If you are planning on using 3D printing to manufacture your project, generative design might be an interesting solution to consider. Applications of generative design are numerous, especially when it comes to really advanced and technical projects.

Design for Additive Manufacturing (DfAM) requires specific training and knowledge. Additive manufacturing enables new possibilities, by giving more freedom and flexibility. Innovating by developing interesting structures such as products with internal lattices to optimize the weight of a product is a great advantage offered while using Design for Additive Manufacturing. Designing for this technology creates a new way of thinking and creating objects: this design development is not dependant on the manufacturing constraints of traditional technologies. If you are used to design for other manufacturing techniques, it can be difficult to forget about these constraints while designing: generative design can be a great solution. Free from manufacturing and design constraints, generative design can help to develop innovative parts!

Let’s go through some examples showing the benefits of generative design and additive manufacturing!

Airbus and the cabin partition

Which industry needs to reduce its component’s weight more than the aerospace industry? Indeed, optimizing the weight of airplane components directly impacts CO2 emissions and costs.

This is one of the reasons why the aircraft manufacturer Airbus implemented generative design into its processes to recreate a cabin partition of the A320, its most famous airplane.

Was this trial a success? The answer is yes, according to Airbus, this new part weighs half of the original part, saving 3,180kg of fuel per part. This reduction could lead to a reduction of CO2 emissions by 166 metric tons annually per plane!

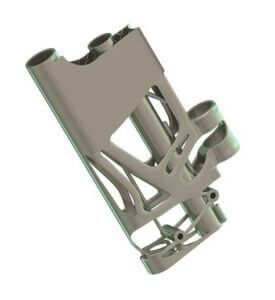

This part has originally been designed for metal additive manufacturing.

Airbus “bionic partition” – https://www.newequipment.com/research-and-development/article/22059780/what-generative-design-is-and-why-its-the-future-of-manufacturing

As we can see with this example, additive manufacturing actually emphasizes the advantages of generative design. Indeed, this manufacturing technique is perfect to bring to life complex and perfectly optimized geometries, impossible to create with other traditional manufacturing methods.

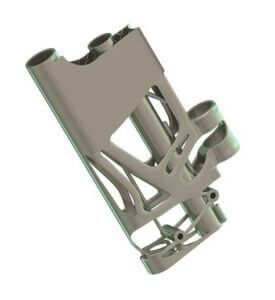

Bugatti

Bugatti, the car manufacturer has tested Siemens NX, the generative design software. They generated a design for their wing control system for the 1,500 PS Chiron super sports car. The part has been printed in titanium and carbon fiber, and this whole process resulted in an optimized assembly, with a weight reduction of more than 50%.

Bugatti

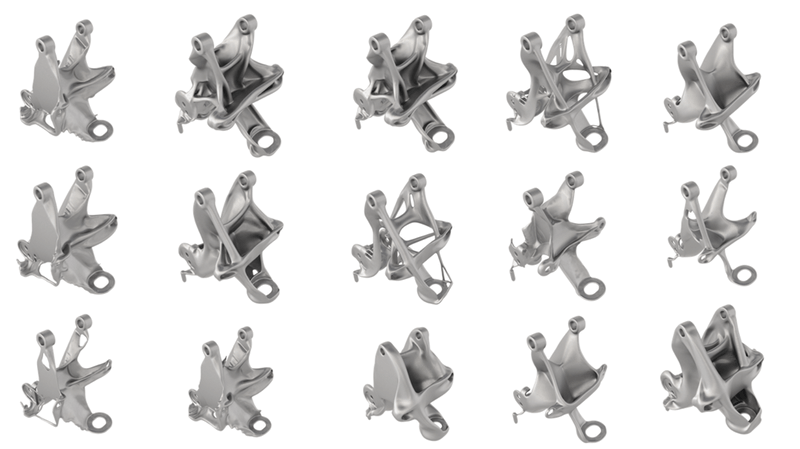

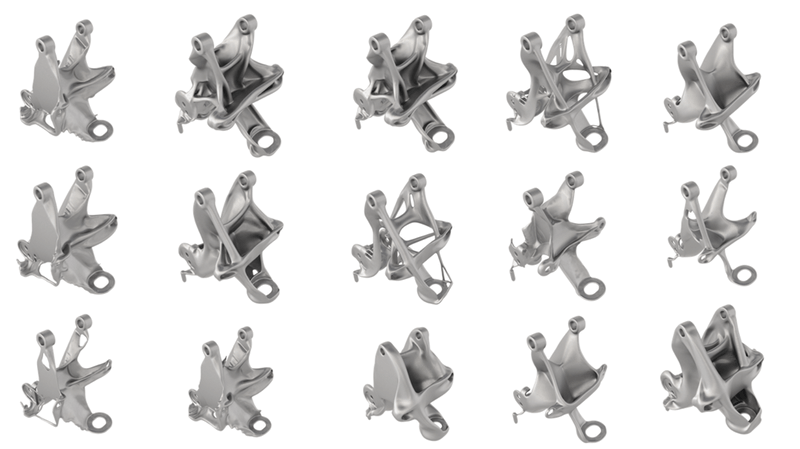

General Motors and the seat bracket

Using Autodesk, the car manufacturer General Motors also experienced the potential of generative design to create a seat bracket. The 150 designs generated by Autodesk were actually 40% lighter and 20% stronger than the bracket they are currently using!

General Motors

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook