Is your 3D file good enough for 3D Printing? 6 questions to find the answer

Posted By Nicolas Sadeghi on Jun 1, 2016 | 0 comments

Here at Sculpteo, we encounter a lot of different 3D files. However, some of them are not suitable for 3D printing, and need some more work before being produced. Here are the 6 questions you should ask yourself whenever you want to launch the printing of an object!

Does your 3D design have volume?

First of all, you need to be sure that your design is a volume. Try to imagine a flat surface as an object: if it exists in real life, it necessarily has at least some thickness. On your computer, be sure that you have this minimal thickness everywhere, in order to avoid trying to print the impossible. To prepare a model for 3D printing, you must first give volume to your surfaces, for example by extruding them.

To find the right information about the layer thickness that’s right for your file, you first need to refer to the correct material you’re going to use. You’ll find that information on our dedicated material pages for 3D printing.

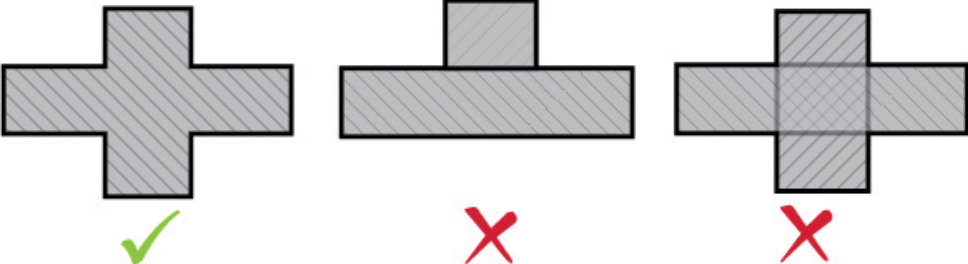

Does your design have inner intersections?

While you design your model, you will sometimes make two or more volumes intersect each other. These intersections create an ambiguous model with uninterpretable parts. Indeed, the computer doesn’t understand that both volumes are to be combined, and thus fuse them, creating an anomaly. The functions that can merge these elements to solve this problem are called Boolean operations. They help you unify, subtract or differentiate volumes, in order to keep only “one” volume everywhere.

Is your design watertight?

One of the most common issue for 3D printing is whether or not your model is watertight. This means that your model has to be closed. All edges need to be connected to one another. There can be no edges or vertices that do not create a closed surface because it will have no thickness for 3D printing. You can, however, overlap geometry as long as all the surfaces are closed.

An easy example to understand this concept is to imagine that the inside of the volume is filled with water and none of it must be able to come out of it.

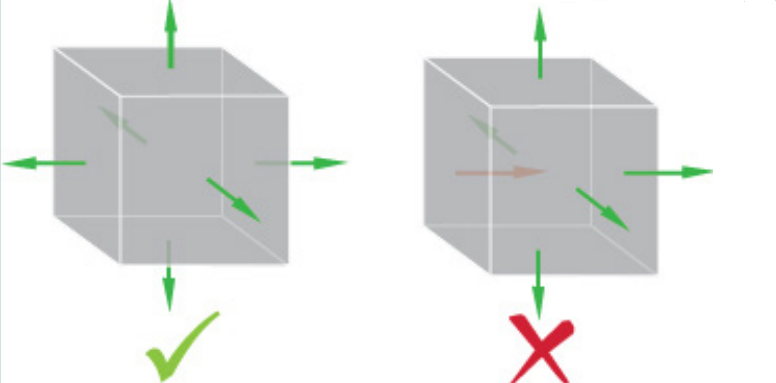

Are your surfaces correctly oriented?

In most 3D modeling software, surfaces are oriented with an inside and an outside to help determine the model’s volume. If one of the faces of an object is oriented in the wrong direction, its volume may be difficult to evaluate. It is important to ensure that each face is oriented in the correct direction in order to avoid this type of problem.

Will your object be solid?

A 3D model that looks great on the computer screen will sometimes not look the same when printed. To avoid this, you must adhere to the minimum requirements for the specific 3D printing process you chose to use. For example, 3D models that have really thin features could break, especially if those thin areas were to support large or heavier surfaces.

We said earlier that every 3D model needs some thickness to be 3D printed. This parameter has a minimum value, that depends on which material you decided to use for your model. By abiding by this minimum wall thickness, you can avoid unnecessary breakage and avoid printer errors when trying to 3D print. It will affect the small parts of your projects, such as columns, wires, cables or doors.

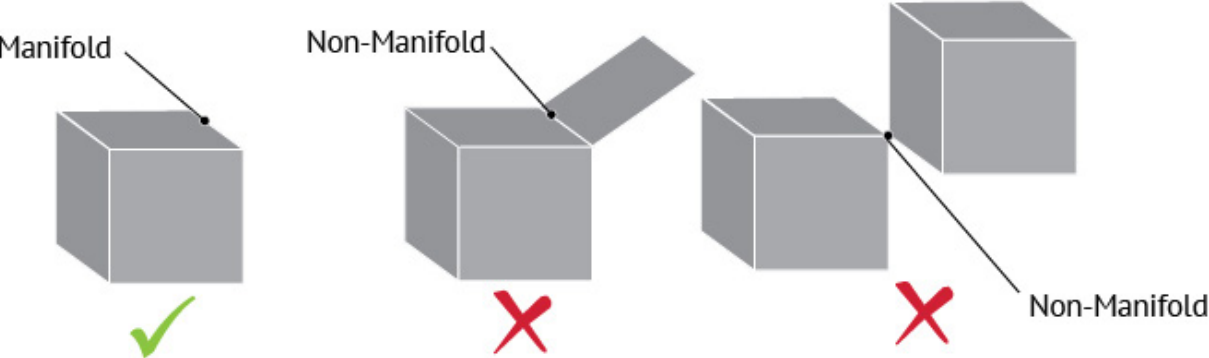

Is your file “two manifold”?

It may occur that while you work on your design, certain operations create unattached, ambiguous surfaces which do not connect to each other. You could also separate by inadvertence your model, only keeping it together by a single point. These singularities may be the cause of some problems as the volume won’t be recognized as such, thus making the model unprintable. To define a clear volume, each edge must be connected to two and only two adjacent faces. Similarly, singular points must arrive at the collection of multiple faces. If two or more faces, in different volumes,have only a single point in common, the model is considered “non-manifold” and will not be able to be 3D printed. To solve this problem, try to separate the two parts, and make the non-manifold part a volume.

Those are the most important advice we would give you to create a proper 3D file for 3D printing.

Once your model is clean, you may look at the operations you could do to get a better quality, or lower the price of your printing. You can, for example, hollow your model, to remove the volume’s insides. The price will drop significantly while the outside rendering will remain the same. You can also optimize the number of triangles, to reduce the size of the file or even to smooth the surface of your model.

Feel free to look at our different tools, they may provide you the final touch you need to make your design a true masterpiece!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook