Introducing new engineering-grade metal filament Ultrafuse 316L: now available from Sculpteo

Posted By Kat Plewa on Nov 5, 2019 | 0 comments

Did you know it is possible to 3D print great mechanical parts with metal filament? Discover the benefits of high-performance metal 3D printing with our new material: Ultrafuse 316L. It has some outstanding properties at a great price! What makes Ultrafuse 316L so special? Let’s find out!

Q: What is the Ultrafuse 316L material?

A: Ultrafuse 316L is a metal 3D printing filament for FDM/ FFF technology. It is an industrial-grade material aimed for professional uses. It has some outstanding properties, especially for mechanical and engineering parts, and can be used at different stages of the design process, from prototyping to end-use parts.

Ultrafuse 316L is composed of stainless steel 316L powder and a polymer binder. The ratio is an impressive 90% metal to 10% binder. Thanks to the binder, the filament softens in the nozzle and allows for a smooth flow of the material. The binder is later removed leaving a pure metal part.

Q: How does the process work?

A: Ultrafuse 316L is a professional metal 3D printing material with a specific process to ensure the highest material properties.

Step 1: The part is 3D printed with the metal filament resulting in a “green state” part in which the polymer binder is present.

Step 2: Debinding. The polymer binder is removed leaving the stainless steel material in a “brown state”. At this point, the part is quite fragile.

Step 3: Sintering. The part is baked in a sintering furnace achieving its strength. After sintering your part is the ‘’white state’’

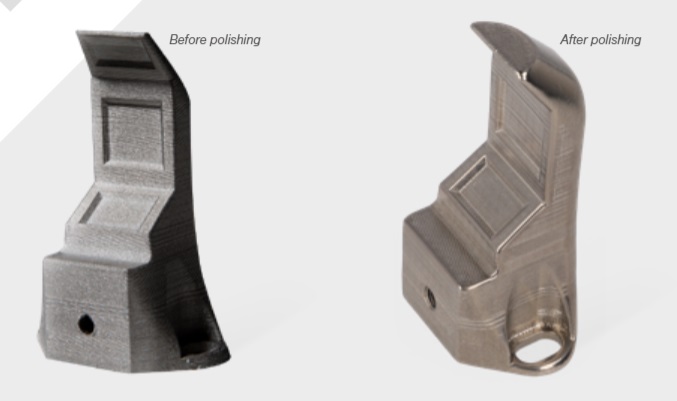

Optional step 4: Mechanical polishing. The part will go through an abrading operation to remove or smooth grinding lines, scratches, mold marks, etc in order to improve the appearance or functionality of the part thanks to a smoother surface.

Q: What are the properties of Ultrafuse 316L?

This filament will produce mechanical parts that will be corrosion resistant, strong and robust. Objects printed with Ultrafuse 316L will perform excellent properties in terms of hardness and strength as they will be almost 100% made out of steel.

Your parts 3D printed in Ultrafuse 316L will also be tough and capable of withstanding repetitive stress. Durability is another property of this 3D printing filament. If you’re looking for a material to produce solid and strong parts, you should consider Ultrafuse 316L for your production.

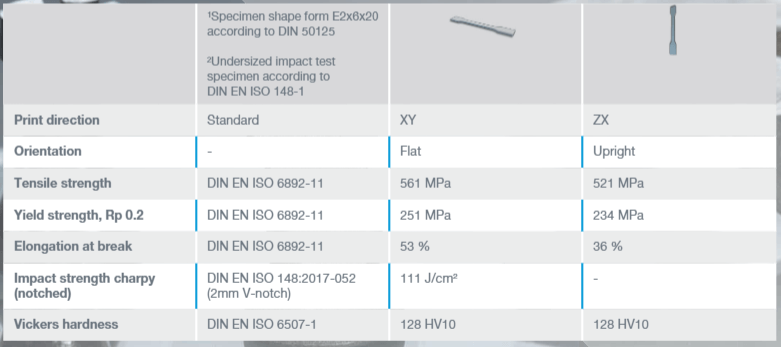

Q: What are the mechanical properties of Ultrafuse 316L?

Q: Why does it stand out compared to traditional FDM filament?

A: First of all, it’s a metal filament, which is not that common. Of course, there are some metal filaments available, but they won’t have such a high ratio. Ultrafuse 316L is composed of 90% Stainless Steel!

Thanks to the post-processing, your parts will come out as nearly 100% solid steel. This is really impressive when it comes to 3D printing filaments. Your part will, of course, have properties of Stainless Steel 316L, it will be exceptionally strong and robust. It will have some great mechanical properties such as corrosion resistance and high ductility.

Q: Where can be this material used?

Ultrafuse 316L is especially interesting for demanding industries such as medical, automotive, or aerospace. It can be used for functional prototypes, mechanical parts, but also pipes, pumps, and valves for chemicals, gas, and oils. Additionally, you can also 3D print non-magnetizable parts or parts for tooling and molds inlays with near-surface cooling.

Q: What are the benefits of Ultrafuse 316L?

The main benefit of Ultrafuse 316L is cost-effectiveness. It’s a great material to produce competitive, but fully functional end-parts. As the parts are 3D printed, you will also save a lot of time if you choose Additive Manufacturing over traditional production methods, especially when it comes to low-volume production.

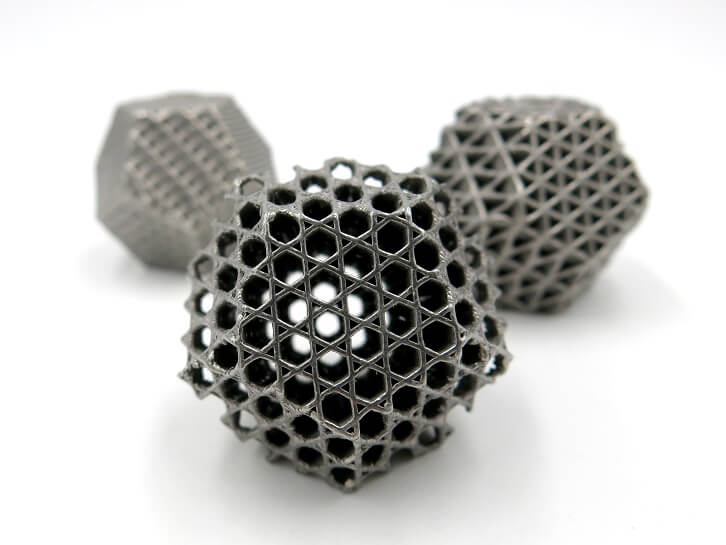

3D printing with Ultrafuse 316L will also give you new design freedom. That applies especially to making your parts lighter. How? Thanks to honeycomb structures and hollowing. With this filament, you can fill your objects with those structures or even hollow it resulting in less material usage which is cheaper and produces lighter parts.

Another benefit of Ultrafuse 316L is its high corrosion resistance. This material is great for applications where toughness and resistance to corrosion are required.

Additionally, when it comes to Ultrafuse 316L, online 3D printing service like Sculpteo will assure your part will be accurate and we will use our expertise to complete the post-processing effectively.

Q: What is the filament diameter of Ultrafuse 316L?

A: This 3D printing filament comes in 1.75 mm and 2.85 mm in diameter.

Q: What is important to keep in mind when designing for Ultrafuse 316L?

Maximum size

The maximum size of your part is 100 x 100 x 100 mm. The maximum size is limited by the size of the printing bed and post-processing machines.

Wall thickness

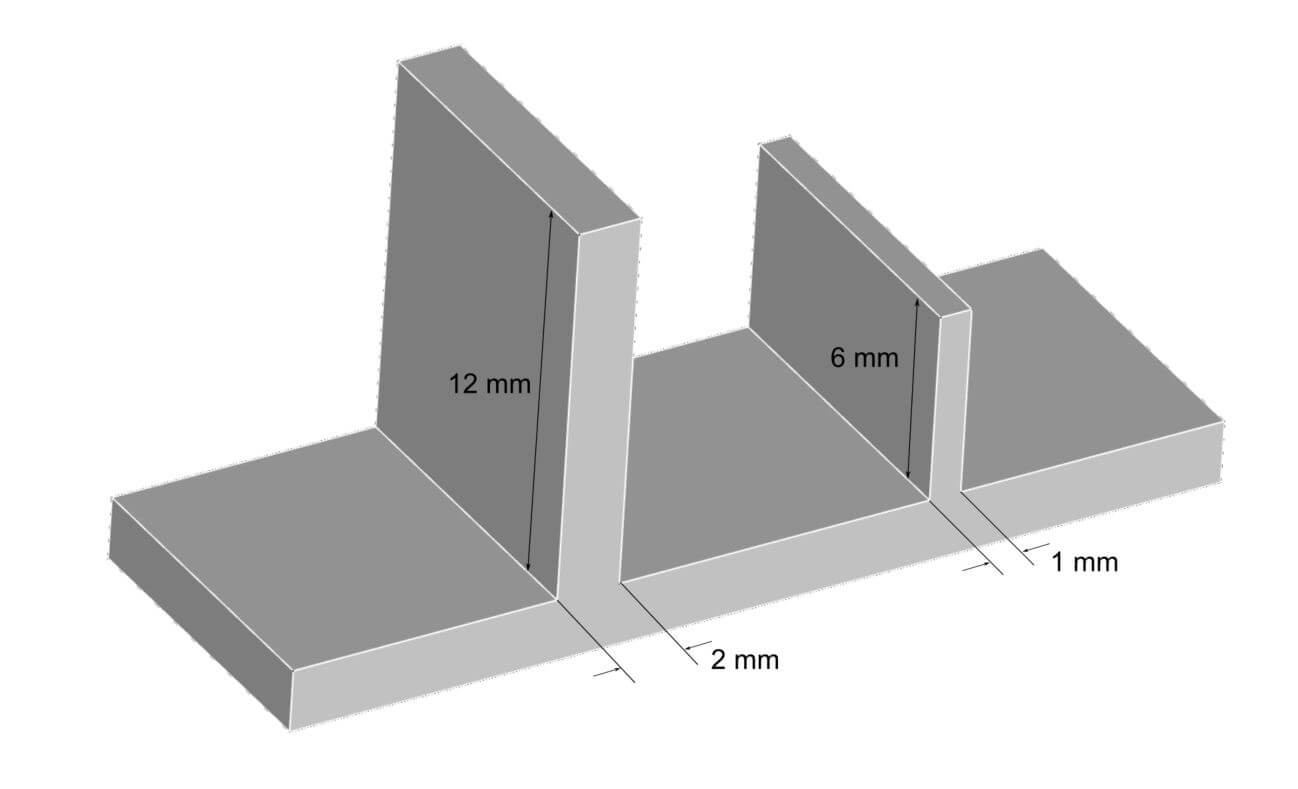

The minimum wall thickness for parts printed with Ultrafuse 316L is 0.8 mm. Thinner walls will collapse.

When it comes to wall thickness, it is also important to keep in mind the ratio. The width to height ratio for Ultrafuse 316L is 1:6. An image below represents those values.

Minimum detail

With Ultrafuse 316L you can achieve a minimum size of details at 0.3 mm.

Supports

If your part has overhangs (a part of the model that extends outwards beyond the previous layer), our 3D printing experts will add support structures in order for 3D printing to be successful. The supports will be removed by our technicians in post-processing.

Q: How long does the 3D printing process take?

As you can see, Ultrafuse 316L is an engineering-grade product and requires technical steps during 3D printing and post-processing, we aim for a 10-day production delay.

Start 3D printing with Ultrafuse 316L today!

Doesn’t Ultrafuse 316L sound like a dream come true for metal 3D printing? With this 3D printing filament, you can save time, totally reinvent your design, improve your parts, and lower your production costs without sacrificing the quality of functionality of your parts.

Are you ready to start 3D printing with Ultrafuse 316L? Join our beta program now! Simply upload your file to our online 3D printing service and enjoy all the benefits of this filament. In case you have 3D printing questions, feel free to contact us.

Get the latest 3D printing news with our Newsletter and Facebook!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook