3D printing for mechanical engineering

Posted By Lucie Gaget on Mar 1, 2019 | 0 comments

You know it, applications of additive manufacturing are numerous. Today we are going to focus on the mechanical engineering applications of this cutting edge technology. Do you know that 3D printing could help you on many levels for your mechanical projects? From developing your prototype to the improvement of your designs and the optimization of your inventory, additive manufacturing could really offer you great benefits with your mechanical parts.

Let’s see how you 3D printing for mechanical engineering could help you!

Benefits of 3D software for mechanical engineering

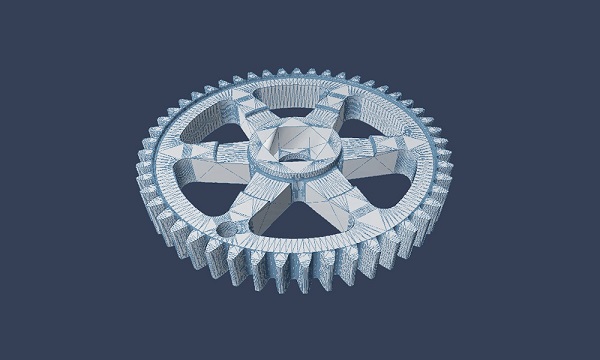

First, before even thinking about 3D printing your project, you will have to use a 3D modeling program to create your 3D file. And if you want to do it all by yourself you will have to choose the right software for you. Among all the tools these programs are offering, visualization will be one of the most useful for your mechanical project.

Using visualization software or 3D modeling software with great visualization options can help you to get a better overview of your project, especially if you are working on mechanical or technical parts. This 3D process will allow you to adjust and improve your parts quite efficiently. It is also a good method to correct the last errors that you have maybe missed while creating your 3D design.

You need to find the best way to design a concept and show it to your customers? 3D visualization is certainly the best method you could find! You can easily modify your model with your ideas, and the customer’s inputs.

If you are working on mechanical projects, you certainly know that design and analysis are essential. That is why we recommend you to use software with great analysis features, or another software tool, entirely dedicated to simulation and analysis, such as ANSYS. Check out our selection of the best 3D modeling software for mechanical engineering projects.

Now, let’s see how going further with 3D, and using 3D printing could totally help you improve your work!

Why you should use 3D printing for your mechanical engineering projects

Optimize your design!

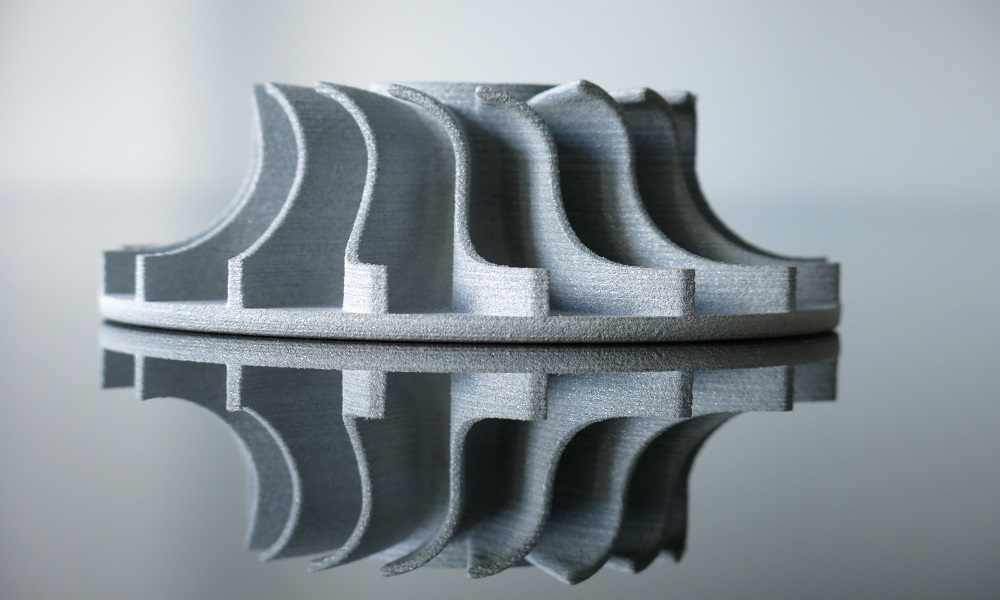

Do you know that you could maximize the performance of your mechanical system by optimizing its structure? Topology optimization could clearly help you improve your project. Additive manufacturing opens a lot of possibilities when it comes to design and topology optimization, allowing you to find the best compromise between strength, weight and production cost for your mechanical parts. From a 3D file, we can print your parts regardless of their complexity! In any project, the design is the key, and especially for technical projects, with complex geometries.

What if you don’t have the design skills to optimize your project? Don’t worry, at Sculpteo, we can help you with that. Our 3D printing experts from Sculpteo Studio are here to help you create your project from scratch or optimize an existing 3D file.

Use the best 3D printing materials

By using an online 3D printing service such as Sculpteo for your project, you will have the chance to choose the material of your project among all the 3D printing materials available in our catalog.

Do you need plastic or metal? Make your choice, upload your 3D file and get your online quote instantly. For further questions about materials properties, check our 3D printing materials pages, or contact our sales team, they will answer all your questions. Do you need flexible parts? Or parts resistant to heat? Let’s find out together what’s the best 3D printing material for you!

3D printing will save your time

Additive manufacturing will speed up your manufacturing process. Indeed, proof of concepts or prototypes can be improved using 3D printing technology. 3D printing is the perfect manufacturing method to use if you need to do some rapid prototyping. Using 3D modeling software, the creation and test of your designs will be significantly accelerated.

By using 3D printing you save time on your assembly process. Mechanical 3D printing enables the production of a batch of parts that are traditionally made of many components. But thanks to this cutting edge technology, you will be able to reduce assemblies and welding steps! This manufacturing process will help you save time, you will get the chance to produce faster.

The opportunity to improve your supply chain

The improvement of the supply chain is quite a big subject to go through. But what if you could considerably reduce your inventory by producing on demand? We can tell you that additive manufacturing is certainly the best solution for you to make your mechanical parts.

Do you need prototypes, spare parts or small quantities? Stop wasting your time and money! Start using 3D printing right now.

Mechanical projects, making the most of 3D printing

Aeronautics using 3D printing

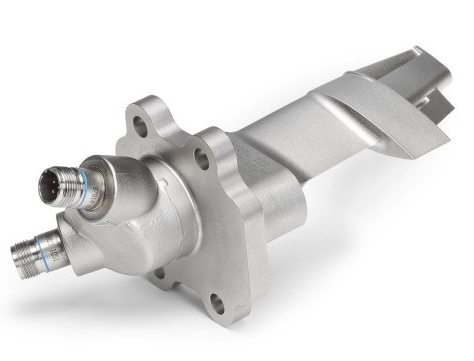

This may look like an ordinary nozzle, but if you look closely you will notice this is all one part thanks to 3D printing. This is GE’s Aviation fuel nozzle and in the not so distant past it was made up of 20 different parts, not only is the 3D printed version of this nozzle 5X stronger, it also lasts longer.

Generally, the quality assurance process fixes issues like strength and durability by isolating and analyzing the issue, then by correcting and implementing the correction on the newer version. 3D printing speeds up the QA process sometimes by months, 3D printing does this by shortening the time between correcting and implementing. Obviously, it also saves a lot of time on assembly.

Automotive industry

It is becoming more and more common in the automotive industry to use additive manufacturing. Indeed, 3D printed car parts are now a reality. To develop new designs or create car parts, 3D printing can now be useful on many levels for car manufacturers. The accuracy and the access to robust materials such as metal materials enable the development of 3D printed mechanical parts!

Are you ready to make the most of additive manufacturing for your mechanical project? Upload your 3D file right now, or contact our sales team. They answer all your questions about this 3D manufacturing process!

Feel free to subscribe to our newsletter and get all tips about 3D printing applications.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook