Carbon 3D Printer: Introducing the CLIP Technology in 3D Printing

Posted By Arthur Cassaignau on Mar 1, 2016 | 0 comments

The Carbon 3D printer has been revealed to the world for the first time last year. Since a few months, we’ve been working hand in hand with the team from Carbon to be the first to offer their CLIP 3D printing technology online on our 3D printing platform. Starting today, you are able to order 3D prints from the Carbon 3D printer in a wide range of different new and innovative materials. From prototypes to finish parts, the path from 3D modeling to high end manufacturing has never been faster.

We are very excited to introduce the CLIP 3D printing technology on Sculpteo. As a partner of Carbon, we are currently the only online 3D printing service to own a printer of this type in our San Francisco Bay Area facility. Along with this new technology, we are also unveiling a series of new resins ranging from rigid to flexible, all of which are supported by the Carbon 3D printer. These resins make it possible to prototype an enormous range of products (from load-resistant mechanical parts to seals and flexible containers) at very high resolution, as well as producing commercial quality parts. These materials have been designed to respond to key engineering requirements, from the elongation and strength expected of injection-molded elastomers to the temperature resistance of a nylon-glass composite.

“We are really excited to announce our partnership with Sculpteo. Their work with our machines will allow anyone, from small startups to large corporations, to gain access to CLIP and our portfolio of game changing materials.” said Phil DeSimone, VP of Business Development at Carbon

How does the CLIP technology work?

Carbon’s CLIP-based technology combines the engineering-grade properties of thermoplastics with exceptional resolution and surface finish. It makes a range of features and applications possible for industries as varied as automotive, medical and consumer electronics.

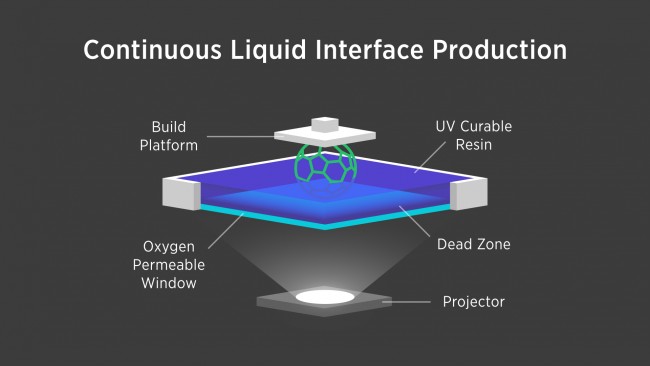

CLIP, which stands for Continuous Liquid Interface Production, eliminates shortcomings of other 3D printing technology by emphasizing a tunable photochemical process over a traditional mechanical approach. CLIP works by projecting a continuous sequence of UV images, generated by a digital light projector, through an oxygen-permeable, UV-transparent window below a liquid resin bath. The dead zone created above the window maintains a liquid interface below the part. Above the dead zone, the curing part is drawn out of the resin bath.

What does the Carbon 3D printer change ?

Carbon’s CLIP works to eliminate many of 3D printing’s issues. The technology itself, thanks to its continuous 3D printing process, allows to create parts with no visible layers. While additive manufacturing users are used since years to the specific stairs effect and rather rough finish of 3D printed parts, the CLIP technology offers the possibility to create both prototype and end use parts that will have a smooth finish and almost no visible layers.

Also, this continuous 3D printing process makes it even faster to 3D print an object. While most additive manufacturing processes require a long time to built one layer and even sometimes time to prepare the next layer (as it’s the case with SLS 3D printing), the CLIP technology reduces those to steps to their minimum. The result is the ability to create parts in a very time efficient way, the 3D printing process itself being quicker than on any other technologies.

What kind of material are we able to use with the Carbon 3D?

Carbon has created a diverse and growing selection of materials that enable product designers and engineers to build functional prototypes and production parts. We currently have seven Carbon materials available for use. The materials were designed to meet common engineering requirements — from the elongation and resilience expected of an injection molded polyurethane elastomer to the temperature resistance of a glass-filled Nylon, and many more.

If you want to know more about the different resins offered on the Carbon, you can take a look at the specific CLIP resin page on our website.

How to start 3D printing with the CLIP technology?

We are the first online 3D printing service to integrate the CLIP technology and offer it to our users directly online and worldwide. The CLIP technology and Carbon printer is available starting today on our website through a special CLIP pilot program designed to let our user discover the technology and access it while being helped throughout the process. You can of course learn more about the CLIP pilot program or access it on the Sculpteo website.

We hope you’re as excited as we do about this.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook