3D Printing Aids Product Development

Posted By Jess Hedstrom on Jun 11, 2015 | 2 comments

The journey required in taking an idea from conception to finished product is a very long process. Finding the idea is generally the easiest part. Finding the money and inexpensive resources to manufacture are generally the hardest… until now. Thanks to 3D printing technology; the pivot away from injection molding to 3D printing in the first stages of iteration has saved money and time for many hardware product developers, let’s dig a bit deeper to find out how.

Injection molding is a common manufacturing process in which a mold is created (usually out of metal) and melted plastic is injected into the mold. This process is used to make many of the everyday objects from our toothbrush or sunglasses to our cars. And generally the process of creating the mold (seebelow) is the most expensive process, but if you decide you want to change the design you’re going to need to have another mold created.

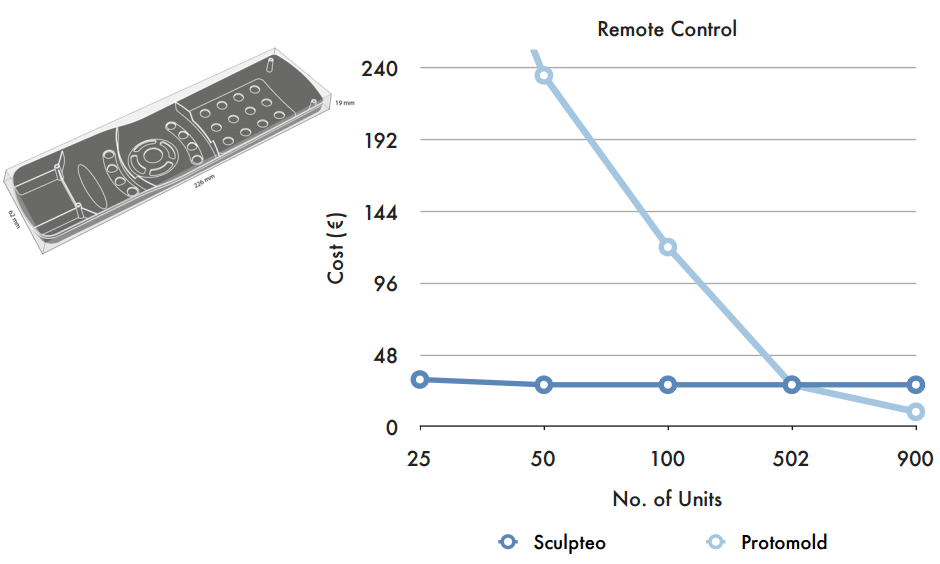

3D printing is the process of modeling an object digitally, then bringing it to life by sending it to a printer. 3D printers place thin layers of material on top of one another until your object is finished.Here we have 2 very different types of manufacturing and it’s sometimes hard to determined which is better for the product that is being created. Many people need to base their decision on the cost to manufacture. The image below shows the cost of production for a TV remote using 3D printing (or additive manufacturing) vs. Injection Molding. This chart was provided from 3D printing servicer Sculpteo, if you’d like to see 4 additional examples you can find those here: 3D Printing vs. Injection Molding (29 pp., opt-in).

We can see from Sculpteo’s report that in the case of the TV remote injection molding with Protomold becomes a better option than 3D printing when you hit 502 units. prior to that you would save more if you chose to have your item 3D printed. This is a great example of batch printing which is the process of uploading a file to a servicer and having 20+ identical items created. Instances when this would be helpful are prototyping, QA testing, Beta testing a design… etc. From an entrepreneur’s perspective, ordering a small batch, and distributing them to customers for feedback is a dream come true.

A lot of the risk is removed with the help of small batch printing because companies have the ability test the market with multiple different versions of their product, but ask the chart states once you’ve found a great iteration that your customers like, there will come a point when injection molding is a reasonable option. With rapid changes in technology I see the market opening wider for entrepreneurs and and businesses making products, industries such as wearable technology and IoT will begin to expand as a result of these improvements. If you are an entrepreneur and you’re interested in learning more about injection molding vs. 3D printing, check out Sculpteo’s e-book for a more in-depth analysis.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook