Let us introduce Ultracur3D® RG 3280, BASF’s first composite material addition to their rigid product line. This material is a ceramic filled resin, especially engineered to possess exceptional stiffness, unrivaled heat resistance, and remarkable electrical insulation properties, offering a new level of versatility, reliability and performance in the realm of 3D printed resins.

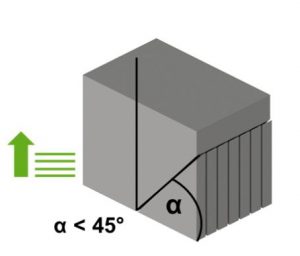

Ultracur3D® RG 3280 will deliver particularly startling results as an extremely stiff and heat resistant material, ensuring structural integrity and dimensional stability, even in the most demanding applications. With a Young’s modulus of 10 000 MPa, exceeding most traditional resins, this innovative material can withstand substantial forces without yielding, providing excellent load-bearing capabilities.

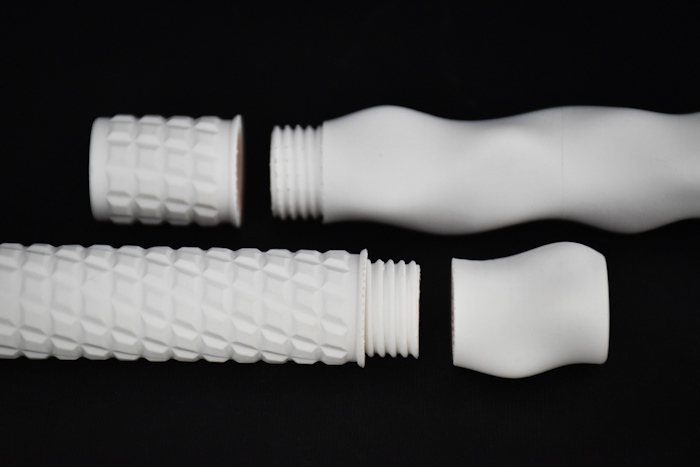

As a result of this extraordinary stiffness, Ultracur3D® RG 3280 will prove especially valuable to design intricate mechanical components, as well as robust structural parts.

Another impressive advantage of this resin is its outstanding heat resistance. In fact, benefitting from its ceramic particles’ great temperature resilience, Ultracur3D® RG 3280 is capable of withstanding temperatures exceeding 280 degrees Celsius. This characteristic makes it an enticing choice for applications in industries that encounter extreme thermal environments, such as aerospace, automotive or electronics.

In addition to these remarkable qualities regarding heat resistance and stiffness, Ultracur3D® RG 3280 possesses notable electrical insulation properties. Unaffected by electrical currents and exhibiting high dielectric strength, this resin offers a superior level of protection against electrical conductivity, making it an ideal choice for applications requiring insulation and isolation of electrical components.

Ultimately, Ultracur3D® RG 3280 provides exceptional rigidity, resistance to heat, and reliability, with a distinctive cold touch and smooth surface finish.

Lastly, it is worth mentioning that Ultracur3D® RG 3280 has been engineered to facilitate high precision, dimensional accuracy and fine resolution. In particular, this material would be particularly suited for the production of molds. If you’d like to produce molds, please contact us so that we can guide you through the best practices.

This new formulation is an interesting addition to the continuously evolving range of 3D printing materials. Providing great freedom of design and versatility, while also being extremely rigid and resistant to heat, this is a material you don’t want to miss out on!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook