2016: Year in Review at Sculpteo

Posted By Capucine Lonjon on Dec 21, 2016 | 0 comments

Almost the end of 2016! It has gone so fast for us! So many things we’re proud of. We’re presenting to you all what we achieved this year. Our last preparation of the year is for… CES 2017! Come and meet us, we’ll be very happy to share with you the upcoming projects!

You’ll find in this article

- our new laser cutting service

- our new materials: CLIP and solid black

- our new finishes: smoothing beautifier and paintings

- our new tools and production modes

- our new tips & contents

A new service: online laser cutting

In September, we launched a new laser cutting service. Combining all the online tools we had developed since 2009 for 3D printing, we enlarged our online service to digital manufacturing. Once again, we wanted to democratize the use of a technology, laser cutting. We created an intuitive interface specifically for laser cutting to allow you to download your design, repair your file, customize your options, and receive your part in a few clicks.

A few weeks after launching the service, we already had very good feedback from our customers.

Here’s the list of our materials:

You can order our acrylic in 17 different colors, in 5 different thicknesses.

You’ll find 2 different types of plywood, poplar and okoumé. Thanks to the wood texture, you can create unique objects and parts.

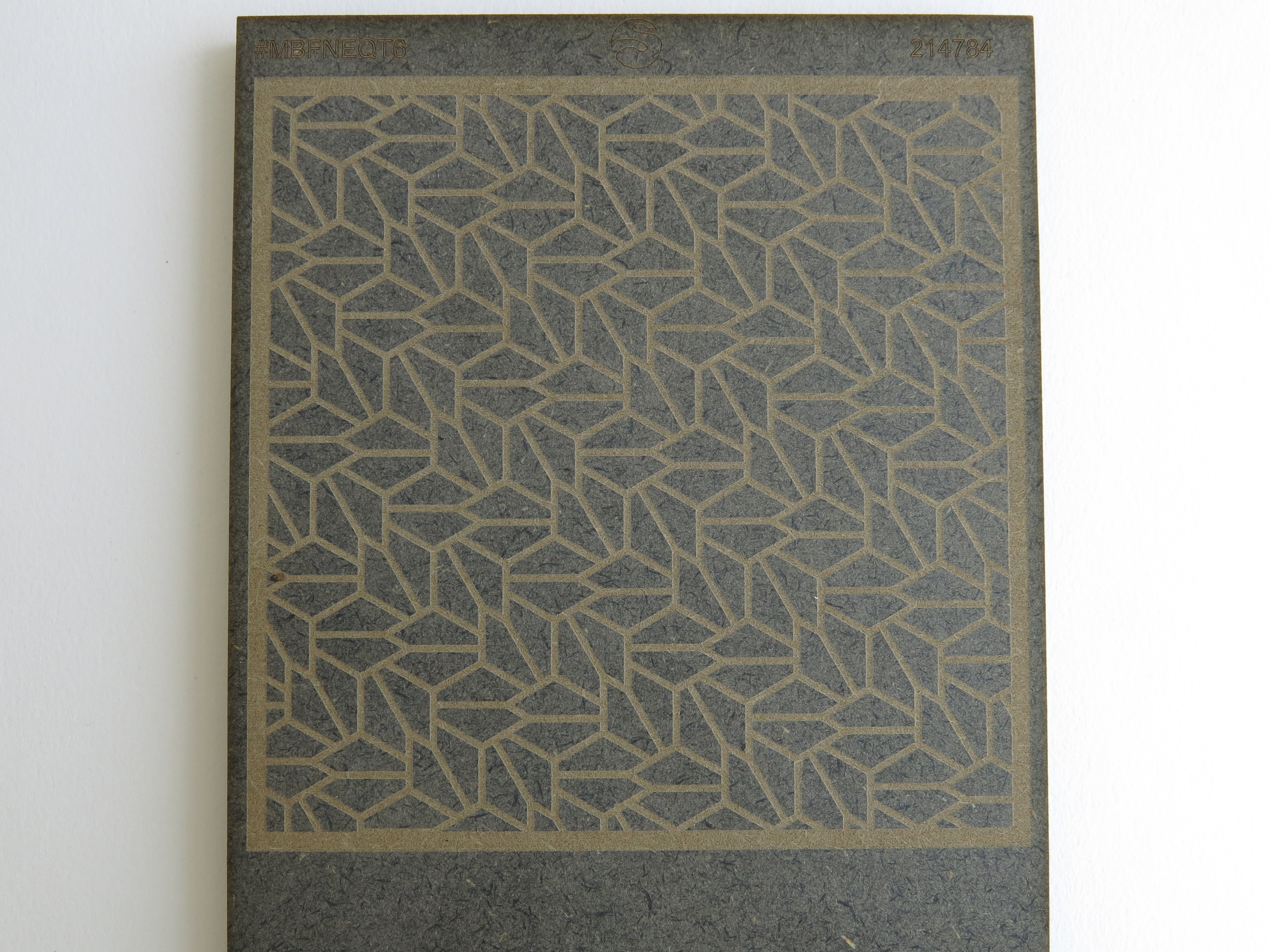

MDF (medium-density fiberboard) is very appropriate for engraving. You can choose among different colors: green, red, yellow, gray or black.

Three types of cardboard are available: corrugates, gray and cellulose, with 5 different thicknesses.

POM (polyoxymethylene) is a technical thermoplastic used for precision parts. You can choose between 2 thicknesses. It is an innovation after the launch. And we keep on enlarging our range of materials, according to your requests.

Go to our whole list of laser cutting materials.

See our laser cutting tutorials to help you design.

Get a sample kit!

We designed a functional and handy sample kit for you to test and have in hands our different materials.

Order our laser cutting sample kit now!

Ask for a specific need of material

On our online platform, we give you the possibility to request a particular material that isn’t in our laser cutting material list, thanks to our new tool “custom material”.

Laser Cutting Stories: What our Team Created

We designed a laser cut and 3D printing drone. The combination of both technologies is possible, today!

We are very happy to have a creative team. They show and explain to you their laser cutting projects. Discover more about Nespresso capsules holder, terrain pieces for tabletop RPG’s and a Chinese puzzle.

In the second story, discover a little birdhouse black-capped chickadees, an architectural model of the lands of the Palace of Versailles, and the mysterious Game.

And last, here’s the story of laser cut funny glasses and a Go board game.

Discover also models for original laser cutting business cards!

New materials

A family of new materials: Carbon CLIP Resins

We launched the new CLIP technology (Continuous Liquid Interface Production) in the beginning of 2016. We’re still the only online 3D printing service to provide CLIP 3D printing!

CLIP is a continuous 3D printing process, invented by Carbon 3D. CLIP resins parts have the particularity to look very similar to the injection molded models. What’s more, Carbon 3D is exploring these resins’ technical properties to have them used for real production or very realistic prototypes. The CLIP 3D Printing process is also incredibly fast compared to other 3D printing technologies.

Those four following resins went out of Beta this year:

RPU (Rigid Polyurethane): the very rigid black resin.

EPU (Elastomeric Polyurethane): our rubber-like material. EPU resin is rubbery, resistant, flexible and stretchable.

CE (Cyanate Ester): our beautiful translucent yellow material. Very well-known for its good resistance to high temperature!

Acrylate Prototyping: this Carbon resin is very solid and will give a very good aspect to your prototypes.

Solid Black Plastic!

Like our white plastic, solid back plastic is a fine black polyamide powder. It is produced thanks to the Selective Laser Sintering technology (SLS), based on a powder bed fusion process. Whereas white plastic is PA12, black plastic is PA 11.

The Invisible Material 🙂

Our engineers came up with a new amazing material that can revolutionize 3D printing: the invisible material. April 1st, 2016, is the only day when you can learn more about this ALS technology and Sculpteo’s invisible material.

New finishes: colors and smoothing

New colors for our white plastic!

We introduced new painting colors this year! The paintings are spread on your white plastic part using a spray gun, for a uniform application. This way, your part has a smooth surface and every detail of the printed object is maintained. The paint layer only adds 200 microns of thickness on average, and is more durable than our dyeing finish.

A Smoothed Surface for the White Plastic

We are very proud of this 2016 innovation. It comes as a result of experiments and research of our Research and Development department. Our new smoothing beautifier finish, created by Sculpteo, gives a smooth surface to your parts, making it look very similar to a plastic injection part.

New tools & production modes

Thickening

When designing for 3D printing, it is important to beware of the thickness of walls and edges. In fact, your 3D print has all the chances to be the best if the minimum thickness is respected. We conceived a thickening tool for our online platform that allows you to thicken your model directly on our platform. If your model is green, that means all is good! Orange and red colors will indicate if some zones need to be thickened.

Express Production Mode

We launched this year the possibility for you to receive your parts in 48h. Read our blog post about this innovation. You can select this mode when ordering your part on our platform.

Print It Anyway Option

We created the new status of expert user, as long as you made 5 or more successful orders with us. For all orders, before checkout, there is an automatic solidity check of your part on our platform, to make sure it’s not too fragile and it won’t break during 3D printing or shipping. Your part becomes green if all is right. Orange and red show you where the part needs to be made stronger. If we consider it not stronger, we might prevent you from ordering. Thanks to the print it anyway option, available if you are an expert user, you can choose to print your part, whatever our automatic tool tells you. You have the choice to print your part the way you like it.

Customized Part Orientation

SLS technology allows to reduce the visibility of the 3D printing layers. But because the powder is cooling down layer by layer, the whole part is not totally homogeneous. Depending on the orientation of your part in the 3D printing machine, your part will be fused differently and layers won’t appear the same. This is why, this year, we enabled you to choose your 3D printing orientation. This means choosing where and how the layers will be most visible, as well as the orientation of those layers. Learn more on this customized part orientation.

New tips & contents

New eBooks

Our study: The State of 3D Printing

We released the second edition of the State of 3D printing. In this year’s study, when we asked the respondents to declare the “purposes of their 3D prints”, 67% of the professionals answered Prototype, and 41% Proof of concept, confirming Takemori’s words. Learn much more info on the use of 3D printing, applications, ROI, consult tables and be aware of 3D printing sector!

Download the State of 3D Printing!

Top 21 Customer story collection: from 2014 to 2016

Drones, medical & research, robotics, the internet of things, mass customization, design, models for architecture and education and transportation: so many things we did with our clients and we are proud to show you!

Download our 21 customer stories eBook

The Ultimate Laser Cutting Guide

Discover the history of laser cutting, applications, design tips and laser cutting materials!

Download our Ultimate Laser Cutting Guide!

3D printing and Intellectual property

You’ll find in this eBook: a definition of each intellectual right according to European and American Law, the rights and obligations you can have if the object you want to print is protected, the people and companies who might engage their responsibility in case of infringement.

Download our eBook on Intellectual Property

The history of our technologies

From the 80s to today, discover what’s the history of 3D printing!

Learn everything about the history of the laser cutting technology. The different scientific steps to conceive lasers first than laser cutting. Enter an unfamiliar world!

Our Top 10 Articles

We interviewed XTreeE, a cutting-edge company that do 3D printing concrete to push the limits of construction. Learn more about the stakes of 3D printing in construction, XtreeE president’s advice for tech entrepreneurs.

Making wearables 3D printing clothes, Sculpteo, took up the challenge! Discover how fashion designers are using the technology (Iris Van Herpen, Karl Lagerfeld, Danit Peleg…) and the challenges the technology will have to take up (eco-friendly, user-friendly, affordability…).

To 3D print large items, it is more and more popular to use drones to scan the 3D model. Discover this example where they scanned a huge statue and tackled issues to turn the scan into a 3D model.

We interviewed Professor Daniel Kelly, who’s researching how to 3D print cartilage and bone. Discover the premise of this medical revolution!

Gears are very much used to create complex mechanical systems. Learn more on how to design gears for 3D printing!

What if a whole electronic good could be 3D printed in once? It is too early to see such a revolution, but 3D printing for electronics is already on its way and doing marvels.

3D printing spare parts can be seen as a manner to resolve the issue of the very controversial planned obsolescence. Learn more on planned obsolescence itself, its definition and companies that are already tackling this issue (MyMiniF actory, Boulanger, Audi…)

Medical equipment in accessible areas, fully customized medical tools, customized drugs, medical education and training, find the best way to treat cancer, skin and tissues, prostheses: 7 things that medical 3D printing already does.

Multi-material printing, molecules, conductive materials, bones, tissues, eco-friendly materials, carbon nanotubes, graphene, cemented carbide, concrete, pasta: top 10 future 3D printing materials (that exist in the present)

Discover how 3D printing transforms the automotive industry: concept cars, prototyping, 3D printed spare parts and 3D printed cars!

Top customer stories

We 3D printed an abbaye model! Learn more on the project, how came the idea of the mock-up and how we worked with the designer and the museum to conceive this model for blind people.

An interview of Nano-Racing: the accessible 3D printed drones.

We interview Robert Cheek from UVify, who talked to us about their 3D printed racing drones. Learn more on the project and on this very new eSport.

The Slovenian startup Noordung created an urban electric bikes, discover how they used our service to prototype and produce their bikes!

Discover this Top 10 3D printing projects you can try! Transmission models, hand prosthesis, robots, chess pieces models, design world clock, corset, camera lens, camera tripod, heddle looms and micro 105 FPV Quadcopter.

To go further, have a complete overview of our customer stories since 2014 with our very new eBook: the best 3D printing stories.

Tips to enhance your 3D Printing and Laser Cutting knowledge and know-how

Learn how to create a 3D model out of a picture!

This year, we decided to help you in accessing 3D scanners for your 3D models. We conceived a 3D scanners map that are near you & check the top 10 best 3D scanners for every budget.

Learn More on the Technologies

What metal technology for what application? Learn more about powder bed-based technologies, binder jetting and laser metal deposition technologies.

Do you know the difference between FDM, SLA and SLS? Learn more about each technology, their mechanical characteristics and what kind of plastic is used for each.

What is CLIP technology vs SLS? We give you selection criteria to as close as possible to your projects needs.

And what about SLS vs Polyjet? Be unbeatable on 3D printing technologies!

Prepare your 3D prints better than ever

Here are some tips to help you understand your 3D printing dimensions: how to choose the unit measure of your CAD file, keep in mind dimensions and weight constraints of your 3D printing machines and modify the size of your design once it is uploaded on our platform.

We give you our best tips about wall thickness for 3D printing: thickness of the walls depends on the size of your model, the material you use, the shape of your model. Learn more about our thickening tool that can have you avoid redesign your model if necessary.

Here a 5 tips to reduce your 3D printing costs. Have a look before starting your project!

How to implement 3D printing in your office department? We give you tips to launch a business or activity in 3D printing.

What software should you use

Here’s an overview of the top 8 software for laser cutting: Illustrator, Inkscape, SketchUp & more.

We did a compilation of the top 7 3D modeling software with Linux: Blender, FreeCAD, HeeksCAD & more.

Design with your kids! Here’s a top 8 cad software for kids: Solidworks App for Kids, Tinker CAD, Leo CAD & more!

What events did we go to?

This year, we were present at many events! CES was the very first event of 2016! We presented a 3D printed fashion collection. From the April 4th to 8th, we were to the Industrie tradeshow in Paris, then in May, in went to the Rapid Fashion Show to present our Virus Collection. We were also at the Additive Manufacturing Europe by the end of June, where we presented results from our second edition of the State of 3D Printing. We went to 3D Print Lyon, in the beginning of October, where Marine Core-Baillais, our CMO, had a talk about 3D printing and personalization. And last but not least, we were at Midest, a global show for all industrial subcontracting know-how; our account manager Nicolas Mathian took part of a talk about 3D printing in the aeronautic industry.

Our next tradeshow is at CES 2017! Meet us there, we’ll be pleased to meet you and discuss new resolutions for 2017.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook