-ups, and photo shoots for sales literature.

Form, fit, function

The term “form, fit and function”, sometimes called F3 or FFF, in the manufacturing and technology industries is a description of an item’s identifying characteristics:

- Form: the shape, size, dimensions, mass and/or other visual parameters which uniquely characterize an item. This defines the “look” of the part or item. Sometimes weight, balance and center of mass are considerations in ‘form’. Color is not generally considered in ‘form’, except when it has a specific functional meaning.

- Fit: the ability of an item to physically interface or interconnect with or become an integral part of another item or assembly. This relates to the associativity of the part in relation to the assembly, or to other parts, and includes tolerances.

- Function: the action[s] that an item is designed to perform. This is the reason for the item’s existence, which also includes secondary applications.

Form, fit and function testing is useful to make the parts of an assembly, put them together and see if they fit properly. You can undertake a first evaluation of tolerances and check design errors.

Functional testing

A Functional Model is also called a working prototype. The functional prototype may be reduced in size (scaled down) in order to reduce costs. The functional Model helps you to test the parts when subjected to stresses and to check how the model will behave in its actual application. The construction of a fully working full-scale prototype and the ultimate proof of concept, is the engineers’ final check for design flaws and allows last-minute improvements to be made before larger production runs are ordered.

Regulatory Control

The regulatory control is a key step to control that your product will fit the legal requirements to enter a market. In this phase, you need to find the material and production method that will simulate very closely how your product can handle different elements like fire, electricty, or if it’s safe to use it near food.

Here is a quick visual summary of this process:

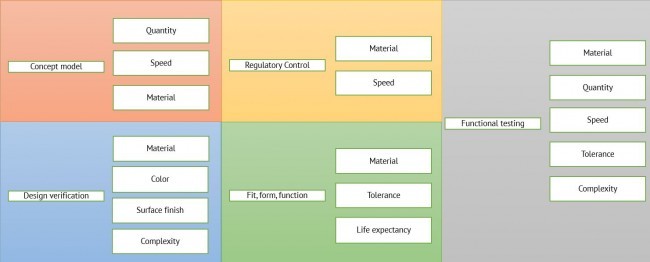

This calibrated process in which you begin with a concept model to end up with a fully functional prototype means that you don’t need to focus on all the aspects at the same time. Depending on your goal, you shoud use the multiple properties present in the different additive manufacturing techonologies. Here is a quick reminder at what you should be looking at depending on the phase you’re in:

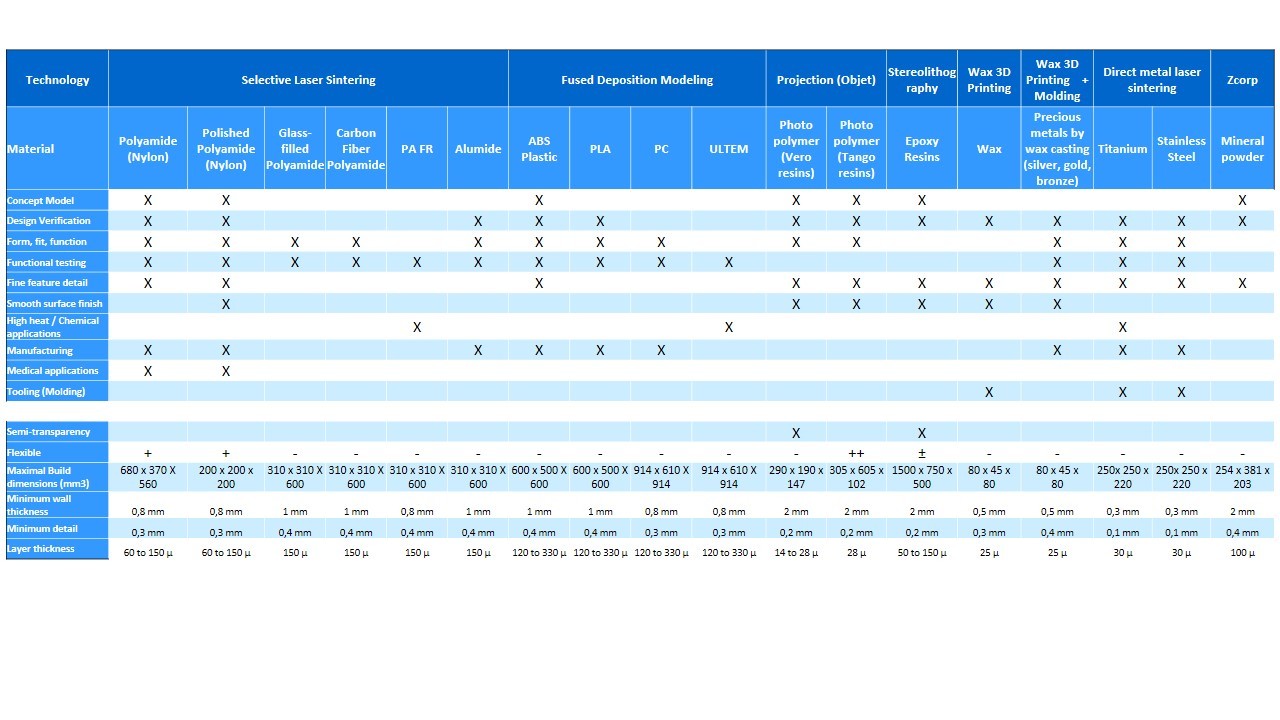

Now that you know everything you have to check to create the perfect prototype, we created a chart you can refer to when you want to 3D print an object with a specific purpose and chose the right material to simulate the right property. Take a look at it (by the way, all the material are available on our website):

Which material for which use? A chart of the different materials

To help you read it :

Fine feature detail

A fine detail is a very delicate, small, or exact part of an item. This material is appropriate for complex and delicate geometry.

Smooth surface finish

Smooth finish traditionally describes the removal of unsightly tool or machining marks. The material itself or a post-process such as polishing provide a very smooth final surface.

High heat / Chemical applications

Chemical applications require materials with specific properties. This material provides significant resistance to chemicals including acids, bases, hydrocarbons, fuels etc. This material has a low thermal expansion coefficient and a high heat deflection temperature, which enables you to use it for high heat applications.

Manufacturing

This material can be used to make goods or wares on a larger scale than prototyping. This means that this material can be life tested (i.e. how the part will behave during the life time of the product) and used in regulatory testing.

Medical applications

Medical applications such as use in surgical instruments or medical devices requires specific properties such as biocompatibility. This material can be in contact with human or animal bodies, inside or outside the body, and will not have any toxic or injurious effects on biological systems.

Tooling (Molding)

This material can be used to create tools for a manufacturing process. For instance, wax is used to create the counterparts of a mold before casting.

That being said, we always provide guidance and support for all your project around 3D printing. Don’t hesitate to contact us directly at [email protected] or on Facebbok and Twitter.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook