3D Printing resolution on Alumide: the complete Q&A

Posted By Arthur Cassaignau on Jul 29, 2015 | 1 comment

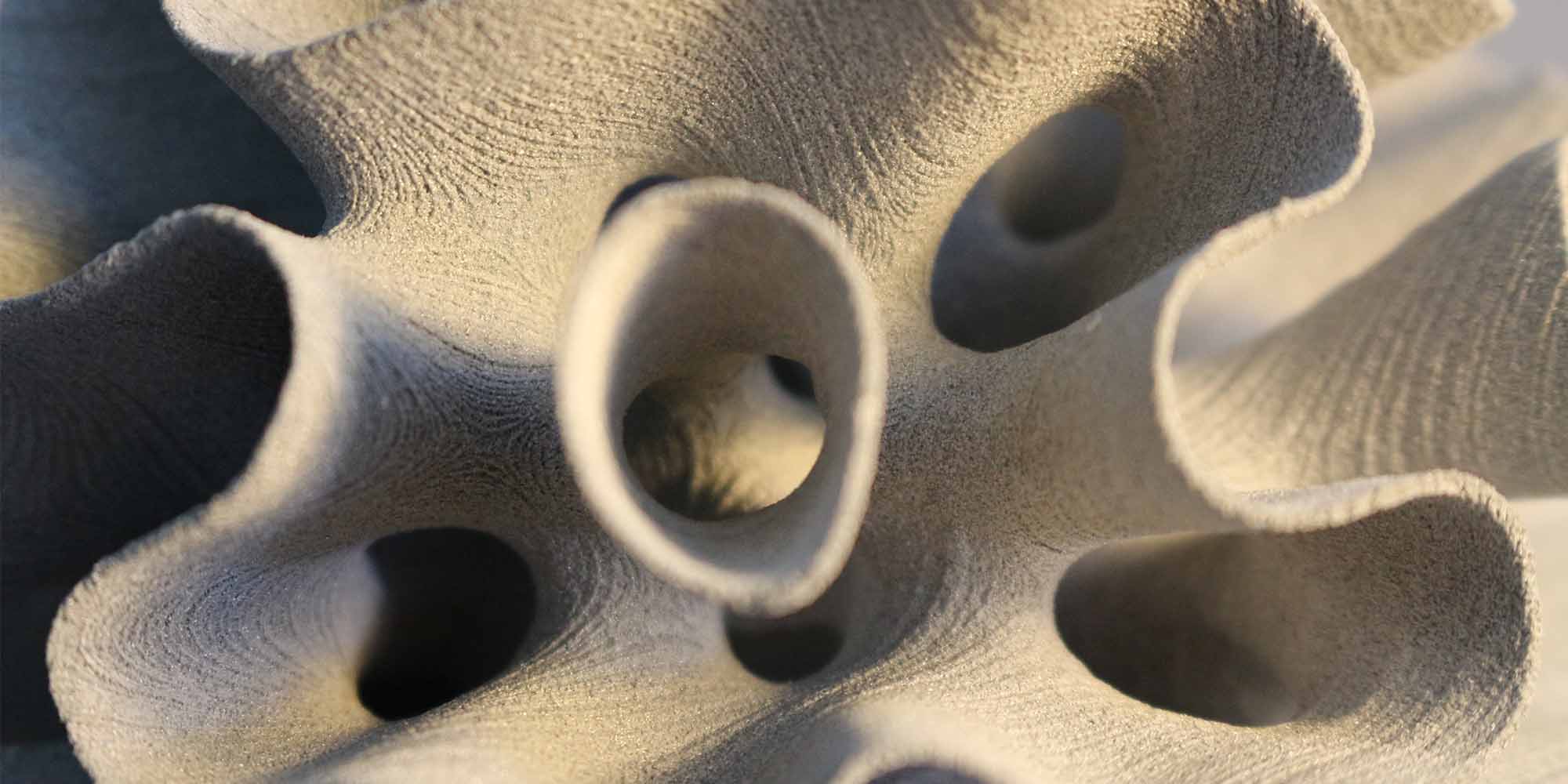

When looking at 3D printing an object with the benefit of the SLS 3D printing technology, there is more than regular plastic. One of the material offered by SLS 3D printing is called Alumide. It’s the perfect material to create stiff parts that need a metallic appearance, that are subject to low stress and that can resist high thermal loads. It makes it the perfect candidates to create part for prototyping and testing. Now what about its 3D printing resolution and the precision that you can achieve with it? Matthew, process engineer at Sculpteo, explains the process in detail and give tips for your prototyping parts.

- A lot of 3D printing users know SLS 3D printing to produce high quality plastic parts. What other materials can you print with SLS technologies?

Alumide! and a lot of others too. SLS 3D printing is a technology that is powder based. It uses a laser to sinter a thin layer of raw material powder. The process is then repeted until the completion of the object. That being said, 3D printing users consider the technology to create plastic parts as its the most common kind of SLS 3D printing. In the case of plastic SLS 3D printing (as the one we do at Sculpteo), the raw material is polyamide (PA12), but you can find other kind of powders with properties that are different from polyamide. Alumide is in fact a combination of polyamide and aluminium. The aluminium is what gives the metallic appearance to the part and its strengh.

In other words, it bridges the quality of both polyamide and aluminium in a 3D print. Parts created in Alumide enjoys a good machinability, high temperature performances, a well-balanced ratio of density and stiffness with a good dimensional accuracy.

- Especially on dimensional accuracy, here is a good question. SLS 3D printing is known for being an accurate and repeatable process. Is it the case for Alumide too?

Absolutely! We already explained what is being done for our plastic part on that level in a previous post and we basically apply the same process for Alumide. As a lot of our clients produce either prototypes or parts for production, the calibration of our machines and the quality control is very strict to ensure that each part is gonna be the same. We do it for our Alumide parts so that clients can use it from the prototyping phase to the production phase. If you creating a mold based on your prototype made with our Alumide material, we know that you need to have the highest possible accuracy. That being said, there are limitations to the technology, and there is a limitation between the dimensions of a CAD file and the dimensions of the final product.

- How does the laser sintering factor the printing resolution?

As we already discussed, 3D printed Alumide is produced by SLS technology. During the 3D printing process, the laser melts consecutive layers of polyamide powder to solidify the shape of the object. So the laser is working in X and Y dimensions and the printer builds the Z dimension by adding thousands of layers. This means that we cannot expect the same tolerance in X and Y dimensions on one side, and in the Z dimension on the other side.

Let’s start with the Z dimension, which is the easiest. When you are creating your 3D file, you have to keep in mind that we cannot be more precise than the thickness of one layer. The layer thickness we offer at Sculpteo for Alumide is 150 microns. So there’s no need to be more precise than the layer thickness. Let’s take an example: you are designing an object with a Z dimensions of 2.675 cm and you want to get it 3D printed on 150 microns printer. At Sculpteo, we will 3D print a Z dimension of 2.67 cm.

The X and Y dimensions are impacted by the diameter of the laser. Standard laser have a diameter of 400µ on the smallest SLS printers and 700µ for the bigger ones. As you can see, the size of the laser’s diameter is an important factor for respecting the dimensions!

The last factor is the thermal shrinkage. The build chamber and the laser are heating the powder during the 3D printing process and then cooled down. That results in minor shrinkage of the final object. That retraction is an effect of the change in temperature. So for each printing batch, we have a set of cooling techniques which ensure the most accurate prints with respect to the 3D model.

- Which tolerance are you assuring at Sculpteo?

The polyamide objects we 3D print have a maximum precision of ± 0.5mm for pieces 99mm or smaller and a global precision of ± 0.5% for pieces 100mm or larger. For parts that are less than 1.5mm the tolerance could be higher due to the laser’s diameter.

- I have printed an object 2 months ago and I need to reprint one : would it be exactly the same?

Not necessarily. If you plan to have several part printed, consider ordering them in a batch, you will have a better consistency on printing 10 X 1 item in a single job instead of printing 1 item in 10 different jobs.

- How can I calculate in advance the maximum tolerance that would apply to my design?

I have created a form that will give you an idea of the maximum and the minimum dimensions of our SLS printers.

Here you can enter the dimension you want to check (for example 1.234):

mm

Will give you a dimension between:

mm and mm

I recommend to have a look on our design guidelines to prepare your model in any case.

- If I receive an object that doesn’t respect this tolerance, what should I do?

We apply different quality control methods on batch controlled items and single 3D prints. For single 3D prints, a part of our quality control consists in random picking of parts in our production workflow to validate that the tolerance is respected. But it’s not 100% and it happens that we send a part that is not respecting the tolerance. In this case, you need to send an email to [email protected] with a picture of the part and your order reference. If you can show the measure with a caliber, that quickens our the verification steps! In every case, we will reprint your object right away at no cost to you.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook