Customer 3D Printing Stories: UVify Racing Drones

Posted By Hannah Bensoussan on Dec 21, 2016 | 0 comments

A few weeks ago, we published the story of Nanoracing, one of our customers, who builds small-size racing drones. Today, we present to you another of our customers who specializes in racing drones: UVify. Their Head of Business Development, Robert Cheek, talked to us about their shift from autonomous technologies for vehicles to First Person View drone racing, their prototyping experience with our online 3D printing service, and gives us entrepreneurship tips.

A particularly interesting interview if you’re curious about the odd and fast-growing eSport phenomenon that is Drone racing!

We’ll be at the Drone Rodeo with UVify, the premier pre-CES Drone Event. Meet us on January 4th 2017 at our booth! UVify will have some drones on the race: come and support them!

Part 1: About UVify and the Drone Racing Phenomenon

Sculpteo: What is UVify?

Robert Cheek: UVify is an American tech company (our HQs are in San Jose, CA) with Korean roots. We first got funding from robotics: we were building AI, robotics and autonomous systems – self-driving cars, for instance. Eight months ago, we made a shift, to focus on racing drones. We saw it as an exciting opportunity and thought high-speed drones would be a perfect way to show our technology and expertise. Today, we develop and build racing drones as well as robotics technologies, sensors, and artificial intelligence systems.

Our one-line pitch: “Drones, AI, robotics, and next-generation eSports in a fast-climbing company”

S: Who’s the UVify team? What’s your background?

RC: Unlike some other drone companies, our team is composed of some very experienced hard-science experts. Our three founders are Hyon Lim, Chulwoo Park and Kyunghyun Lee:

Our CEO, Hyon Lim, whose nickname is “Rocket scientist”, has a PhD in mechanical and aerospace engineering. He was the first person to write drone research papers while at Microsoft Research, and is one of the leading experts in machine vision, a field of AI.

Our CTO Chulwoo Park, holds a PhD in Mechanical engineering and has conducted serious research about control algorithm.

And our CPO, Kyunghyun Lee, holds a Masters in Mechanical and Aerospace Engineering.

The very scientific background of our three founders is one of our key advantages!

As for myself, I am the Head of Business Development, and based in San Francisco, but I go back and forth between SF and Seoul (South Korea) (there are 7 people in the Seoul office).

We also have 2 pro pilots in Canada: Paul Baur (pilot name SkinLab FPV) and Andrew Meyer (pilot name MayDay90) who fly both for Team Canada and Team UVify.

S: Can you tell me about your product a bit more concretely? What’s special about the racing drone you’re creating?

RC: Our drone is called Draco, and goes along with replacement and upgrade components. It will be sold as a standalone unit with nylon or carbon fiber arms, in a variety of bundled configurations with radio transmitters, goggles, radio controls, and/or carrying packs.

Our core technology is called SLAM. It’s a machine vision technology that we develop in-house, and will unveil in another drone.

As drone racing is a very recent phenomenon, pilots often create their drone themselves, using a selection of frames and components from various manufacturers. What we’ll offer is an out-of-the-box solution that is competitive in terms of performance, race consistency, customer experience, product, design, and technology.

We hope to have Draco flown by the world’s best Fitst Person Vision pilots, who we’ll sign to our team!

S: Who are your clients?

RC: Our target market is both made of the pro racing drone market and the emerging consumer racing drone market.

S: Which stage of your development have you reached?

RC: We haven’t gone into mass production yet: we will enter this phase at the beginning of January, and announce commercial sales at CES 2017. We’ve been iterating and creating prototypes, some of which are being raced by professional drone racers, at various competitions.

At the moment, we’re very present at drone events: for example, we were the sponsor of the Korean national team at Drone Worlds in Hawaii last October, which took 2nd place, beaten only by the US team, out of more than 40 national teams!

S: Why do you think drone racing is a growing opportunity?

RC: Drone or First-person View (FPV) racing is the fastest-growing sport in history. According to estimates from research firm Markets and Markets, the global drone market will grow annually by 32% between 2015 and 2020 into a $5.6 billion industry. Drone racing is going to be a very interesting cultural phenomenon to watch: it’s just at its beginning stage. Technology is evolving very quickly and people are along with it: we’re probably going to see things that we didn’t expect, from a new generation of players and competitors. Expect the unexpected from it. It’s bringing video games into real life, and I believe it will become, in a way, the F1 of the 21st century, a symbol of the current generational cultural shift.

S: Do you think we should expect to see drones flying in the streets any time soon?

RC: Yes! It’s already happening! In Korea, you can see free fly areas. What is lacking still is specific legislation. But it is developing, and I believe it will keep developing.

Part 2: Your experience with 3D Printing and Sculpteo

S: What role does 3D Printing have for UVify?

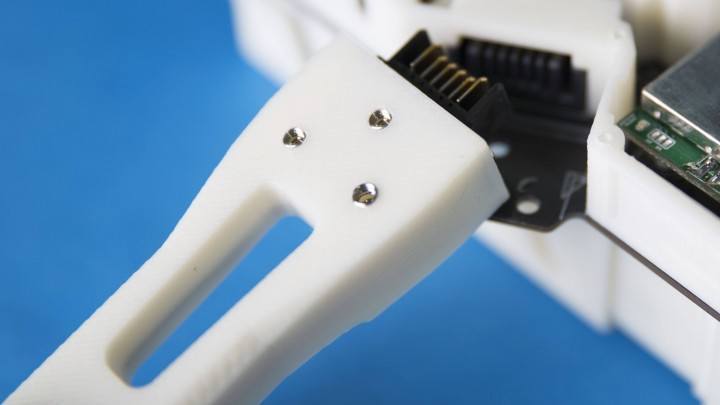

RC: We used and are still using 3D Printing in our activity: we’re creating at least a new iteration every week thanks to 3D printing prototypes. We’ve made more than 80 iterations already, and are constantly improving our models! Our process is more than rapid prototyping: it’s uber rapid prototyping! And Sculpteo’s 3D printing service has been key to this process: this pace can’t be achieved with traditional manufacturing methods.

S: Do you only create prototypes with 3D printing, or also finished products?

RC: We intend to do both prototypes and finished products with 3D printing: the drones that are being flown at the moment were built with Sculpteo technology. For now, we are still in our prototyping stage. When we go into our production phase, we’ll also keep using Sculpteo’s 3D printing service, as our work is in some way experimental: we’ll create small production runs to test the viabilities of different options.

S: What was your prior experience with 3D printing before you used our online 3D printing service?

RC: We used many different 3D printing services and models. Because we needed to abide by the best possible quality standards, we decided to go with Sculpteo.

S: What did you test during the prototyping phase?

RC: We tested the viability of our designs: mainly aerodynamics, performance, design. Drone racing is a spectator sport, which will be practiced and watched: that’s why our drones have to be fast and need to look good.

S: What did it bring to the table to use a 3D printing service? Any Sculpteo tool in particular that you appreciated?

RC: We’ve been very happy with working with Sculpteo. What we like in particular is the fast lead time and reliable quality. What’s great is that we don’t have to think about how the object is made, we can simply trust your 3D printing service to do the job. It truly helps us in rapid prototyping.

PART 3: Tips for startups taking their first steps in 3D printing and digital manufacturing

S: Can you share some insights from your entrepreneurship experience?

RC: Hire people who are passionate above all else. The team has to have a clear vision that they share and the wherewithal to do what it takes to get it done. Work hard and be nice.

S: For you, what does it mean, today, to master 3D printing?

RC: To realize what we’ve seen with our mind’s eye into the real world.

S: Which tips would you give to someone who’s getting into 3D printing for their business?

RC: Use Sculpteo! As I said already, our experience with our online 3D printing service was very satisfying. Using such a service means iterating problem-free. We don’t need to worry about the machines, and we can focus on product development and business development.

That’s my tip: it’s important to have a partner you can trust, so you can keep stress to a minimum, and focus on what you know and do, on the core of your activity. Know who you can work with, and keep those valuable partners close.

We were very happy to share this customer story with you. Visit UVify’s website! To read about our other clients testimonies, read our Customer Stories Ebooks.

You can also read our Application pages to get inspired by the many 3D printing applications, and launch your 3D printing project. Upload your design here!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook