Made in France or Made in the USA: Where are your parts produced?

Posted By Jess Hedstrom on Jul 27, 2016 | 0 comments

Manufacturing locally has many benefits, almost as many benefits as using 3D printing to create customized parts. Today we explore the benefits of producing your parts locally, and we take a deep look at what is produced in the US factory vs. what is produced in our French factory.

Made in the USA or Made in France: What are the benefits to buying local?

Manufacturing is critically important to the economy of any nation, and for hundreds of years, the strength of many countries relied on the products that come out of their factories. All countries need manufacturing if they want to build a strong economy for years to come, and as you will discover, customers receive immediate benefits when purchasing from local manufacturers. For example, at Sculpteo if you are in the US and you order a part that is produced by our US factory, your lead time will be decreased. The same is true if you are in France and order from our French factory. That means less time for you to wait, which can remove bottlenecks in your product / iteration flow.

One of the biggest problems with buying imported goods is that import is one of the biggest contributors to pollution. You’re reducing your carbon footprint by purchasing locally and when you buy local you are actually reducing the amount of pollution in your area. And when you buy local you’re helping to boost your local economy! By deciding to purchase locally you’re are able to recirculate your money into your local economy, which can lead to more jobs.

Made in The USA

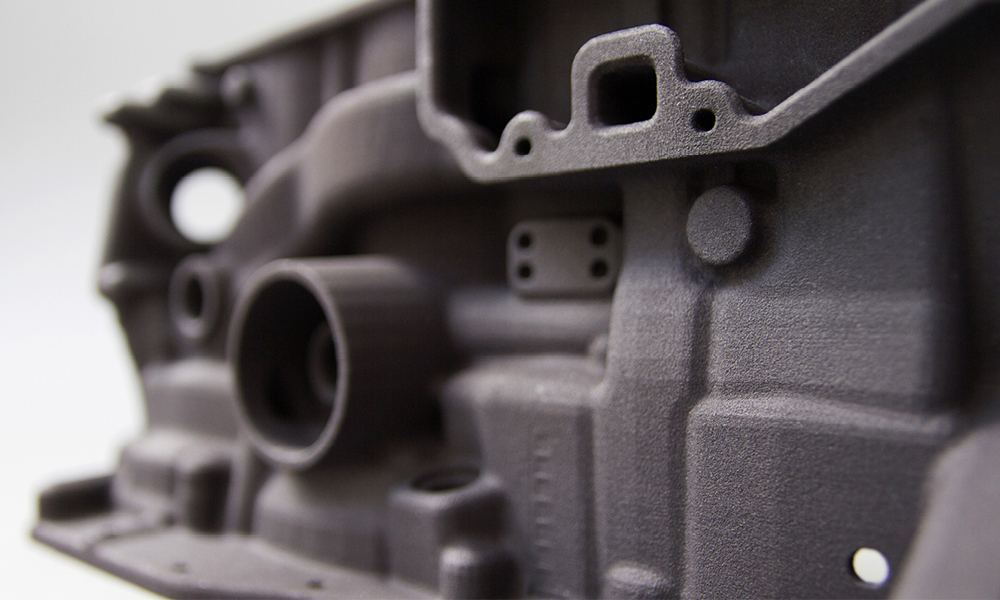

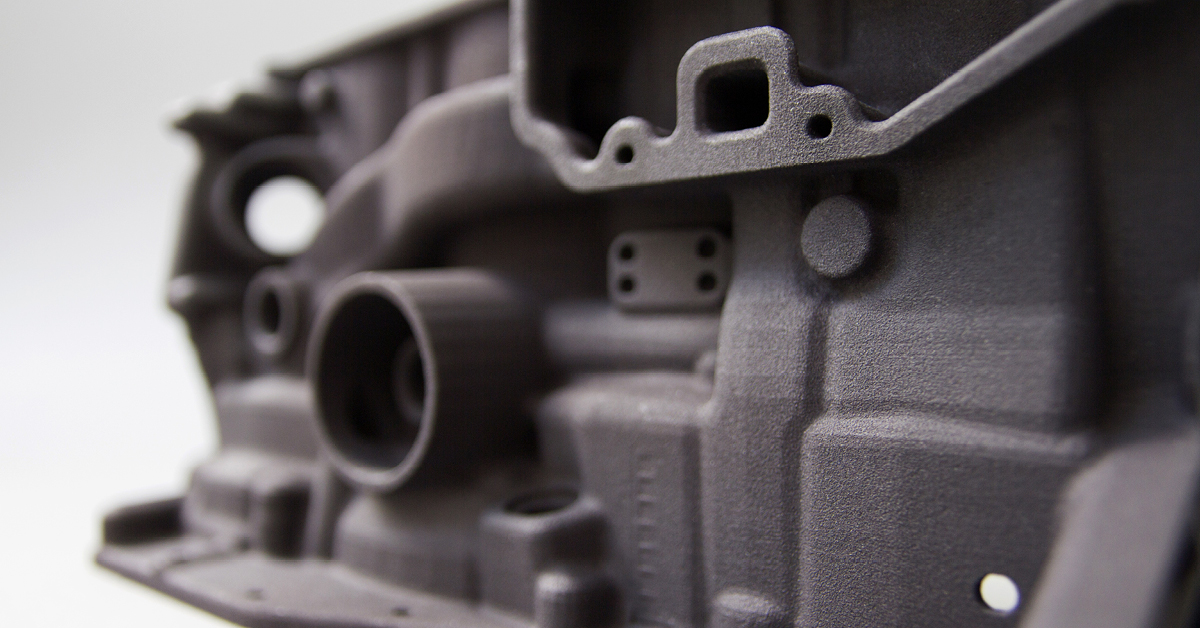

Our most popular material: Polyamide

In our USA factory we process our white plastic material, which is a nylon based polyamide (PA 12), simply put this material is optimized for use as a laser-sintering material. Laser-sintered parts made from this material are characterized by high impact resistance and elongation at break. Plastic is our most popular material due to it’s low cost and durability. The material is based on renewable resources and can therefore be classified as environmentally friendly material. We provide this material in 100μm from our US factory, and we can have it polished and dyed. If you want 60μm, or if you want your PA part to smoothed using our smoothing beautifier technique, this will be processed in our French factory.

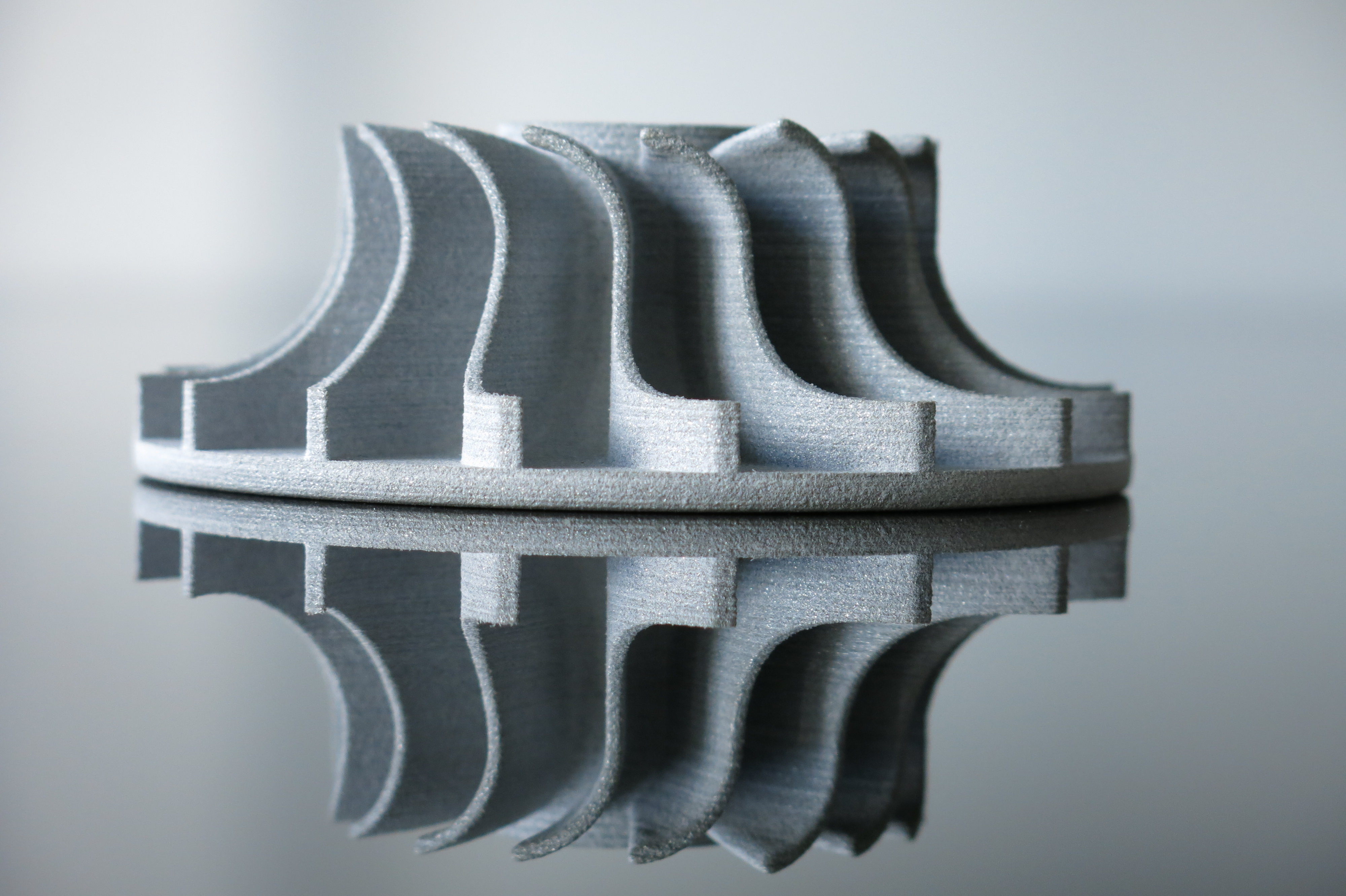

For a great resolution: our CLIP resins

If you are interested in resin, our CLIP resin options are available for you through our US factory. The resin liquid is solidified by UV light layer by layer to create your rigid and highly detailed prints. In most cases, the end results are comparable to injection molded plastics. The final product has a naturally smooth surface which can be polished further to create near full transparency. It has great resolution. Learn more about the four CLIP resins we offer: Cyanate Ester, Rigid Polyurethane, Prototyping Acrylate, Flexible Polyurethane and Elastomeric Polyurethane. Flexible Polyurethane and Elastomeric Polyurethane are still in their Pilot phase.

Made in France

White, black, grey polyamide

As stated above white powder polyamide (PA 12), that can be polished or dyed, is produced in both our France and US factories, with added options in our French location (smoothing beautifier, 60μm resolution). Your pricing and delivery will reflect those modifications instantly when you select those options. As for polyamide produced in France, we also have grey plastic and black plastic (PA 11).

Multicolor materials

The factory in France also processes Full Color Sandstone parts typically used for artistic pieces and figurines. We are able to print in 390,000 different colors. Multicolored prints are thus the fastest way to arrive at a full colored object.

Laser cutting

And of course, in our French factory, we offer, now in beta, the option of laser cutting brand new materials. Discover our beta offer, and our material options: cardboard, MDF, plywood and acrylic with more than 60 options of thicknesses and colors.

We hope that this will help you make informed purchases as you discover the possibilities with Sculpteo’s services.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook