Truth or Fiction: 12 Additive Manufacturing Topics

Posted By Jess Hedstrom on Mar 16, 2016 | 0 comments

From 2011 to the present day the press has continued to report on the magic that is “the 3D printer”. Additive manufacturing has turned into the sexiest form of manufacturing, and (AM) has left traditional manufacturing searching for its place in the spotlight. The technology of additive manufacturing is currently being used very inventive ways that boarder on Sci-Fi, which is why it’s sometimes hard to separate the truth from the fiction.

Below are 12 topics regarding additive manufacturing that we will identify as Truth or Fiction…

1. The additive manufacturing (AM) market is unstable = FICTION!

According to Wohlers Report 2014, the worldwide 3D printing industry is now expected to grow from $3.07B in revenue in 2013 to $12.8B by 2018, and exceed $21B in worldwide revenue by 2020. Wohlers Report 2013 had forecast the industry would grow to become a $10.8B industry by 2021. Prototyping (24.5%), product development (16.1%) and innovation (11.1%) are the three most common reasons companies are pursuing 3D printing. An extensive survey of 3D printing adoption that we published in 2015 titled The State of 3D Printing stated that 44% of respondents claimed they will increase their spending on additive manufacturing by 50% or more this year. Just yesterday we saw that 3D printing manufacturer 3D Systems rose nearly 3 points on the stock exchange this week. Industry investors have had their eye on the company as their stocks declined and some have even used their story as a sign of trouble in the industry, but this week they have announced an almost 25% uptick in their Q4 financials. Once again no one knows what this industry is capable of, but with companies like Staples, HP, Amazon, Ford, Johnson & Johnson and many more adopting 3D printing the industry is becoming more stable than it has been in the past.

2. You can manufacture both circuit boards and enclosures with 3D printing = TRUE!

The thing is, most electronics are typically two-dimensional. Layers upon layers of relatively flat PCBs make up the brains of every bit of technology we know and love. The funny thing is, we live in a three-dimensional world, and we like to shove these flat circuits into three-dimensional enclosures. Be they boxes or cylinders 3D printed circuitry can now be printed right along side (or even integrated into) plastic enclosures. It’s pretty amazing! The only draw back that we can see is servicing the product. But due to the relatively low cost of manufacturing and the decreased wait time, that wouldn’t be an issue. We’ve seen some great designs over the years attempting this, but it’s only recently that we’ve seen working versions of this. Companies like Voxel8 are working hard to create FDM quality enclosures with the circuitry integrated into the housing. It is your standard run of the mill FDM style 3D printer, but it has a 2nd extruder that is capable of squeezing out liquid silver ink that dries at room temperature. For more information about 3D printed circuits check out the Sculpteo blog, we feature an article that breaks down this practice.

3. Get rich today with 3D printing = FICTION!

For some reason, the less a person knows about 3D printing and its complexities, the more money they want to put into (some part of) it, to gain a theoretical competitive advantage and exploit its potential. It’s time for a wake-up call, that is not how it works. The “Get Rich Quick with 3D Printing” model does not work for two reasons. The first reason is that although AM is in the early phase of what could be a decades long growth curve, there are people who have been working with the technology for over 30 years and therefore have a 30 year lead of experimenting and perfecting their process. To quickly jump into the industry, and jump out a millionaire is almost impossible.

The second reason is that 3D printing is different. It is more about the enthusiasm of being a pioneer and creating new methods or materials! It’s about seeing up close what AM holds for future. It is an industry for visionaries, and lovers of manufacturing.

This, however, does not at all mean you cannot make money, because you most definitely can! You can even make a decent living but the key is to grow with the industry. This is how the 3D printing revolution will unfold: by more and more tenacious creative people creating businesses with AM technology instead of traditional manufacturing. The more people who use this technology, the more we will figure out the capabilities of the tech for stories from engineers and entrepreneurs that have used 3D printing to start their business you might be interested in our Sculpteo customer success stories.

4. 3D printing is creating jobs in the US = TRUE!

Photo c/o www.sculpteo.com

Whether you like him or not, there is no arguing that President Obama is pumping hundreds of millions of dollars into improving and helping to spread manufacturing technologies such as 3D printing across the nation through several programs aimed at enhancing America’s technological capabilities.

Over the last year we have heard politicians, economists, and industry analysts all point their finger towards 3D printing as a means to bring manufacturing, and thus jobs, back to America from countries like China where we’ve been outsourcing a large portion of our manufacturing. Yes, 3D printing will eventually make manufacturing more affordable, but does that mean jobs will be created in the US, and that companies will bring much of the manufacturing process back to our soil? 3D printing will create many jobs for the America economy and in fact already has, as shown in our article on Sculpteo’s California Factory. We just don’t know if it will be the outsource-killer some economists and industry insiders claim.

At Sculpteo, it took us almost half a year to build our California 3D printing factory but now that we are fully operational we can ship prints in less time for less money. And we’re bringing on new employees as a result, so it’s undeniable that 3D printing is creating jobs in America! But it hasn’t shown to be a show stopper for outsourcing. We created our factory because there are many businesses looking to manufacture their own products/designs, and while it’s important to have these items created for as little money as possible it’s more important to create quality items. Speed and quality are extremely important to us and we felt strongly that having a factory in the US is the perfect solution. We were very excited and proud to open our factory doors and provide more jobs here in the US and we hope that you are excited and proud as well! You can also have peace of mind knowing that your products are made right here in USA!

5. 3D printing is dead = FICTION!

Photo c/o Sculpteo via www.pinshape.com

As is often the case with emerging technologies, the passage into a mainstream market is proving to be a slow and rocky one. The reason why AM is growing so slowly is because bigger, deeper-pocketed rivals like HP and Staples are making a belated but major push into the market, which may be giving customers pause. “Corporate buying managers are delaying purchases while they anticipate HP’s multi-jet fusion product in 2016,” Dougherty & Co. analyst Andrea James wrote recently. Balancing the short-term demands of investors with technologies that take a long time to mature predictably leads to slow growth. If things don’t turn around soon, some companies may be bought by a giant like GE. But just because the hype surrounding 3D printing got out of hand quickly doesn’t mean the technology itself isn’t promising. There’s still plenty of potential in the market longer-term. It will just take time to deliver on that potential. And meanwhile, speculative investors who are characteristically short on patience move on to the hottest new technology idea.

6. Additive manufacturing only for jewelry makers and artists = FICTION!

3D printing luxury watches: ALB & Sculpteo Photo c/o www.sculpteo.com

With its huge degree of design freedom, 3D Printing has introduced a new way of thinking about design. More than 50% of Sculpteo’s users identify themselves as Engineers, and roughly 30% identify themselves as entrepreneurs! We know that our services are used to create items in the medical field, robotics, and drone building (to name a few) creating jewelry with our service is done by less than 10% of our user base. Sculpteo’s users know how to build a design specifically for 3D Printing. If you truly want to get the most out of this technology, get us involved in your project in the design phase, and we can help you with design guideline info and money saving tools available on our site. We can help you whether you’re an inventor looking to create a first prototype or a company doing a short production run, choosing the right process for your needs is not difficult with our help. At the most general level, computer numerical control (CNC) machining, injection molding and 3D printing can all be used together for short runs and we can help you with the 3D printing side of your project. For example, stereolithography, selective laser sintering, CLIP, and DLP are all types of 3D printing, but each use different types of materials, and take different amounts of time.

As soon as you have your first 3D CAD, even if it hasn’t been checked for print-ability, we want to get that into our system and get you using out repair, review and optimization tools to prep your model for printing.

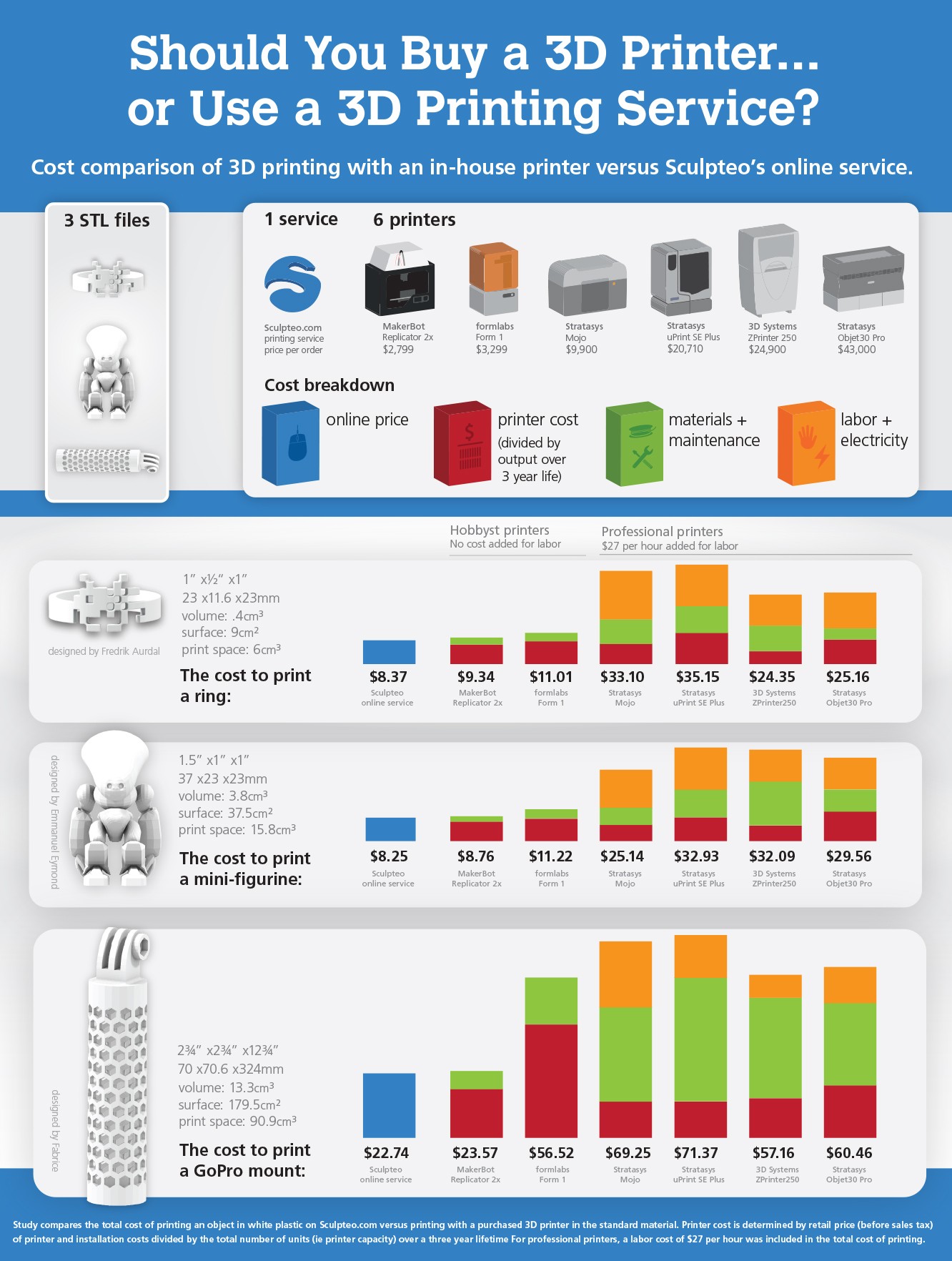

7. You do not have to buy a 3D printer to 3D print = TRUE!

Infographic “Should you buy a 3D printer or use a 3D printing service?” c/o www.sculpteo.com

You can still be part of the 3D printing industry, even without a 3D printer. One of the key concerns that arise in 3D printing purchasers is: “Am I willing to service and maintain my 3D printer, or would I just prefer to receive the 3D printed part?” Many people forget that they will be expected to know how to use, maintain, upgrade and provide maintenance to even the best models of 3D printers. And if you’re not sure if that’s what you’re interested in, then use a service! You will still need to understand how a 3D file works so you can make sure that your model is printable but there are tools that will help you along the way, such as solidity check and final proofing. So if you’re not the type of person who wants to tinker and get their hands dirty owning a 3D printer is probably not for you. Take a close look at our Infographic above and don’t forget to, sign up for the Sculpteo newsletter because next week we will publish an interactive page that will let you know if your better off buying a 3D printer or use a 3D printing service.

8. Plastic is not the only material for 3D printing = TRUE!

The materials available for 3D printing have come a long way since the early days of the technology. There is now a wide variety of different material types, that are supplied in different states (powder, filament, pellets, granules, resin etc). Specific materials are now generally developed for specific platforms performing dedicated applications (an example would be the dental sector) with material properties that more precisely suit the application. However, there are now way too many proprietary materials from the many different 3D printer vendors to cover them all here. Instead, this article will look at the most popular types of material in a more generic way. Sculpteo does not provide all of these materials but for the materials that we do offer you can click on the links to learn more about them.

Nylon, or Polyamide is commonly used in powder form with the sintering process. It is a strong, flexible and durable plastic material that has proved reliable for 3D printing. It is naturally white in color but it can be colored with dye post printing. This material can also be combined (in powder format) with powdered aluminium to produce another common 3D printing material for sintering — Alumide

A growing number of metals and metal composites are used for industrial grade 3D printing. Two of the most common are aluminium and cobalt derivatives. One of the strongest and therefore most commonly used metals for 3D printing is Stainless Steel in powder form for the sintering/melting/EBM processes. It is naturally silver, but can be plated with other materials to give a gold or bronze effect.

In the last couple of years Gold and Silver have been added to the range of metal materials that can be 3D printed directly, with obvious applications across the jewelry sector. These are both very strong materials and can be processed in powder form. Sculpteo uses the lost wax process to create items for our Silver users.

Titanium is one of the strongest possible metal materials and has been used for 3D printing industrial applications for some time. Supplied in powder form, it can be used for the sintering/melting/EBM processes.

Multicolor 3D prints leave the printer fully colored, using a fine powdered material that resembles sandstone. The sandstone material is painted and adhered during the printing process. As the material is painted during the process, the file uploaded to the sculpteo website must also contain the texture information. For more information, refer to our section about file formats. We are able to print in 390,000 different colors. Multicolor prints are thus the most rapid and economic way to arrive at a full colored object. Objects printed in multicolor can withstand temperatures of up to 60°C (140°F) – beyond that the object’s properties can be significantly altered. Multicolor objects are also somewhat fragile (comparable to a porcelaine), so it is important to handle them with caution. The prints have a gritty surface and are relatively porous. It is thus important to avoid direct contact with water as it could result in discoloration or running of the colors.

Paper: standard A4 copier paper is a 3D printing material employed by the proprietary SDL process. 3D printed models made with paper are safe, environmentally friendly, easily recyclable and require no post-processing.

Bio Materials: there is a huge amount of research being conducted into the potential of 3D printing bio materials for a host of medical (and other) applications. Living tissue is being investigated at a number of leading institutions with a view to developing applications that include printing human organs for transplant, as well as external tissues for replacement body parts.

Other research in this area is focused on developing food printing with meat being the prime example. Food experiments with extruders for 3D printing food substances has increased dramatically over the last couple of years. Chocolate is the most common at this point. There are also printers that work with sugar and some experiments with pasta and meat. Looking to the future, research is being undertaken, to utilize 3D printing technology to produce finely balanced whole meals.

Sculpteo’s PolyJet resin material creates 3D printed objects from a base of photosensitive polymer liquid. That liquid is then solidified by UV light layer by layer to create a rigid and highly detailed prints which are comparable to injection molded plastics. The final product has a naturally smooth surface which can be polished further to create near full transparency. Our resin 3D prints are originally either white or translucent. Sculpteo can then tint the object to a color of your choosing. You can also easily realize your own finishing with this material. You’ll find more information on at-home polishing in the paragraph on colors and finishings .

Flexible Plastic material developed exclusively for 3D printing; delivering a level of flexibility never before seen in the laser sintering 3D printing process. Exclusive to Sculpteo, this special material is a thermoplastic polyurethane (TPU) makes it possible to create functional objects with a Shore hardness level of 65A, and therefore to reproduce complex mechanical properties. It is now possible to 3D print a functional and truly soft object. Created using laser sintering technology, Flexible Plastic components combine freedom of design with a Shore hardness level of 65A, which is well below the market standard for 3D printing (the Shore hardness scale is used to measure the hardness/softness of elastomers).

9. 3D printing is optimized for large items like cars and homes = FICTION!

While there have been some products aimed at massive manufacturing, 3D printing is generally suitable for customized small run production. Maybe both categories will be covered by additive manufacturing technologies in the future, but for the time being, it seems that traditional manufacturing methods are here to stay and to produce massively at rates that are not achievable through 3D printing, construction falls under that category. This does not mean things won’t change, as some argue that on certain highly complex geometries (for example earring aids) it is already more convenient to 3D print up to 10,000 parts than to produce them with other methods. Also, 3D printing is starting to prove feasible but not optimized for manufacturing of objects as large as cars and houses. For more information about the use of 3D printing for construction and to see how Sculpteo helps architects create models for homes/buildings we’ve created a page on our site and a blog post dedicated to this topic.

10. Everyone will have a 3D printer in the house = FICTION!

Three-dimensional printing relies on various CAD software (the standard application in architecture, industrial design and, now, 3D printing to design files that printers use as blueprints to build from. So if the average consumer wanted to design something to print in 3D, he or she should have a working knowledge of CAD (in some cases). While there are online 3D file marketplaces, many of the files tend to be flawed, with pieces that don’t quite fit as expected, and often still need to be edited in CAD or on the Sculpteo website. It’s because of this, 3D printing is unlikely to be present in every home. We do see that there a rise in younger kids learning CAD and this could close a gap in the distant future. But for now a printer for every home is definitely fiction.

11. It is expensive to make things with additive manufacturing = FICTION!

Photo c/o www.sculpteo.com

If you’re interested in 3D printing, you have a few options. First, you can head to your local makerspace and become a member, many of them have open-house days so you can stop in and see the facilities before you pay to become a member. If makerspaces around you do not have access to a 3D printer a more practical approach is to use a service such as Sculpteo. We will take your model, and then 3D print the final object for you so you don’t need to invest the time and money into a printer. If you’re not familiar with 3D modeling there are market places online where you can download a model (sometimes for free) to upload to a servicer and receive your 3D print in the mail. If you can manufacture useful (and customized) things for the home instead of being made to wait for a large company to create something that’s not quite what you want, why wouldn’t you want to use a service? Sculpteo’s optimization tools can help you save money as well.

12. 3D printing won’t replace other forms of manufacturing = TRUE!

Photo c/o www.sculpteo.com

Advances and improvements in 3D printing have raised the technology’s profile as a game-changer in manufacturing over the last several years. While rapid prototyping and the additive manufacturing methods that 3D printing comprises have been around in some form for decades, the greater accessibility, affordability and versatility that today’s 3D printing offers mean that its potential to change manufacturing as a whole is at an all-time high. Yet will 3D printing ever completely replace traditional manufacturing? Will other methods like CNC machining eventually be supplanted by the possibilities that 3D printing offers? Our answer to that is no.

Althought 3D printing has it’s benefits, consider creating complex mechanical constructions via traditional manufacturing. It has always been a difficult, multi-step, and expensive process requiring a great amount of precision and skill — even for computer-controlled manufacturing. When tolerances are off even by a few hundredths of an inch (or smaller), it can mean an ineffective part — and lost time, resources, and money for both the manufacturer and the customer. What’s more, assembly of these complex parts is a battle of accuracy and access (in that the area in question to be assembled must be reachable by person or machine). 3D printing solves those problems by creating an entire piece in one process through additive manufacturing, simply building a part to spec layer by layer, instead of creating each component and then assembling and finishing the completed product. But this process is here to stay and the reason is, for mass manufacturing the traditional process is more cost effective. But when utilizing traditional manufacturing for small batch runs, or mass customization runs we see that 3D printing comes out as the clear winner. In short, the greatest potential for 3D printing lies not in replacing traditional manufacturing, but in supplementing it and improving the potential for better overall products. By understanding the benefits and drawbacks of all of the processes available, innovators, product designers and manufacturers will be better able to facilitate advances in their respective fields. While traditional processes aren’t going anywhere, they can be used with greater efficiency — for the processes and projects for which they’re suited best — while efficiencies found in other processes like 3D printing will help lead to a better overall process and product.

We hope you’ve enjoyed our list of 12 Additive Manfuacturing Truths and Fiction!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook