Faster 3D printer and antibacterial 3D printed cellulose: MIT is going further!

Posted By Lucie Gaget on Dec 12, 2018 | 0 comments

MIT is always at the forefront of innovation when it comes to additive manufacturing and we see that once again, they found new 3D printing advantages. We can now be sure that everything is 3D printable: Researchers from MIT developed an amazing antibacterial 3D printed cellulose. They also unveiled a new 3D printing technology, which might be 10 times faster than other traditional 3D printers.

Let’s discover in this blog post how these two innovations will be useful for the evolution of additive manufacturing!

3D printing faster: A new experiment!

You may know it now, but additive manufacturing allows for cost and time savings. But this manufacturing process could become even more efficient and faster in the following years. Indeed, we saw it at Formnext, with the new 3D printer announced by EOS: printing speed is at the center of all attention.

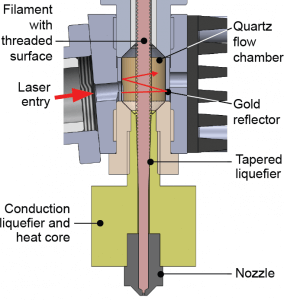

MIT researchers developed a faster 3D printer by matching threads on the filament and nut to ensure maximum contact between them. This way, the system can transfer a high force to the filament without losing grip. With standard 3D printers using the deposition technology, the filament is pushed by two small, rotating wheels and it can go too fast, otherwise, the wheels lose traction.

Here is the system developed by MIT researchers:

MIT

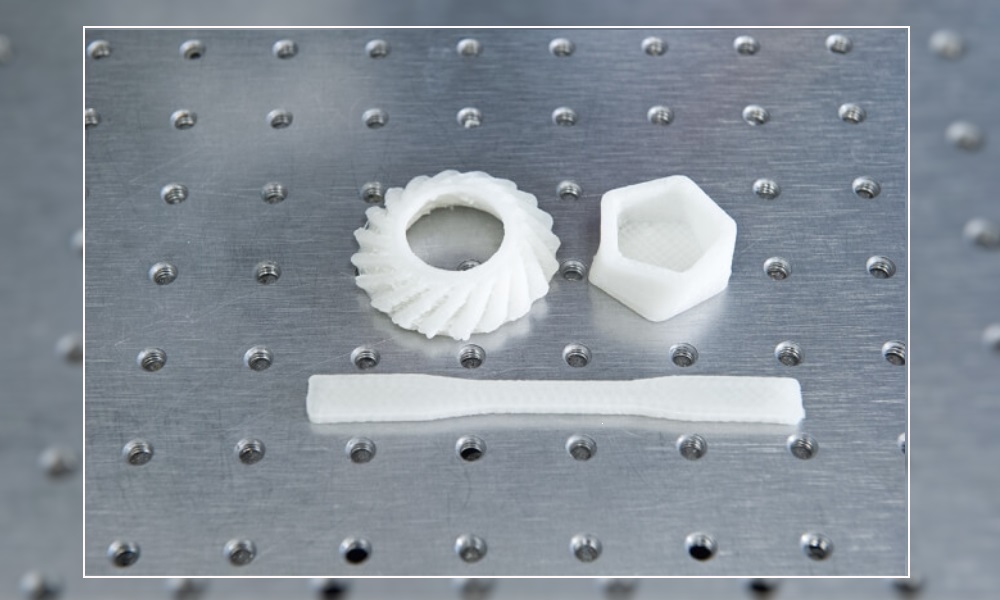

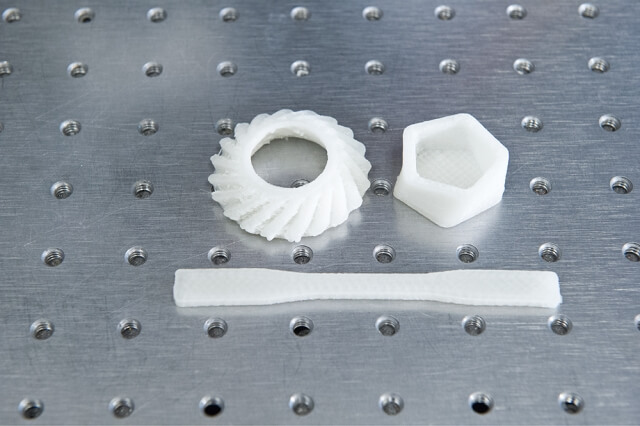

This new technology has been tested in order to print a few objects, a pair of eyeglass frames have been 3D printed in less than 4 minutes

This new technology is amazing but it is not the only novelty unveiled by these researchers regarding 3D printing! Indeed, they are also looking for the development of new materials and especially eco-friendly materials!

MIT

3D printed cellulose

Advantages of this new 3D printing material

Their will to develop eco-friendly materials led to the creation of 3D printed cellulose. But why cellulose? This material really offers great advantages as it is biodegradable, quite resistant, and inexpensive. One of the main advantages of this material is its chemical versatility.

Hart, of the researchers of the team, affirms “You can modify cellulose in different ways, for example, to increase its mechanical properties or to add color”. 3D printed cellulose could totally offer new opportunities in the 3D printing world.

Difficulties during the 3D printing process!

Cellulose only has one disadvantage making it difficult to use for 3D printing, it can decompose when heated, which doesn’t make it really convenient for an additive manufacturing process. Researchers have to admit that past efforts regarding 3D printed cellulose were unsuccessful! Heated up, the cellulose decomposes before it becomes sufficiently flowable to extrude from the nozzle of a printhead.

To avoid this problem researchers started to work with chemically treated cellulose, with fewer hydrogen bonds: cellulose acetate. The mixture spreads across the print bed and the acetone quickly evaporates. Once the finished object is ready, immersing it in sodium will remove the acetate and restore the cellulose with its full network of hydrogen bonds.

Using this technique allowed MIT researchers to manufacture complex 3D printed objects using cellulose material. The mechanical properties of these printed objects are actually really good. Indeed, after the sodium hydroxide treatment, the strength and stiffness of the 3D printed parts were superior to those of parts made out of commonly used 3D printing materials.

As this material is quite cheap and eco-friendly, 3D printed cellulose appears to be quite promising.

MIT

Antibacterial cellulose

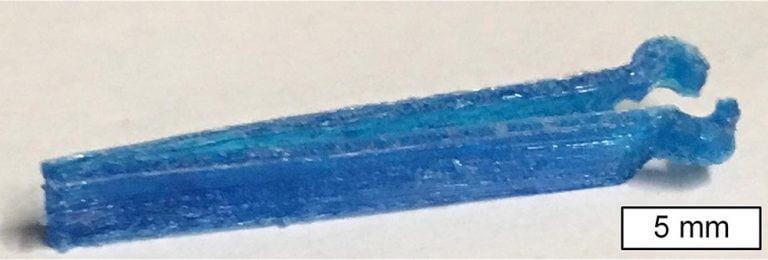

MIT researchers even went further with this 3D printed cellulose experiment. A researcher tried to add antimicrobial properties to a 3D printed cellulose part. Here is the experiment: They started to print a series of disks, some from plain cellulose acetate and some with an antimicrobial dye added. Then, they deposited a solution with E. coli bacteria on each one.

Analysis of the bacteria surviving after 20 hours showed that the disks made with dye and exposed to the light had 95% fewer bacteria than the other ones. The result is actually really impressive and could be interesting for medical 3D printing and surgical devices!

What do you think of these 3D printing innovations? Share your views with us in the comments! Do you have a 3D printing project? Let’s talk about it! If you already have your 3D file you can upload it on our online 3D printing service and you will get your 3D parts in a few days.

You can also subscribe to our weekly newsletter to get all the latest news about 3D printing innovations!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook