Laser Cutting Stories: What Our Team Created #3

Posted By Capucine Lonjon on Nov 16, 2016 | 0 comments

Here is the third series of our employees’ creations in laser cutting. Our laser cutting service is now running well and two of our employees are pleased to share their project with you! Our team members are very enthusiastic users of our services.

They explain how the service we implemented works, particularly the interactive tools of our platform, and how it accelerated their learning of the technology.

Read the other stories!

Laser Cutting Stories: what our team created #1

Laser Cutting Stories: what our team created #2

Today, Hannah Bensoussan, content marketing manager and Charles Desjonqueres, API Project Manager tell you tips and their experience of our laser cutting service, through the creation of a Goban (a board for the Chinese-Japanese game Go) and colorful glasses.

‘My tip is to turn to the Internet for tips!’

– Hannah, Content Marketing Manager

Sculpteo: In a few words, could you present your project?

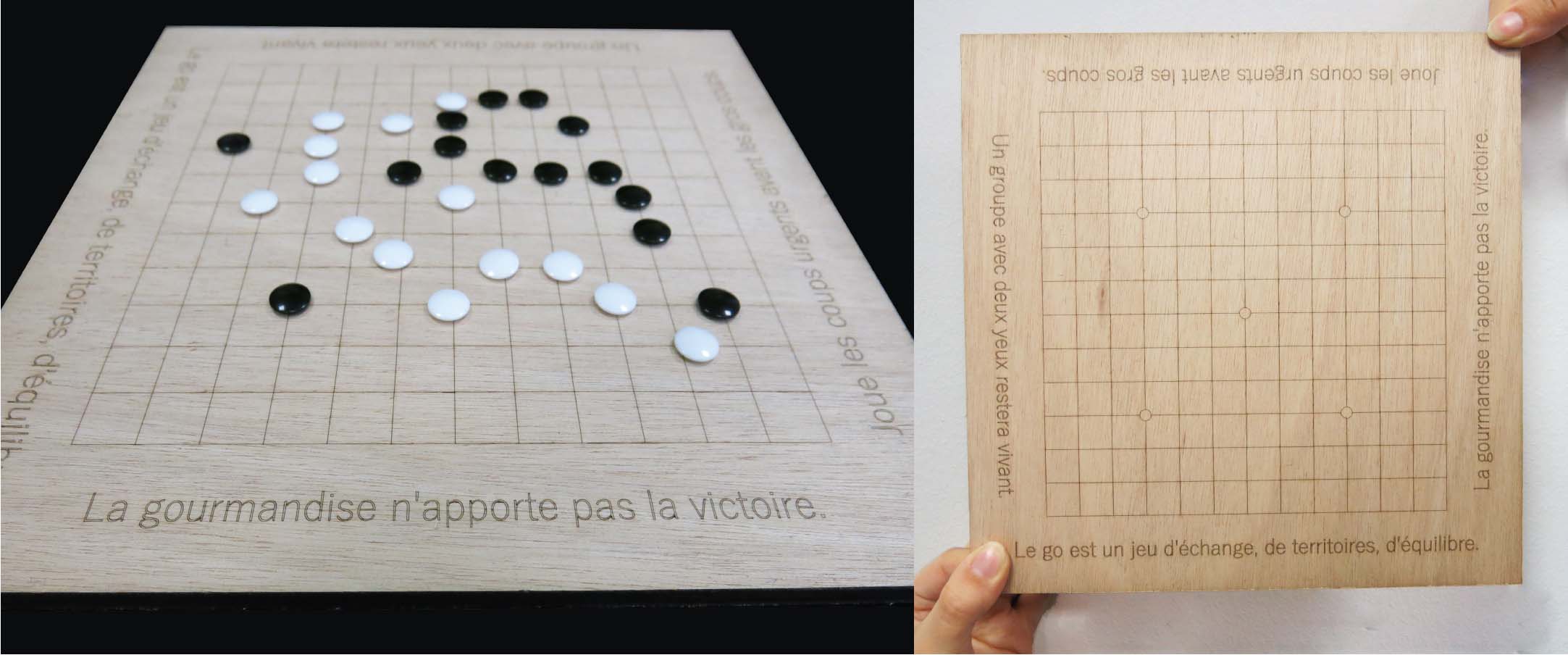

Hannah: I am just starting to learn how to play Go, taught by a friend, and we thought it would be great to have our own personalized board (it’s called a Goban). I find the rules of Go to be very poetic, so I wanted to have a board that has some of the rules engraved on it.

It says “Le go est un jeu d’échange, de territoires, d’équilibre” (“Go is a game of exchange, territories, balance.”), “Un groupe avec deux yeux restera vivant” (“A group with two eyes will stay alive”), “Joue les coups urgents avant les gros coups” (“Tackle what’s urgent before what’s impressive”) and “La gourmandise n’apporte pas la victoire” (“Gluttony doesn’t bring victory”).

Sculpteo: For how long have you been thinking of developing this project?

Hannah: Just a few weeks: a friend of mine friend taught me Go, we played a few games, and I started imagining making my board. I chose the board’s size: it has to be 19×19, 13×13 or 9×9 lines. I made a 13×13 lines one, which is an intermediate level of difficulty. We designed it together using SketchUp.

Sculpteo: What’s your favorite feature of Sculpteo’s laser cutting service?

Hannah: I like that at the last moment, when the file is uploaded, you can still choose which part of the design to cut and which part to engrave. And you can also erase some areas. I am a beginner with design software, and when I uploaded the file, I realized there were some lines there that I didn’t intend to be there. But removing them was quite simple! See here how to upload a file.

Sculpteo: What are the advantages for you of an online platform like ours?

Hannah: It is pretty amazing to realize a project that easily and that fast. One evening, I drew my design, I could upload it on the platform right away and know how much it would cost, make some updates… and a few days later I had the finished object.

Sculpteo: Have you thought of any hybrid projects, that mix laser cutting and 3D Printing?

Hannah: Yes, I’m thinking I might 3D print my Go stones. I’m still hesitating between laser cutting them and 3D printing them. I would love to have them in our acrylic material (I like the white and the black that are available), but then they would be flat: Go stones are usually curved at the edges, which makes them unstable – and that’s part of the beauty of the game.

So one solution would be to 3D print them in white and black polyamide.

For now, though I can use the stones from my other game.

Sculpteo: Any tips for our customers?

Hannah: Once I had designed my Goban with SketchUp, I wasn’t sure how to export it in the right format for laser cutting: I had used SketchUp for 3D design and 3D printing before, but never for 2D design and laser cutting. So I used our “Prepare your file for laser cutting using SketchUp” tutorial, which recommended to download the .SVG plugin “Flight of Ideas”.

So my tip is to turn to the Internet for tips!

When we launched our laser cutting offer, it came with plenty of resources to help people use it: from design tutorials to step by step explanations of how to upload your file and make sure you choose correctly what’s cut or engraved. I participated in the creation of these resources; it was nice to be one of their happy beneficiaries!

‘Sculpteo’s platform accepts a lot of file formats’

– Charles, API Project Manager

Sculpteo: In a few words, could you present your project?

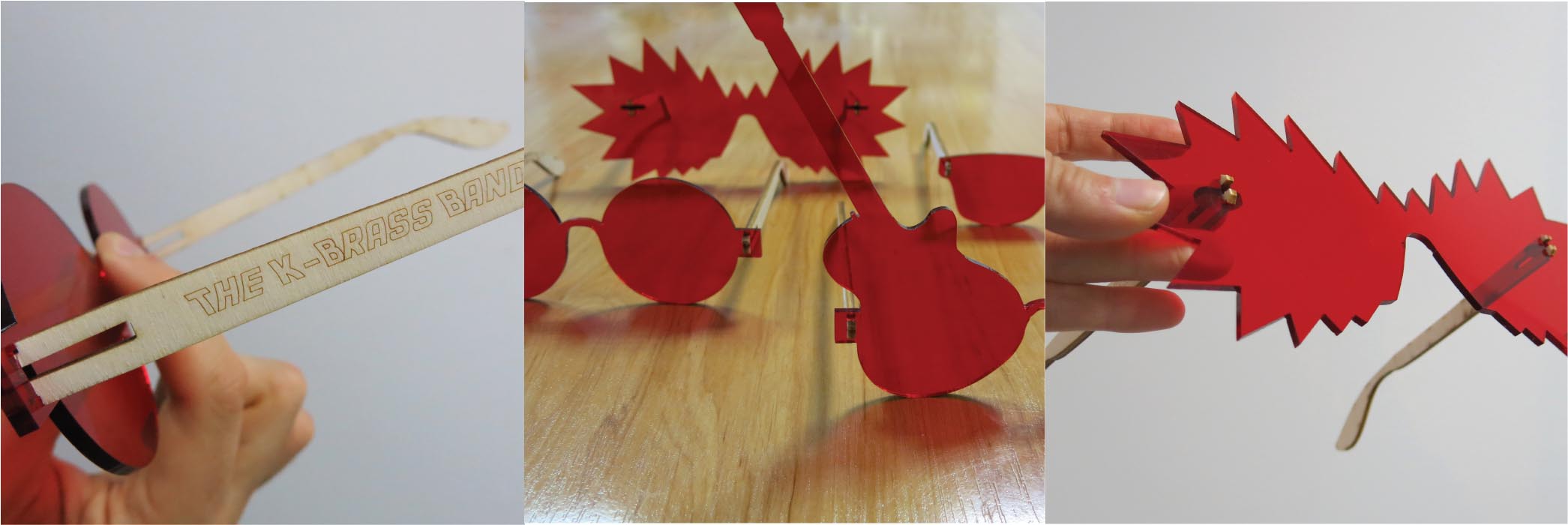

Charles: This project aims to make customizable glasses for my music band, The K-Brass Band (www.kbrassband.org), which is also an international solidarity project. We will travel around the World (South America, Asia) and play music with children. We wanted a funny distinctive sign. We had thought a lot about common outfits, or elements, for playing music together, in the streets or in pubs. We decided that everybody would have to wear a different red element.

Sculpteo: For how long have you been thinking of developing this project ?

Charles: Not very long! I didn’t know at all what original element I could wear in my band… But having one of our laser cut sample kits in my hands (order here!), I thought that making red glasses with our translucent red acrylic could be an awesome and original idea! It took me 5 minutes to find a 2D design on google, to make some modifications on Illustrator, and to order a first model on Sculpteo! For the branches of the glasses, I used MDF and engraving to write the name of my band.

Seeing that the result was of an incredibly good quality for a correct price, I thought that doing some other customized glasses for the rest of the band could very easy and quick!

Sculpteo: What’s your favorite feature of Sculpteo’s laser cutting service?

Charles: The display of the design allows you to be sure that it will be manufactured the way you want, at the good size, and the right operations (cutting, line engraving, surface engraving).

Sculpteo: How has the service helped you with your project?

Charles: The direct pricing tool allowed me to make several uploads and to compare my different designs, in term of price. Thanks to this tool, I was able to optimize very quickly the price of my glasses!

Sculpteo: What are the advantages for you of an online platform like ours?

Charles: I think Sculpteo’s platform is one of the best because it accepts a lot of file formats, and it is very tolerant with the quality of the design, where some other platforms are sometimes (not necessarily) more demanding.

Sculpteo: Have you thought of any hybrid projects, that mix laser cutting and 3D Printing?

Charles: Yes, I am working on a more difficult project, still for my music band. I would like my bass drum to illuminate each time I hit it. For this, I am going to build an electronic device, and a case for the device, which will be a mix of both technologies. I think I will use laser cutting for the front part of the case, with engraved graduations for potentiometers or switch buttons for example.

Sculpteo: Any tips for our customers?

Charles: Don’t hesitate to use vectorial design software, like Illustrator, even if you have never used them. They are very easy to take in hands, and it is easy to get some very good results after some practice!

Learn more on our laser cutting service here.

Read the other employees stories!

Laser Cutting Stories: what our team created #1

Laser Cutting Stories: what our team created #2

Did you like this article? Share it on Facebook, Twitter and LinkedIn!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook