3D Printing with Prototyping Acrylate: the complete Q&A

Posted By Hannah Bensoussan on Jul 6, 2016 | 0 comments

Over the past 10 weeks, we’ve had the opportunity to use the new Carbon3D M1 digital light projector (DLP) resin-based 3D printer. Not only is the M1 printer the fastest in its category (stereolithography (SLA) printers), it also is compatible with a wide range of materials. In this blog series, we will share our expertise on the Carbon 3D M1 resins. After the 1st post on Rigid Polyurethane and the second article on Cyanate Ester, this article will focus on Carbon’s resin with the most general applications: Prototyping Acrylate.

What does the Prototyping Acrylate look like?

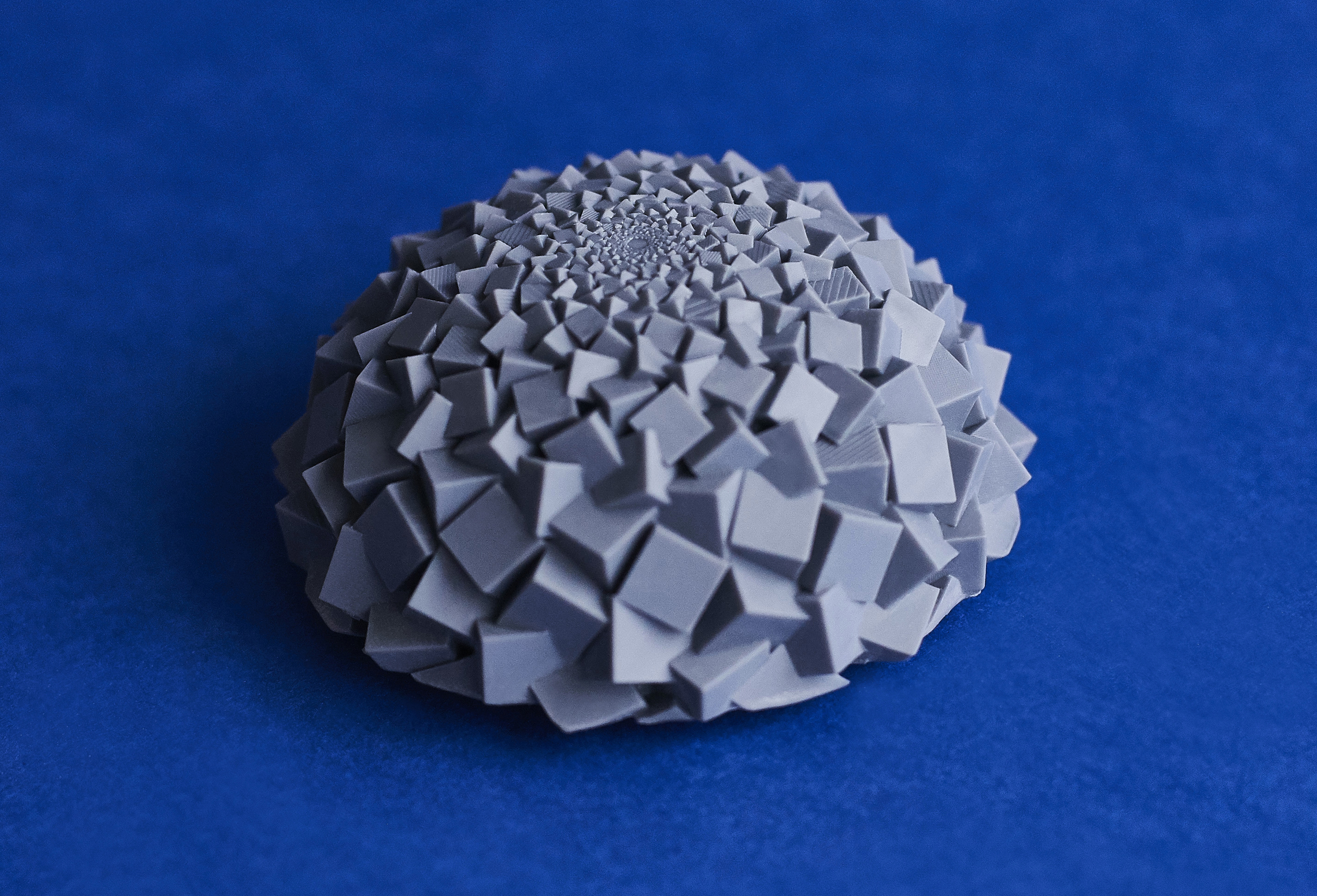

General Purpose Prototyping Acrylate is the only material offered by Carbon that comes in more than one color, in fact the prototyping resin comes in 6 colors (cyan, magenta, yellow, grey, black, and white) which can be mixed to create custom colors, this is only offered on demand and for bulk orders. This material is shiny before it is cured, after curing the colors remain vibrant but the surface becomes matte. The surface is less smooth than a Polyjet for example. This is a rapid production resin you can use to quickly try out designs and make parts with remarkable detail. Depending on the orientation of the model when you are 3D printing, you can occasionally see very thin layers that are not strictly speaking machine layers. These are instead more artifacts coming from the process and do not cause fragility to the part.

How precise is the Prototyping Acrylate for 3D printing?

The M1 3D Printer can print at very high resolution. Features as thin as 0.25 mm can be 3D printed, but the recommended thickness for certain structural features will vary based on their specific nature. For example, a vertical wall 5 cm in height will be somewhat flexible if it is printed at a thickness of 0.25 mm, but rigid if it is printed at a thickness of 0.4 mm.

What kind of 3D printed parts is the Prototyping Acrylate good for?

Prototyping Acrylate parts are much more like injection-molded parts than objects produced with other 3D printing techniques. CLIP produces consistent and predictable mechanical properties, creating parts that are smooth on the outside and solid on the inside. Prototyping Acrylate is similar to SLA resins. It creates objects which are smooth and precise. This resin is perfect for ornamental objects, and proof of concept prototypes. They can also be used for more mechanical uses (considering that the part is not under repeated stress).

Can I print moving parts with the Prototyping Acrylate?

In theory, you could, but it really depends on your 3D model. Prototyping Acrylate, as with any CLIP resin needs to be supported during the prints. That means that we need to support any moving parts and depending on the geometry it can be very difficult to remove the supports. We have printed the Sculpteo logo for instance without any problem, but the clearance is tremendous. It’s too early for us to know what is the perfect minimum clearance requested that’s why we don’t offer interlocking parts option on any CLIP resin so far.

How does the 3D printer work?

When you upload your 3D file on Sculpteo.com, we take care of your file by repairing it if needed and preparing it for the selected 3D printer. The M1 3D Printing is using CLIP technology. CLIP, which stands for Continuous Liquid Interface Production, eliminates shortcomings of other 3D printing technology by emphasizing a tunable photochemical process over a traditional mechanical approach. Regarding Prototyping Acrylate, this resin allows for speedy prototyping with better than average resolution, which is owed in part to the quick open and pour nature of the Prototyping Acrylate.

How should I prepare my file for a 3D print in Prototyping Acrylate?

3D models can be prepared similarly as for SLS printers, with one exception. If a design has an enclosed hollow region, the liquid resin will be permanently trapped within the cavity. To avoid this, designs for the M1 3D printer should include an opening to allow drainage of the excess uncured resin from hollow regions. As with other DLP 3D printers, the M1 printer will create supports for overhang regions that will be removed later. For efficient support removal during part cleanup, try to design your part such that areas that need support are accessible!

What kind of finishing can I get?

We offer 2 types of finishing for Rigid Polyurethane on the website

- Raw : we cut the supports

- Hand polished: we manually sand and polish the part in order to remove any support scars.

The CLIP resins are still in a testing phase, but we will release them really soon. If you would like to 3D print in Prototyping Acrylate you need to register to the CLIP Pilot Program. We explain you everything here. If you have any other question regarding Prototyping Acrylate and CLIP technology, don’t hesitate to contact us.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook