4 Things 3D Printing Power-Users Do…

Posted By Sculpteo on Jun 9, 2015 | 0 comments

One of the lessons we learned from our State of 3D Printing report is the existence of a core group of users that have developed super powers in their organizations thanks to 3D Printing. We named them the “Society of the 3D Printing Power-Users”. Are you excited to enter it? Or are you curious to know if you’re already a member? Here are 4 things that you need to do to be part of it.

With more than 1,200 respondents, the State of 3D Printing report is the largest study done on the users of this technology. Among them, we have statistically detected a core population with similar behavior regarding expenses, usage and general opinion about the benefits of the technology. They represent about 18% of the respondents.

1. Power-users never get their 3D files on external libraries

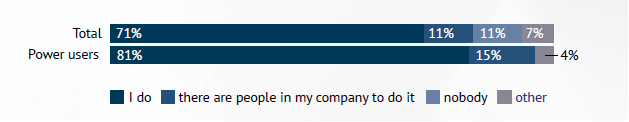

Power-Users are deeply involved in the creation of their 3D designs. 81% state that they make their own files and 15% said that someone was doing it for them. If you’d like increase your skills, first assess your 3D design level and think about how an intensive training program could help you level-up!

2. Power-users are using 3D-printing for almost everything

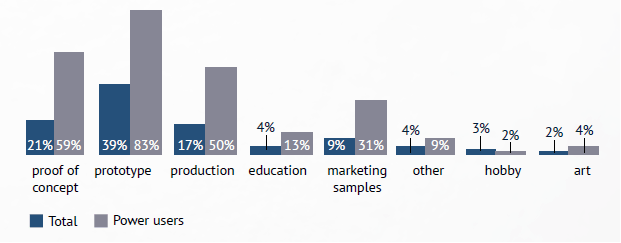

Restricting the benefits of 3D Printing to producing prototypes is the opposite the Power-Users attitude. On the contrary, they are over-using 3D printing. 63% declare that 3D Printing permeate most of their programs (when whole respondents are only at 23%). Focusing on the purpose of the 3D print is equally important: 50% are using 3D Printing for production; 13% for educational purpose, and 31% for marketing samples. To become a power user, you need to think 3D-Printing GLOBALLY.

3. Power-users are using 3D printed Metals

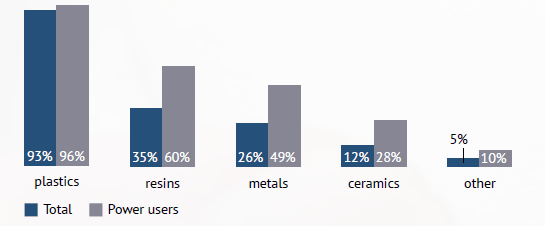

If you’re looking for the type of materials you should use, start with plastic, but make looking into other materials—resin and metals—a priority. 60% of the Power-users say that they also 3D print in resin and 50% have also used metals.

4. Power-users anticipate a massive increase in the use of additive manufacturing

Regardless of the size of your team or budget, few of us can afford to be inefficient. Spending time and money implementing flawed programs is the very definition of inefficiency. What are some of the challenges you should anticipate? Here are a few items to consider. Start by developing your product, but don’t overlook the benefits associated with production—these are the areas where power users intend to take the lead over their competitors. For 1/5 of them, increased flexibility and lower tool costs are priorities.

You can get the whole results in Sculpteo State of 3D Printing report or start to be a Power-User directly on sculpteo.com

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook