Capacidades

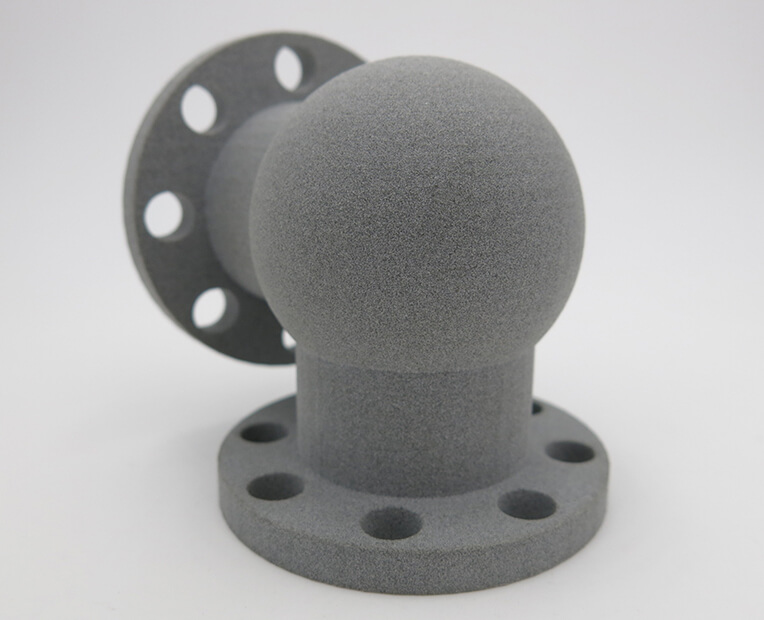

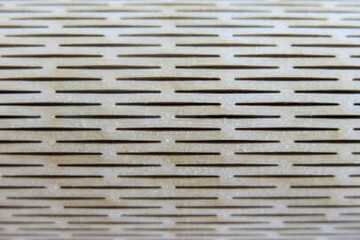

Con más de 75 combinaciones de materiales y acabados de impresión 3D, garantizamos la más alta calidad profesional de cada una de nuestras impresoras 3D y técnicas de impresión de última generación.

- ISO 9001

- Entrega rápida

- Carga segura de archivos

Conéctate con Google

Conéctate con Google Conéctate con Facebook

Conéctate con Facebook