How can you implement 3D printing in your office department?

Posted By Claire Chabaud on Mar 9, 2016 | 0 comments

In our series “How will 3D printing change your job ?”, we made a broad focus on different industries analysing how the innovation can change for instance the manufacturing process of a particular sector. However, on a more human scale 3D printing can also change the way you work in your department. In this article, we are less addressing how the technology is going to change your job in the future rather than how you can use 3D printing as a daily tool. Then let’s have a look at practical examples of how you can implement 3D printing in your daily task!

How can you implement 3D printing in the Marketing department?

Today 3D printing can be an innovative tool for your communication support. Your customers might not be used to the technology yet and will be curious to discover it. For example, the FrenchTech movement needed to create a badge to represent the logo but also to show some innovation. Then they 3D printed emblem to wear during FrenchTech events. The badge is at the same time an intriguing object for your customer but also an excellent medium of communication for your brand.

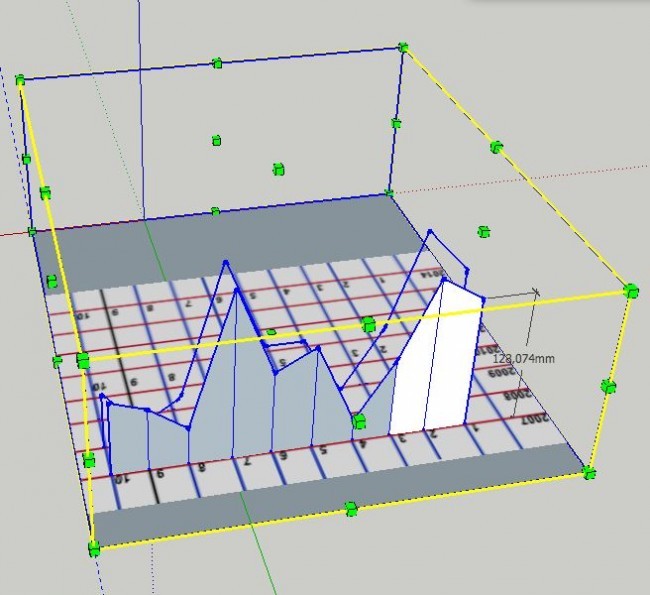

In a more strategical viewpoint, 3D printing can help you to visualize data as 3D printed sculptures. As Volker Schweisfurth creator of “MeliesArt” explains how he realized how small the retention rate is for most of the statistical data that we read on a weekly basis. It doesn’t stick with us, we usually forget more than half of it. “Digital is easy to forget, but analog is made to remember”, he said. Then MeliesArt help. An innovative tool for your presentation or meeting!

How can you implement 3D Printing in the Commercial Department?

If you are working in the business office, then you are probably thinking about how to create the most personalized product or service for your customer. Often it is a tricky and costly strategy. However, with 3D printing whether you produce ten identical goods or 10 different the cost is the same. Indeed, additive manufacturing allows the possibility of mass-customisation, which means that you can produce a series of products with every item personalized.

Companies in different industries are implementing this strategy. For example, Nike, Adidas and New Balance want to use a 3D scan of their clients foot to 3D printing custom soles in TPU. The idea is to create a unique product but manufactured in a mass-production. If you want to discover what is at stake in this industry, Andrew Zaleski wrote an interesting article on this three shoe race for Fortune magazine. To implement such mass-customisation there are three main steps:

- First you need to build the interface to capture the personal data.

- Second, you have to transform the customer’s data into a topological representation of the product. For these steps the help of an IT department or computer engineers and 3D designers is critical.

- Eventually, you need to find at which cost you should estimate this possibility of customization and for which market. With the evolution of 3D printable materials and technologies, mass-customization will be more accurate and adjustable to any industries.

Midway between the Commercial and Marketing departments uses, Skoda used 3D printing and mass-customisation for the launch of a campaign for its Fabia. As a customer, you could customize a Fabia online and then get your 3D print directly to your local Skoda dealer. The purpose of this campaign was to intrigue the customer so he will come to get the print and do a Fabia test-drive. An interesting way to mix digital and concrete marketing and commercial strategies.

How can you implement 3D printing in the Financial Department?

Using 3D printing is also a concern for the financial department. However, it is less about a disruptive way to work rather than a financial strategy to implement. Depending on the technology you choose, 3D printing can be a costly investment in terms of time, staff and money. Then if your company wants to use it, there are three main ways to access the technology.

- Buying a 3D printer. It is important to keep in mind the cost of a professional printer with SLS technology with a first entry price from 35 000 $ to more than 1 million $ Nevertheless, personal 3D printers with FDM technology have an entry price under 500 $.

- Leasing a 3D printer. Depending on the technology, it could be a useful solution to test if it’s the one fitting your needs.

- Outsourcing the 3D printing technology by using a 3D printing service or integrating an API.

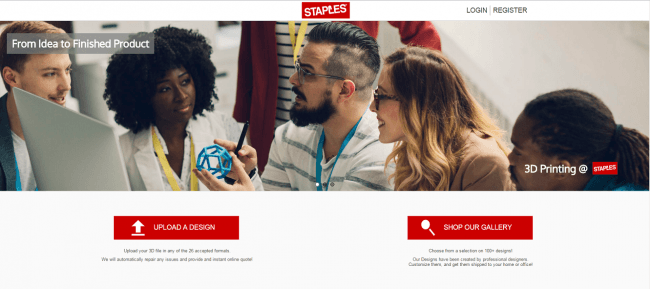

Staples’ strategy is a prime example to understand which option to pick. The giant American retailer was among the first to develop a service where customers could walk into a store with a 3D file and walk out with a 3D printed part within a few hours. So, at first, they decided to buy personal and affordable 3D printers. It allowed them to test the market for it. However, when they were seeking for a more professional technology they choose to integrate our A.P.I. It means that they offer a professional 3D printing service through a white label website. When a client makes an order, it’s directly passed to our factory and then delivered under Staples brand. Choosing both options allowed them in terms of financial strategy to keep the control on their spendings.

How can you implement 3D printing in the Production Department?

Regarding the product development, additive manufacturing is an amazing tool to accelerate the prototyping iterative steps. Indeed, while you elaborate the design, you can directly materialise it and optimise it right away on your 3D file. No need to create a mold to change some part of your prototype. It is a significant change in your product creation that can even divide the time of this step by 5. If you want to discover more deeply how 3D printed prototype can be adequate for your project, Arthur Cassaignau detailed this use in this article.

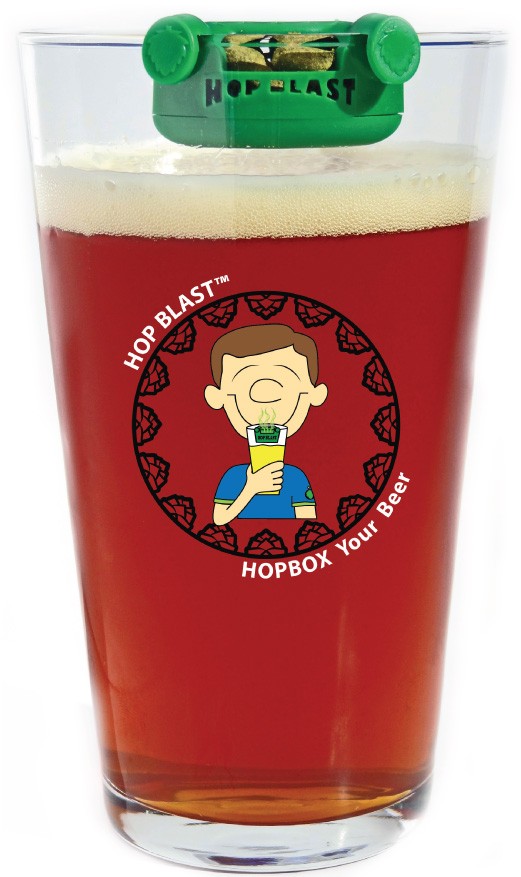

For example, the HopBlast Company succeed to create an entirely disruptive new product to enjoy the hop of your beer. This product is nothing like you ever seen before because they simply made a prototype of their idea with a small budget and no knowledge of CAD software, 3D modelling or even 3D printing.

Nevertheless, it’s important to keep in mind that 3D printing is not only a mere mean of prototyping. It is also a way of production for small and medium series. With the material and technology improvements, the cost is significantly decreasing allowing the technology to be a feasible manufacturing process. During our State of 3D printing report, 17% of the respondents stated that they are using additive manufacturing for production.

How determine if 3D printing is suited for your production needs? Well, the technology is efficient on four aspects;

- Realise complex geometries with shapes with intricate designs for instance

- Mass customization to personalize thousand of products with your customer personal data

- Integrated assembly of your object directly with the 3D model

- Engineering redesign to optimize your parts without the production of a tool.

For these technical aspects, AudioQuest decided to produce approximatively 40,000 3D printed parts of its NightHawk headphones. They created a complex biomimetic grille with an intricate diamond cubic latticework that couldn’t be made by traditional manufacturing process due to the structure complexity. In this project, 3D printing was an efficient manufacturing process as it allowed at the same time to produce a significant quantity and a shape that couldn’t be made with another way of production.

The 3D printed grill assembled in every Nighthawk headphones. It mimics shapes from a butterfly wing.

How can you implement 3D printing in the Human and Resources Department?

The HR department has a crucial role to play to help the transition for the employee with the technology. There are many ways to do so. Either by promoting 3D modeling learning or by giving free access to a personal 3D printer so the employee can get familiar with the process. As we saw with the HopBlast experience, the basics of 3D modelling can be assimilated rather quickly with online tutorials or training. The main challenge for the HR department will be to make the technology accessible to everyone. This e-book is full of resources to raise the employees awareness and help them find a way to learn more about 3D printing.

How can you implement 3D printing in the Research and Development Department?

According to the industrial sector of your company, 3D printing technologies and materials might not be suited for your professional uses yet. Then, having R&D department dedicated to this subject on its own or with a particular partner can be an effective solution to create a disruptive use of the technology in your company.

For example L’Oreal, one of the biggest French cosmetic giants is partnering with Organova to 3D print living skin. In this way, L’Oreal R&D department tends to fasten the development of the technology needed for the singularities of its business.

Another vision would be to use 3D printing to create a breakthrough innovation. Indeed, when you try to create a disruption, something that has never been seen before, often you need innovative tools that no one has created yet. 3D printing can be the exact help you need to design the tool that will help you to create a new process.

For example Florian Voineau, a Ph.D. researcher, tells us more about the use of 3D printing in his department at the Laboratory for Integrated material to the system of Bordeaux. His team works on the conception of microwave frequencies. They try to find a way to enhance the frequencies of the electromagnetic waves. To do so, they 3D printed a waveguide with a disruptive shape to explore new possibilities.

These are few practical examples of how to implement the technology in your professional projects, and there are even more ideas to explore! If you think of other application in your department, feel free to leave a comment or contact us to talk about it.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook