3D printing and solar energy in Tanzania: Simusolar

Posted By Amandine Richardot on Jul 26, 2017 | 0 comments

In Tanzania, more than 1 million small businesses and 30 million people lack productive equipment and energy for it, which represents 75% of the population. Simusolar is a company created in 2014 which develops and implements small-scale sustainable solutions to bring solar energy to the rural population of Tanzania. For instance, they developed solar-charged LED lights for fishermen from the Lake Victoria, to replace their petrol lights when they fish at night. This company with a great social impact chose Sculpteo as one of their partners to 3D print parts for them. Today, we make you discover how 3D printing can truly change things when it comes to solar energy.

Part 1: Discovering Simusolar

Sculpteo: Can you present Simusolar?

Simusolar serves rural Tanzanians with productive tools and equipment financing payable in installments via mobile money. Equipment includes both power generation (solar) and its applications: water pumps, small business equipment, home lighting, and more. We integrate our custom circuit board into the equipment so that, using GSM technology, we are able to remotely control and monitor the equipment.

Who’s on your team?

Co-Founder and CEO Marianne Walpert has over 10 years experience serving off-grid Tanzanians and the team has over 70 years combined experience in solar. David Katz, CTO, pioneered off-grid solar distribution in the late 1970s and built up one of the largest distributors in the US. CFO Michael Kuntz, CFA, has been working in financial services and microfinance for over 15 years and has led organizations in Nigeria and Peru.

Who are your clients?

Our clients are smallholder farmers, fishers and rural residents looking to improve their incomes through productive equipment powered by solar electricity. Many of them have several sources of income because no single one can be scaled without capital. The lack of financial services and accessible energy are obstacles.

Which projects are you currently working on?

We have been selling fishing lights to support the night fishing community on Lake Victoria in Tanzania, responsible for the largest protein source in the Lake Zone. In parallel, we are piloting our water pumping systems with several communities while introducing equipment for the poultry sector.

Part 2: How Simusolar uses our 3D printing service

How do you use 3D printing? Which advantages does it bring to you?

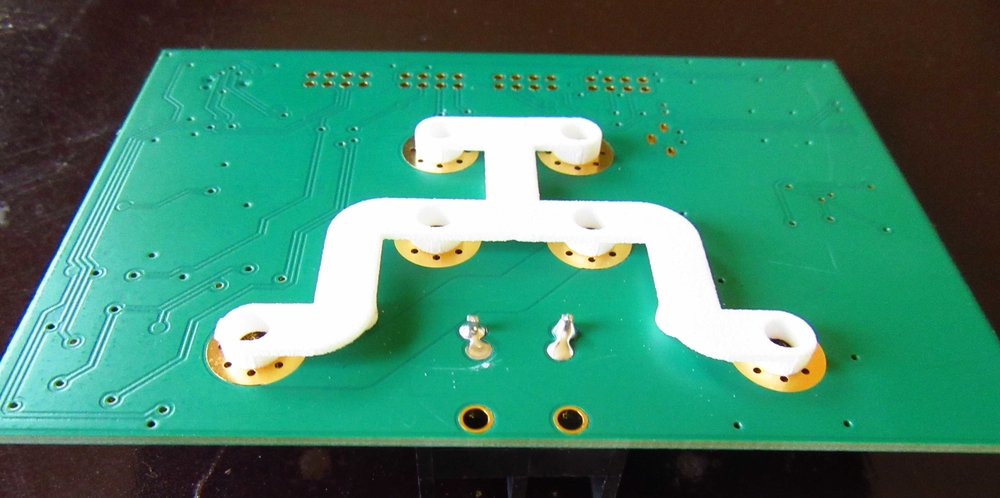

We needed a custom-made small, complicated part made of an electrically insulating material to add to our circuit board installation. We considered injection molding, but the tooling cost was too high. Since we only needed 100 parts for an alpha run, why not 3D print them?

We used the services of Cameron and Chris at Tacklind Design, a subcontractor to Simusolar. They have experience with all types of 3D printing.

How does Tackling Design get your 3D files?

Tacklind Design uses SolidWorks for 3D modeling.

Which 3D printing technologies do they use?

They use a variety of 3D printing technologies including FDM, SLS, and SLA.

Do they use other digital manufacturing techniques?

They also use laser cutting and CNC milling as the project requires.

Part 3: Insights on Simusolar’s field

Which opportunities does 3D printing bring to your field?

Thanks to 3D printing, we are able to rapidly innovate components for our products thanks to the speed of manufacture and the reasonable cost of small batch production.

Which advice would you give to someone starting in 3D printing?

Most vendors charge a base fee plus to start a 3D print then add one for material and machine time. Sculpteo broke this model. This means they can provide small complex parts for as little as $7 each.

Which unpredicted challenges did you encounter, and what did you learn from them?

Tacklind Design has semi-pro FDM printer in house. They tried 3D printing the first sample. They had to “dumb down” the details to make it work. In the end, it was a waste of time which equates to more expensive 3D prints. The Sculpteo SLS process has much higher 3D printing resolution and makes more robust parts at a reasonable price. It is our go-to 3D method of choice for most projects.

Did you enjoy this customer story? Discover some other great projects from our customers in our previous blog posts: 3D printing and breast reconstruction, 3D printing drones, 3D printing prosthesis!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook