Structures that can change shape with 4D Printing

Posted By Arthur Cassaignau on Jan 27, 2016 | 0 comments

4D Printing is a term that seems to appear more and more these days. It is used to designate a technology which allows the manufacturing (with 3D printing) of objects that will change their shape after they have been produced. Often the shape changes because its own environment is transforming; like being being immersed in water or by bringing the temperature down. This is not fresh news as such, since we already talked about this in previous posts, however Harvard’s engineers pushed it even further this time.

Inspired by plants that change shape over time when exposed to external stimuli , the team used a special hydrogel composite to produce preformed shapes when the 3D print is immersed in water. Jennifer A. Lewis , the lead author of the new study and CEO at Voxel8 , states that ” this work represents an elegant advance in programmable materials Assembly , made possible by a multidisciplinary approach. We have now surpassed integrating form and function to create transformable architectures . “

The study has been co-lead by two other authors A. Sydney Gladman, a graduate research assistant advised by Lewis, who’s specialized in 3D printing polymers and composites; and Elisabetta Matsumoto, a postdoctoral fellow advised by Mahadevan, specializing in condensed matter and material physics.

If you want to understand more about this process, watching the video below is very helpful.

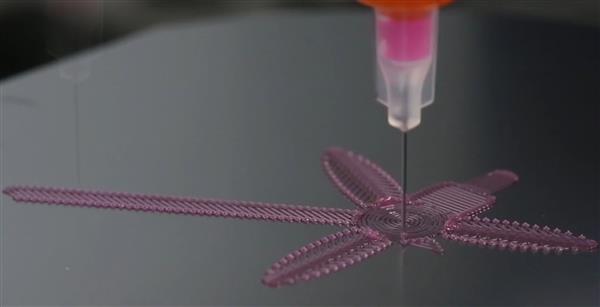

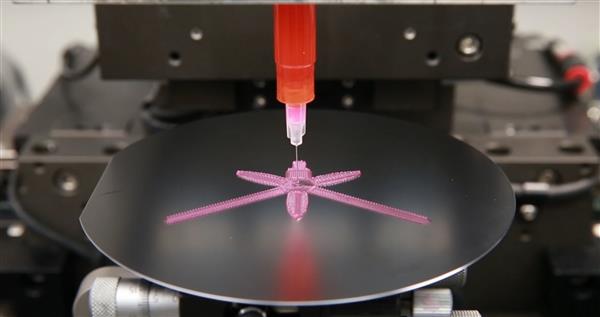

In this project, the team from Harvard took cellulose fibrils from wood in order to turn them into an hydrogel composites. By carefully determining the position of the hydrogel composite ink using additive manufacturing techniques it is possible to program the output of the material. That means that the order in which it swells and stiffens over time can be “pre-programmed” into the product itself.

A press release for the paper describes this process in this way, “Like wood, which can be split more easily along the grain than across it, the hydrogel-cellulose fibril ink undergoes differential swelling behavior along and orthogonal to the printing path when immersed in water. Combined with a proprietary mathematical model developed by the team that predicts how a 4D object must be printed to achieve prescribed transformable shapes, the method opens up potential applications for 4D printing including smart textiles, soft electronics, biomedical devices, and tissue engineering.”

Numerous industries are interested in the result of this project, since being able to predict or even better program how a material will react to an external stimuli makes it extremely attractive. this is particularly true for fashion, electronics medical devices or even aerospace.

To push the example even further, the team at Harvard produced two exactly identical flowers and demonstrated that their shapes shifted completely when they were immersed in water. The Gif below shows the flower shifting from its original shape to its second state.

Matsumoto suggests that “our mathematical model prescribes the printing pathways required to achieve the desired shape-transforming response. We can control the curvature both discretely and continuously using our entirely tuneable and programmable method.”

The research is partially being funded by the Army Research Office (ARO) and the National Science Foundations’ Material Research Science and Engineering Center (MRSEC). But there is no doubt that it will raise a lot of interests among private companies too.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook