Laser Cutting Stories: What Our Team Created #1

Posted By Capucine Lonjon on Sep 21, 2016 | 0 comments

It’s been two weeks since our laser cutting service went out of Beta. We are very happy to see that orders keep on coming !

In the same time, we are constantly improving our service. We’re adapting our material offer, we’re experimenting to have more precise design advice, and our designers are examining insightful means to combine laser cutting and 3D printing.

A creative and resourceful team

At Sculpteo, we are proud to have such a creative team. During off-peak hours, relaxation break, or their personal time, members of each of the departments have tested our new laser cutting service. Most of them discovered this technology and they went along with it very quickly. Today, they’re giving you their experience. They explained how the service we implemented works, particularly the interactive tools of our platform, and how it accelerated their learning of the technology.

Read the other stories!

Laser Cutting Stories: what our team created #2

Laser Cutting Stories: what our team created #3

Today, Nora Toure – our Business Development Director, Alex Gryson – our UX designer and Katy Nguyen – one of our technician, speak about a creative hobby project they conceived thanks to laser cutting.

‘A very easy tool to get into laser cutting’ – Nora, Business Development Director

S: What’s your favourite feature of Sculpteo’s laser cutting service?

N.T: I’d never used a laser cutting machine before and never even thought about it until we decided at Sculpteo that it was a service we wanted to add into our portfolio for our customers.

When I was asked to test out our beta service a few months ago, I was surprised at how straightforward and easy the process was. What I personally liked at first was the simplicity of the tools. I was expecting something very complex to use and actually got to be used to the process to be easier!

S: How has the service helped you with your project?

N.T: I used laser cutting to create a Nespresso capsules holder.

We got a Nespresso machine for Christmas and I was looking for a nice capsule holder as I currently just stack them in a drawer. I’m used to having little 3D printed robots all around my house and thought it would be great to now have something that is laser cut. That’s how I came to the idea of laser cutting a capsules holder!

S: What are the advantages for you of an online platform like ours?

N.T: From my personal experience, it allows people like me, who never experienced laser cutting before, to get into it easily and stress-free.

From my professional point of view, as the Bus. Dev Director in our San Leandro location, I see my customers using it as a complementary manufacturing tool, and they enjoy the straightforward online platform of Sculpteo.

They have been using our platform for their 3D Printing needs for years, and they are happy to now have the option to order laser cutting from the same place. Once they’ve set up a vendor in their system, they are happy to have a single place to process most of their Digital Manufacturing needs in a matter of a few days.

S: Have you thought of any hybrid projects, that mix laser cutting and 3D Printing?

N.T: I love world maps. Would be fun to have a laser cut wood map with placeholders for the major attraction of each country.

Imagine a laser cut map of France with a mini 3D Printed Eiffel Tower coming straight out of it!

S: Any tips for our customers?

N.T: Should you have any question about our awesome new service, please let me know! Have fun!

‘Saving time and effort for my RPG terrain pieces’ – Alex, UX designer

Sculpteo: In a few words, could you present your project?

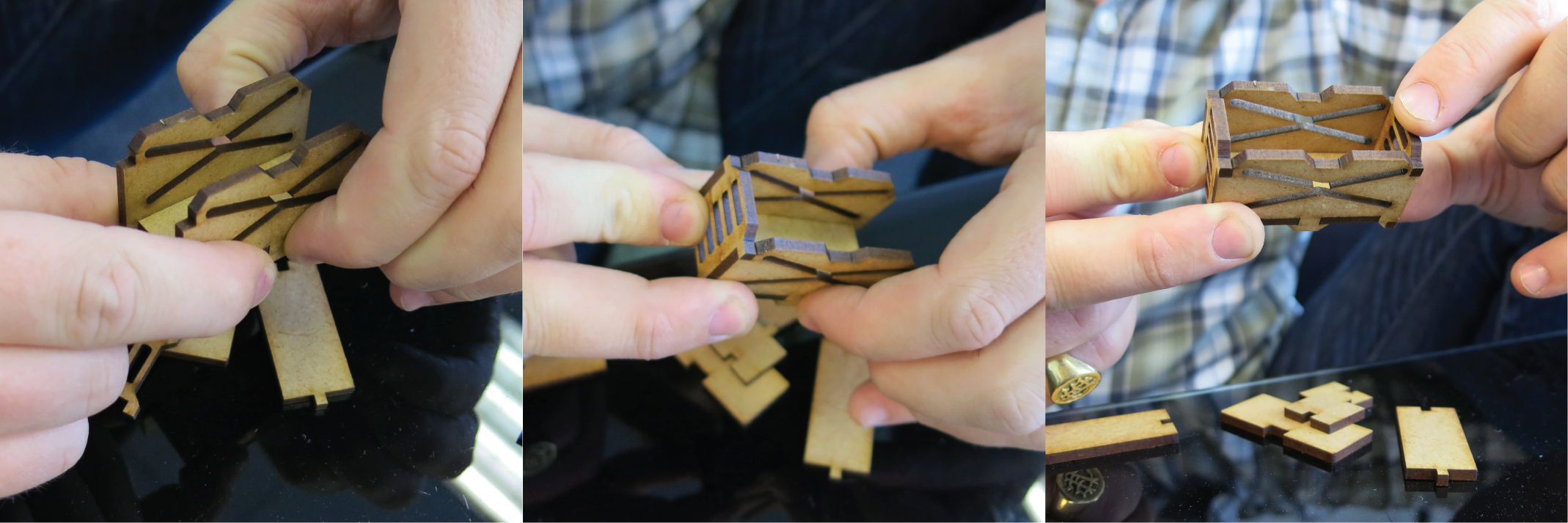

Alex Gryson: So these are terrain pieces for tabletop RPG’s. Almost all of it has been cut in 3mm MDF, though I used 1mm Card to make the stencils needed for the details on the containers and the skip/dumpster. Every week or two, I’ll sketch out and design a piece and have it cut. Then I do the gluing and painting to make it fit into my campaigns. I don’t use Engraving that much since a big part of the hobby for me is the painting and modelling, which is why I used stencils instead of just engraving it on.

S: For how long have you been thinking of developing this project?

A.G.: Honestly, I hadn’t planned on it at all! I used to do tabletop wargaming when I was a teenager (even then, I lived out in the Irish countryside so it was more about painting and modelling than actually playing). When I learned that we [Sculpteo] were going to start laser cutting, I thought I’d cut a few pieces just to get a feel for the technology, its limitations, quirks and things like that. The original idea was to get a feel for what our users needed from the interface (I’m the UX designer at Sculpteo) but I quickly got hooked and after laser cutting a few designs by other people like a dice tower and stuff, I started making my own designs. I’ve got maybe half a dozen pieces now and add a new one every month or so.

S: What’s your favourite feature of Sculpteo’s laser cutting service?

A.G.: The configuration panel. It lets me upload a terrain design with lots of different details. This lets me try different configurations out without having to go back to the drawing board every 15 minutes. If, in the end, a particular detail doesn’t suit me, I just set it to “None” and the price updates automatically. For example, I’ll often add just a few little engraved details to my pieces and check the price with or without them.

S: How has the service helped you with your project?

A.G.: Factory pickup lets me very quickly iterate on designs, test them that evening and recut until I finalize the design, at which point I add it to my stack of final designs in my objects library. That way I have all my versions in one place, with materials and scale already set. Getting from an initial design to a final piece often take only a single week.

S: What are the advantages for you of an online platform like ours?

A.G.: If I were renting time at a maker space or anything, I’d be forced to try to optimize my laser time. This would cost me a huge amount of time and effort to make sure my files make the best use of the laser. That’s perfect if I’m working on a product that will be scaled up, or if I’m already in the maker space for other projects on a regular basis. But given that this is my hobby, the amount of time I want to waste on stuff like that is minimal!

Going through a service like Sculpteo means that those optimization worries are offloaded and I can focus on what I want to do – designing cool terrain pieces, not wrestling with vectors.

This also applies to other laser cut services who force you to use a template of fixed size – I would always be afraid of wasting material if I didn’t quite fill that template. Sculpteo’s service lets me just get what I want. It’s the closest thing to having my own laser cutter.

S: Have you thought of any hybrid projects, that mix laser cutting and 3D Printing?

A.G.: Yeah, I mainly laser cut for the bigger pieces of tabletop RPG terrain. The simplicity and cost benefits of laser cutting are great, but 3D printing can give you much richer detail, especially for smaller, repetitive pieces. By using the two in tandem, I can get terrain pieces of incredible detail with the best fit of complexity to cost. I 3D print all of my model bases for example to get a nice decking effect.

S: Any tips for our customers?

A.G.: Make sure there’s an element of known size in your design, even if it’s a square that you’ll set to “None” before cutting. That way in the review section, you can confirm that scales are perfect, or update them, before continuing.

‘Easy assimilation thanks to an intuitive platform’ – Katy, Finishes, and Post-process Technician

Sculpteo: In a few words, could you present your project? For how long have you been thinking of developing this project?

Katy Nguyen : I really like puzzles and Chinese boxes. I find it a stimulating challenge and I could stay hours almost hypnotised! When I learnt we were launching a laser cutting service, I absolutely wanted to cut my own object to try the system. At Sculpteo, I work as a Finishes and Post-process Technician : I’m in charge of all finishes, such as painting for 3D printed objects. I am therefore always looking for new supports to paint. I thought wood would be interesting for me to treat. I went on Thingiverse, looking for a beautiful puzzle I could cut in wood. I found a puzzle from Pentominos, each piece representing a zodiac animal. I am very familiar with those Chinese animals and believes. I am very happy with the result.

S: What’s your favourite feature of Sculpteo’s laser cutting service?

K.N.: The possibility to upload your own file and have an interactive quote in only a few seconds. It is amazing! The choice of materials is also very pleasing. For now, I’ve worked with plywood. But I also would like to try acrylic and cardboard!

S: How has the service helped you with your project?

K.N.: At first, I wanted to test how the service works. The colors I can choose on the platform to select engraving/cutting eased my upload, they are very convenient. Once I had chosen the shape for my puzzle, I only had to upload it on Sculpteo’s website, and then I received the parts very quickly.

S: What are the advantages for you of an online platform like ours?

K.N.: Easy accessibility ! Even though I am a beginner in using laser cutting technology, I could very easily upload my file. Receiving the puzzle all cut in a few days is so accommodating!

S: Have you thought of any hybrid projects, that mix laser cutting and 3D Printing?

K.N.: Not yet, but I should think of it!

S: Any tips for our customers?

K.N.: I would advise they read very consciously our design guidelines on our material pages to truly understand what will be the final result! As for me, I had no negative surprise, fortunately ! But if you’re designing yourself your 2D file, it’s better to hold the keys for the best design.

To go further!

Onshape, Illustrator, Sketchup, Inkscape, are so many software that Sculpteo’s members used to create those beautiful projects. Visit all our tutorials here!

Continue the series!

Laser Cutting Stories: what our team created #2

Laser Cutting Stories: what our team created #3

Did you like this article? Share it on Facebook, Twitter and LinkedIn!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook