3D Print in EPU: a new CLIP Resin Available for All

Posted By Eole Recrosio on Nov 2, 2016 | 1 comment

After releasing Rigid Polyurethane (RPU), the next CLIP material to go out of our Pilot Program is the expected Elastomeric Polyurethane CLIP Resin (EPU). After uploading your design on our website, you can now choose, directly from the list of materials, the CLIP EPU Material and start 3D printing your stretchable object.

When Carbon released its CLIP array of materials, we were very excited here at Sculpteo to show you that whole new range of possibilities with these new resins. We first launched our Pilot Program in beta testing, where it was available for users who could explain a specific project, before progressively making it accessible for everyone.

That day finally arrived and you can now choose the CLIP Carbon EPU Resin!

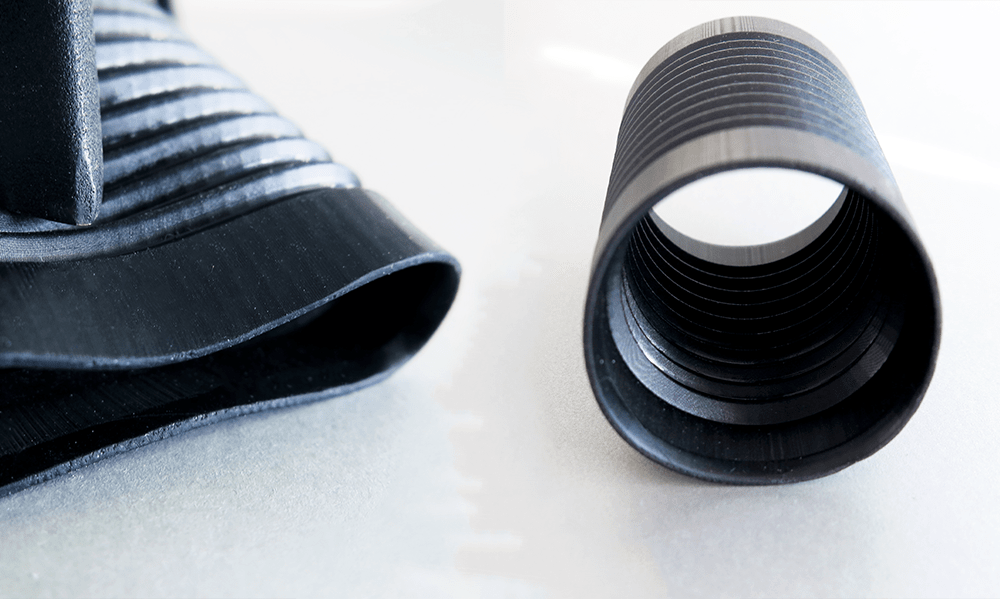

The 3D printed object is extremely strong and flexible, and will automatically take back its original shape

CLIP (Continuous Liquid Interface Production) technology, thanks to its continuous 3D printing process, allows us to print with a layer thickness of 100 µm or 0.1 mm which are almost invisible. Parts are then very close to injection molded models, which makes it very interesting for prototyping.

Choosing EPU resin instead of injection molding for your prototype brings a lot of advantages:

| Injection molding | EPU Resin |

| Can cost from 1 000$ to 80 000$ just for the mold | Less material used and no mold needed |

| Attractive for only big series of models | profitable for small series of model from the first one printed |

| Mold making time takes about 3 weeks | No mold needed so the printing process start earlier and is faster than many other techniques such as FDM |

| Complex shapes need complex molds and a higher chance of breaking | Complex shapes are especially designed for 3D printing |

Elastomeric Polyurethane CLIP Resin, due to its high performance allows excellent elastic behavior under cyclic tensile and compressive loads. You can stretch it and bend it, it takes back its original printed shape.

The material is especially designed for gaskets, grommets, and flexible watertight seals. EPU resin is rubbery, resistant, flexible and stretchable.

You can find more informations and guidelines on the CLIP EPU Resin page.

The M1 CARBON 3D Machine can also print 3 other materials, that we are keeping for now in our BETA Program. You will find the technical and design specificities on our website:

- Flexible Polyurethane CLIP Resin (FPU) is robust and resistant to impacts

- Prototyping Acrylate CLIP Resin (PR) is available in 6 different colors

- Cyanate Ester CLIP Resin (CE) has a high resistance to temperature, is very solid and rigid

If you feel interested by Carbon CLIP technologies, you can subscribe to our newsletter and be told when a new material is released.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook