Glass 3D Printer by MIT: an exclusive interview with Dr Pierre-Thomas Brun

Posted By Sculpteo on Mar 16, 2016 | 0 comments

MIT hosts some of the most prolific labs when it comes to 3D printing! It excels in various fields such as design, materials or 3D printer. Dr. Pierre-Thomas Brun is a young French mathematician based at MIT and a member of the team that created the amazing molten glass 3D printer – which they call “viscous sewing machine“. He kindly accepted to answer our questions.

Dr. Pierre-Thomas Brun is an Instructor in Applied Mathematics at MIT. Prior to joining MIT in 2014, he received his B.Sc and M.Sc from Ecole Polytechnique and Cambridge University, and his Ph.D. from Université Pierre et Marie Curie. He pursued his postdoctoral studies at EPFL, in Laboratory of Fluid Mechanics and Instabilities. On his blog – Science I do – this is how he presents his work:

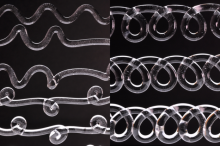

“My research is concerned with the mathematics driving the world that surrounds us, from mundane situations such as the coil formed by honey falling onto a toast to the self-similar solution describing the curling of blood cells during egress of malaria parasites. I concentrate on studying the dynamics of fluids and flexible solids, with particular attention given to non-linear effects which I explore combining table sized experiments, precision numerics and theory. I strive to take the best out of these complementary tools to rationalize the physics underlying such systems. “

After a long discussion within the team Sculpteo, we focused our interest on 9 questions, which Pierre-Thomas very warmly agreed to answer. Here they are:

By perusing your previous work, our first question is: how do we go from the flow of honey on slice of bread to molten glass?

Is the process very unstable? E.g. Do we have to control the temperature to the nearest tenth of a degree?

The FDM technology allows experimenting a large range of viscous materials. Do you think that other techniques could be used to 3D print with glass? We think more to the drop technology rather than the powder technology.

During a layer deposition, is the previous layer still viscous and is there a risk of collapsing? If the solidification of the previous layer already happened, won’t the final object be too fragile and highly anisotropic?

What is the maximum size on the XY-plane we can print?

Do your equations perfectly predict the shapes realized by the fluid whatever the characteristics of the deposited material are. Is there of the empirical?

Do you think that spider may have an intuitive knowledge of these equations?

Our readers will probably have the same question, what would be the price for a prototype of your first machine?

Do you think that there is enough math in 3D-printing or would the engineer gain by working closer to mathematicians?

If you want to know more about 3D-printing with molten glass, we recommend this BBC report to you. You can also visit the personal website of Dr Pierre-Thomas Brun.

Until you can print (one day!) glass at Sculpteo, you can consult our list of incredible 3D-printed materials or download our ebook “The 3D Printing Material Bible“.

Pictures from PT Brun.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook