3D printing and laser cutting: Which manufacturing technique should you choose for your project?

Posted By Lucie Gaget on May 2, 2018 | 0 comments

At Sculpteo, we are offering two different services: a 3D printing service and a laser cutting service. Both of these two manufacturing techniques are offering the possibility to use different materials,. We are going to see in this blogpost what the specificities of each of these manufacturing techniques and what their benefits are. Which one would be more appropriate for your project? And why? Follow the guide, and choose between 3D printing and laser cutting!

Rethinking your manufacturing process

Choosing the right manufacturing technique

When starting your business or rethinking your manufacturing process, it can be really hard to find the best manufacturing technique for your company. You might be looking for a manufacturer for your business, both for production or prototyping, and you obviously want to find a reliable partner offering the best quality for a lower price. In this case, digital manufacturing might be the solution.

A lot of industries are making the most of digital manufacturing. These manufacturing techniques could perfectly fit your company and help you to reach all of your professional goals. But how do they work?

The benefits of digital manufacturing

In order to use digital manufacturing, you have to create your 3D or 2D projects on your computer. You can create any design such as mechanical designs, architectural design, artistic designs, even the most complicated ones!

Sculpteo’s services are helping companies to develop their products everyday, using 3D printing or laser cutting. These manufacturing techniques have their own advantages, their differences but also their similarities. Indeed, both of these techniques will speed up your manufacturing process and will help you to create accurate 3D objects. They are also great tools for mass customization, it becomes really easy to get custom-made items at a lower price thanks to digital manufacturing, as only the 3D or 2D model needs to be modified to make a new object.

You want to make the most of digital manufacturing but you don’t know which of these manufacturing methods will be the most adapted to your project? Don’t worry, we are going to help you choose between additive manufacturing and laser cutting.

What is 3D printing?

How does it work?

3D printing is a manufacturing process in which a part is built by adding material layer by layer, by opposition to subtractive methods where material is being removed to create an object. First, you need to create a 3D file using a 3D modeling software and choose the material that you want There are actually different manufacturing methods, it depends on the materials and techniques that you choose and need for your project.

There are powder-based methods, creating parts additively by sintering fine polymer powder particles, to fuse them together locally with a laser. You can get 3D printed plastic parts using this method. There are also processes to create 3D printed resin parts, using a liquid that is solidified by UV light layer by layer to create rigid and highly detailed parts.

Learn more about 3D printing technologies right here.

You can 3D print:

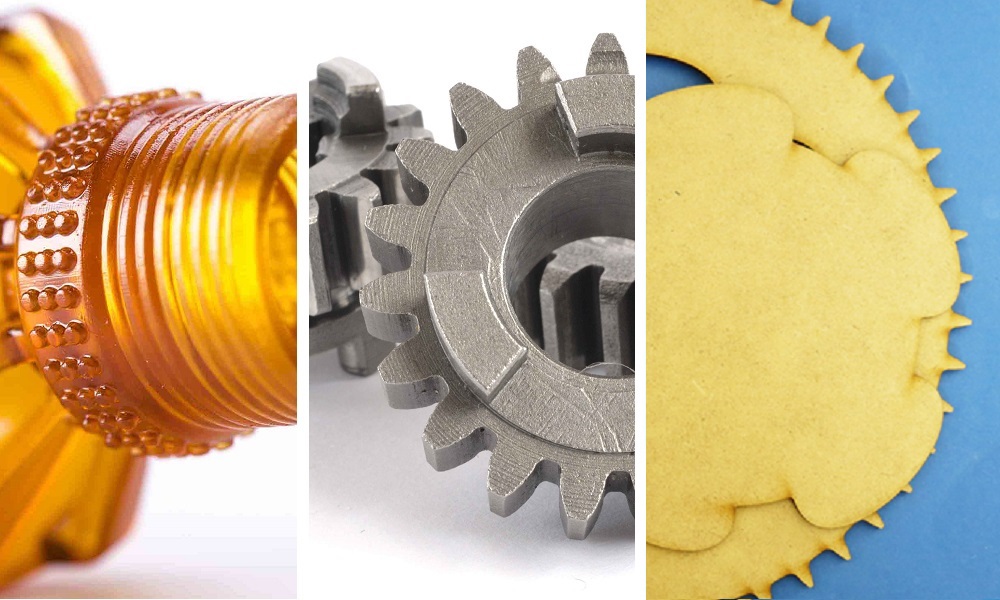

- Plastics with technologies such as Selective Laser Sintering or Multi Jet Fusion.

- Resins with technologies such as the CLIP technology or Polyjet

- Metals with technologies such as Selective Laser Melting, Direct Metal Laser Sintering, or Binder Jetting.

All these technologies also offer the possibility to print with different 3D printing materials. The opportunities are really numerous, that is why 3D printing can be a really convenient manufacturing technique for diverse projects. If you want to use 3D printing you will also have to choose the 3D printing materials really adapted to the parts that you want to create.

What kind of projects is it possible to create with 3D printing?

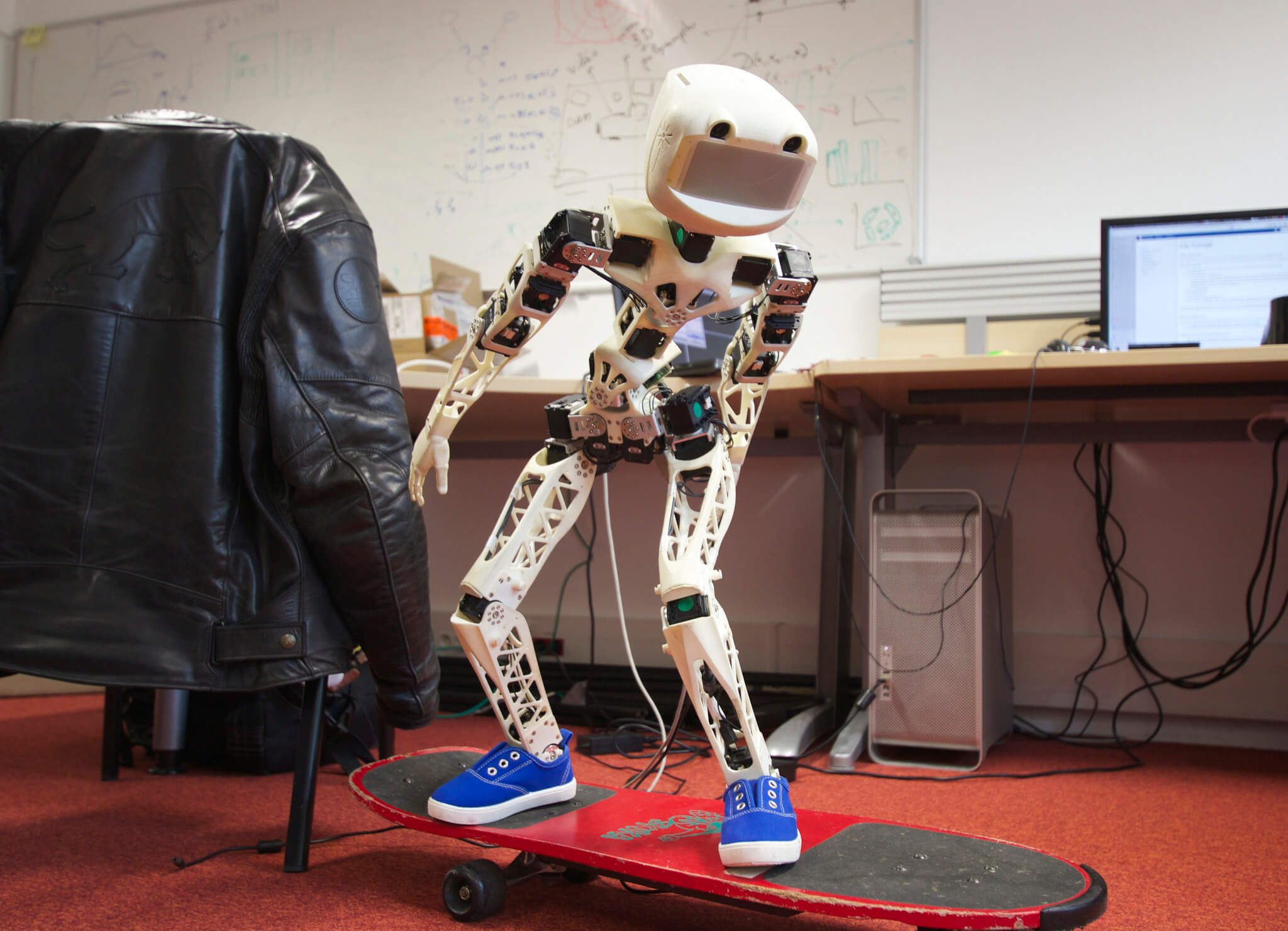

3D printing actually allows to use a wide range of different 3D printing materials and techniques, leading to really impressive projects: 3D printed homes, 3D printed jaws, 3D printed prostheses or 3D printed fashion accessories.

This technology is now useful and essential for diverse industries, from healthcare to fashion and architecture! It is even possible to create electronics projects, such as 3D printed robots.

https://www.poppy-project.org/fr/robots/poppy-humanoid

What is laser cutting?

How does it work?

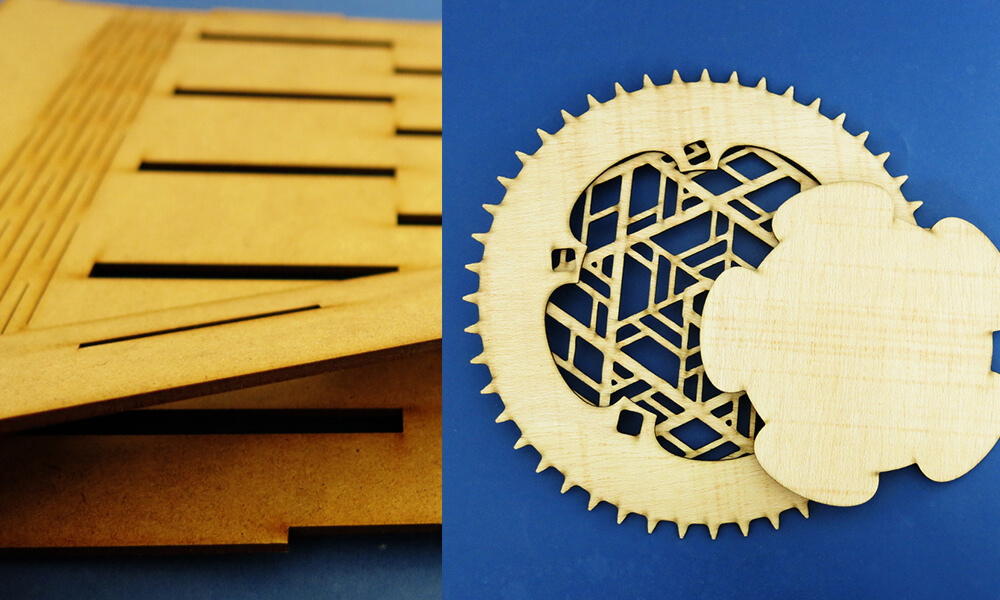

You actually have the choice between two different techniques: laser cutting or laser engraving. Laser cutting is a technology using a high-powered laser beam to actually cut the material, while laser engraving will simply engrave your part. This manufacturing technique will turn your 2D design into a real object.

What kind of projects is it possible to create with laser cutting?

If you choose to use this manufacturing method for your project, you will access a wide range of materials, from acrylic to wood. What is it possible to laser cut or engrave?

Thanks to our laser cutting service, you can laser cut or engrave acrylic, plywood, MDF, cardboard, POM. This will offer a lot of possibilities to create your projects, especially to create large parts at a lower cost, but still with interesting details. Laser cutting will be the perfect solution to make original custom items, such as custom visit cards or decorations.

3D printing or laser cutting: What is the best for you?

Both of these manufacturing techniques are efficient and quick to make good prototypes or even great end-use products. Some of your products might be doable with both! But one of these techniques is always more adapted than the other, it always depends on the nature of the project, the material, the size and the final use of your parts.

You will have to ask yourself several questions. Is your project doable by assembly of different laser cutting parts? Will your part be adapted to the 3D printing process or will they take too much space in the build chamber?

The benefits of 3D printing

Prototyping and production: Everything is possible with additive manufacturing

Additive manufacturing will really allow you to produce high quality prototypes. Using a 3D modeling software, you will be able to create simple or complex designs, and make as many iterations as you need at a lower price.

Additive manufacturing will really help you to create high quality prototypes but also finished products, at a lower cost than with techniques such as injection molding. By using 3D printing, you will definitely save time, money and improve your product development process.

Create complex designs

3D printing could really be a great asset for your company. Indeed, everything is now 3D printable from fashion accessories to mechanical devices. Professional 3D printers are now able to create any items, even with complex design, impossible to make in just one part with any other manufacturing technique.

Make the most of the various 3D printing materials

It is an interesting methods if you need to manufacture complex and resistant objects made in one part. Among the variety of materials available, you will certainly find one with properties meeting your expectations. Does your part need to be heat resistant? Flexible? Do you need special finishings? Find the perfect materials and all the options available for your project on our material pages!

If you are working in the medical field and need a biocompatible material, 3D printing is certainly the best choice. For instance, you can use our biocompatible resins to create prosthesis or other kinds of medical devices. That wouldn’t be possible with laser cutting, that is why, for these kind of project, additive manufacturing will be the perfect solution!

If you need to create a metal 3D object, 3D printing is the perfect method for you. For instance, you can 3D print stainless steel, or aluminium.

The benefits of laser cutting

Work on bigger parts and flat surfaces

The main difference between laser cutting and 3D printing is that laser cutting only allows to work on flat surfaces. If you need a 3D objects, you will have to assembly laser cut parts. It can still be a solution to give life to your projects, it will be cheaper, especially if your are planning to make big sized project. Indeed, laser cutting is great to work on bigger surface than additive manufacturing.

As this manufacturing technique is convenient to create large parts, at Sculpteo we used it to create tables for an exhibition.

You can choose your dimensions, and it will create your object with a really high precision. Keep in mind that some projects will be cheaper to produce using laser cutting, as they might be a little bit too big to be 3D printed and thus, they would be quite expensive. The price is really one of the biggest advantages of laser cutting. It is really becoming a convenient and efficient manufacturing techniques if you need to create products such as furnitures.

Many materials available for your laser cutting projects

Thanks to the various materials offered by this manufacturing technique, laser cutting will be perfect to create diverse custom items, such as custom visit cards, boxes, decorations, furnitures. For instance, to created our tables, we used MDF material (Medium-Density Fibreboard). You could even make circuit boards. Watch this video to see how it is possible to make laser cut circuit boards:

Like 3D printing, it can be great to produce amazing jewelry, but it will allow you to use different materials like wood. Check out our last blog post about the most impressive projects made using laser cut wood, it could be a great inspiration for you!

If you need to work on wooden parts, you will have to choose laser cutting instead of additive manufacturing. Indeed, it is not possible to work on wooden projects with professional 3D printers yet, laser cutting is way more adapted. You will get laser cut objects with a high quality.

But wood is not the only material that you can laser cut. Acrylic is also a great material, offering a lot of possibilities in terms of transparency and colors.

Make the most of the design possibilities

You can laser cut a lot of different designs, it is possible to make complex creation with this technique, that is why it is particularly useful if you need to create custom-made parts. You can also combine it with the use of laser engraving to add even more details and personalization on your products! You will see, laser cutting will be the perfect solution to make really accurate parts.

If you are planning to create your projects with laser cutting, be sure to choose the best software to create your 2D design. And if you need a little help, we have laser cutting tutorials available on our site. It will allow you to get designs prepared for laser cutting.

Can’t make a decision? Use both!

You definitely can’t choose because you find that these two manufacturing techniques are both amazing? Don’t choose and use both. You can totally build an entire project using these two techniques. That is actually what two of our designers did here at Sculpteo: they created a bike with 70% of parts made using additive manufacturing and laser cutting. Check out how our designers created this project.

You can see that both 3D printing and laser cutting have big advantages and could improve your manufacturing process. If you still have questions about these two manufacturing techniques, don’t hesitate to contact our sales team. They will help you to make the best choice to manufacture your parts! Once that you have your 2D and 3D designs ready, you can upload them on our 3D printing service or our laser cutting service, we will send you your parts in a few days!

If you are interested in 3D printing and laser cutting, subscribe to our weekly newsletter to get all the latest news about digital manufacturing.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook