Take the assembly out of your enclosures by designing a living hinge

Posted By Jess Hedstrom on Jun 1, 2016 | 0 comments

Assembling your enclosures take time and effort to complete, and the last thing you want to do is hand assemble 3D printed enclosures if you don’t have to. That’s why today we will show you one unique design for hinges that will remove the assembly step.

Integrated assembly is only one of the many benefits you receive when you use additive manufacturing to create your parts. This is a big benefit for those interested in saving not only time but also money. Assembly can be very time and labor intense; in an effort to decrease your time and money on assembly for your enclosures, we have taken time today to create a list of unique enclosure designs that will remove assembly altogether.

Introducing the functional hinge:

- What is it?

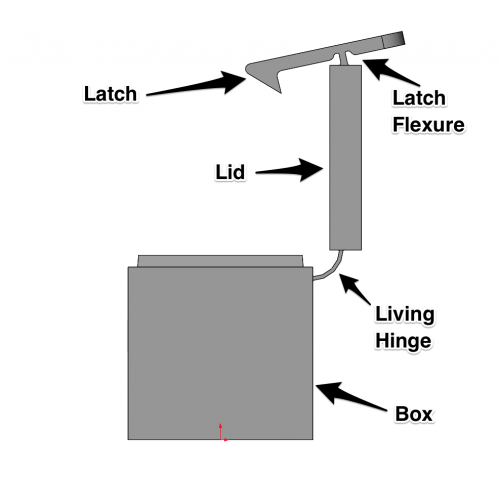

The “living hinge” is the most common functional hinge design that engineers will agree is the easiest to design, this hinge can be described as a thin, flexible hinge, made from the same material as the two pieces it connects. This design style allows for enclosures that do not require any assembly. As soon as they are taken from the print bed the piece can be manipulated.

Functional Hinges: https://markforged.com/mmf-living-hinges-3d-printed-part/

Photo provided by Markforged

What kind of materials are great for this type of hinge?

- FPU, Prototyping Resin, Plastic, and TPU

The best materials for creating living hinges are flexible materials like our Flexible Polyurethane, FPU and TPU; by designing with a flexible material in mind you’re able to create a living hinge that can meet most design guidelines. The hinge which is the most thin part of the design does not need to be extremely thin when working with a flexible material.

Even when working with less flexible materials it helps to design for the material and the technology you will be using so that you will be aware if supports are needed. In the event that supports are needed be sure to put the supports in an area that will not affect the living hinge’s ability to flex. *When working with Prototyping Resin and our Flexible Polyurethane supports are needed.

Photo provided by Carbon

What’s the durability of living hinges, do they last longer or require any upkeep?

- Durability of living hinges

Durability of your living hinges depend on the type of material that you have chosen. You can always print and test the living hinge to make sure that you know the flexibility tolerances for your object. That way you’re able to inform your customers.

Are living hinges only available with additive manufacturing? If not why should I use 3D printing for my living hinge?

- 3D printing for living hinges

When working with additive manufacturing for your living hinge you’re able to create more complex designs and integrate the assembly process into your design. Which saves time and money in the long run. There are also specific guidelines specific to each material which will help remove any need to adhere to wall thickness and clearance guidelines when designing a multi-piece part that needs to be assembled after printing. Also no gates necessary when designing for 3D printing (unlike designing for injection molding).

Photo provided by Markforge

What’s better than a living hinge

- Why are living hinges better for your project than other options for hinges?

Living hinges are the best option because they never need upkeep or repairs. They either work or they don’t, and generally based on your material they can be created to have up to a specific amount of bends before wearing out. Also the range of motion is better with a living hinge than when using a pin and hinge design.

We hope that your questions have been answered regarding living hinges for your enclosures that do not require assembly. While there are many different ways to create hinges, and there are many materials to select from you can see that living hinges are not the only hinge option but they are a great option when paired with additive manufacturing.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook