Maximize your ROI from 3D printing

Posted By Claire Chabaud on Jun 22, 2016 | 0 comments

Most companies are aware that implementing 3D printing in their strategy is key. But how can they do it effectively? What are the main aspects to consider when looking for such a change in your production process? Is this investment really worth it? If you are asking yourself these questions, then this article is tailor-made for you. Based on the result of our State of 3D printing study, we are going to define 5 ways to ensure that you maximize your ROI from 3D printing.

Maximize your ROI from 3D printing by accelerating your product development

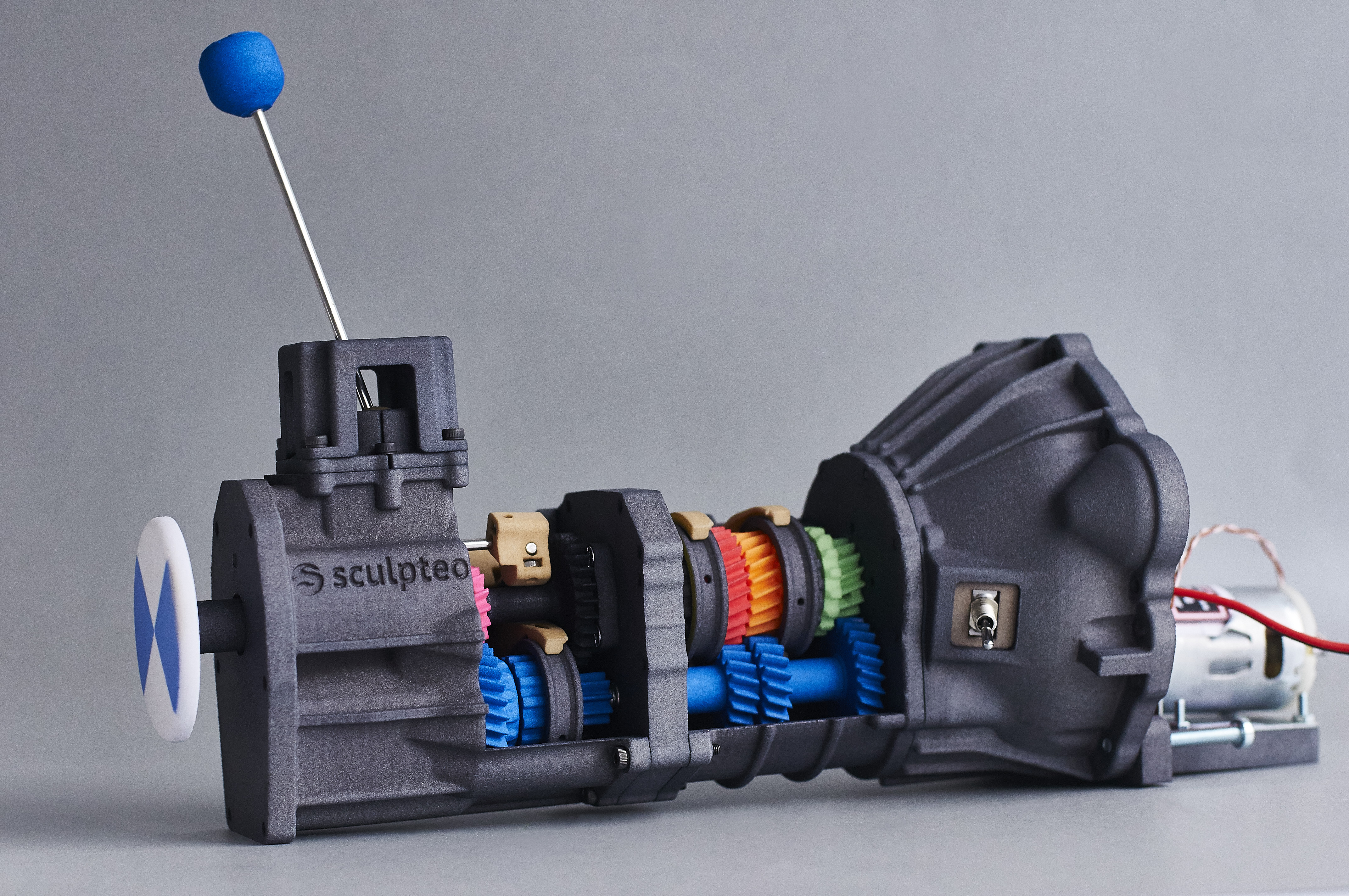

47% of professional respondents pick the acceleration of product development as one of their top priorities. Indeed, although 3D printing still lacks some things to compete with the current state of manufacturing technology to create a final product, its status as a prototyping technology is matchless. It has game-changing qualities in prototyping, such as allowing quick iterative steps and being highly responsive to making changes and adapting your model, with a cost that is significantly below the market price.

This technology is very adapted for start-ups, which need to quickly develop an MVP to convince an investor, test their market, or sell limited series without engaging a high WCR. For settled companies, 3D printing is useful in Marketing and Product development departments. It helps the team concretely conceive the product in their minds. The same way it does for start-ups, 3D printing is a precious tool for entrepreneurs who want to innovate within the company.

How can you implement it in your company?

First, you need to have someone with effective CAD skills. Then, you can either invest in a 3D printer or use a 3D printing service. This choice will mainly depend on your budget and the properties and quality of the print you need. To help you make a choice, this article might help you figure out which option is more suited for you. When using 3D printing in a prototyping step, the ideal is to consider an iterative period of 9 days: 2 days to make the design, 4-5 days to receive it printed if you use an online 3D printing service, and 2-3 days to make a change and update the design. If you want to have a better idea of implementation, Blendbow and its 600-piece cocktail machine is a telltale example of production development with 3D printing.

Maximize your ROI from 3D printing by creating a customized production limited series

33% of the professionals answering the State of 3D printing report consider customized production and limited series as one of the main benefits of 3D printing.

One of the main benefits of 3D printing is whether you order the same part a hundred times, or a hundred different customized parts, the action would take the same amount of time and have the same cost. This is one of the main reasons this technology is very adapted for mass-customization. At Sculpteo, we created some tools as batch control to help you get some scale economies anyway. Nevertheless, compared to the traditional manufacturing process, the cost of customization is relatively low. Mass-customization is ideal for limited series, for example, when you want to create a special communication event or collection. One of our favorite customer stories about this is when SKODA used 3D printed customized cars to attract customers to their shop to try their brand new car. It was an uncommon and successful campaign. This strategy helps you make your customer more attached to your brand, as well as show that you can create a made-to-measure product/service.

Maximize your ROI from 3D printing by increasing production flexibility

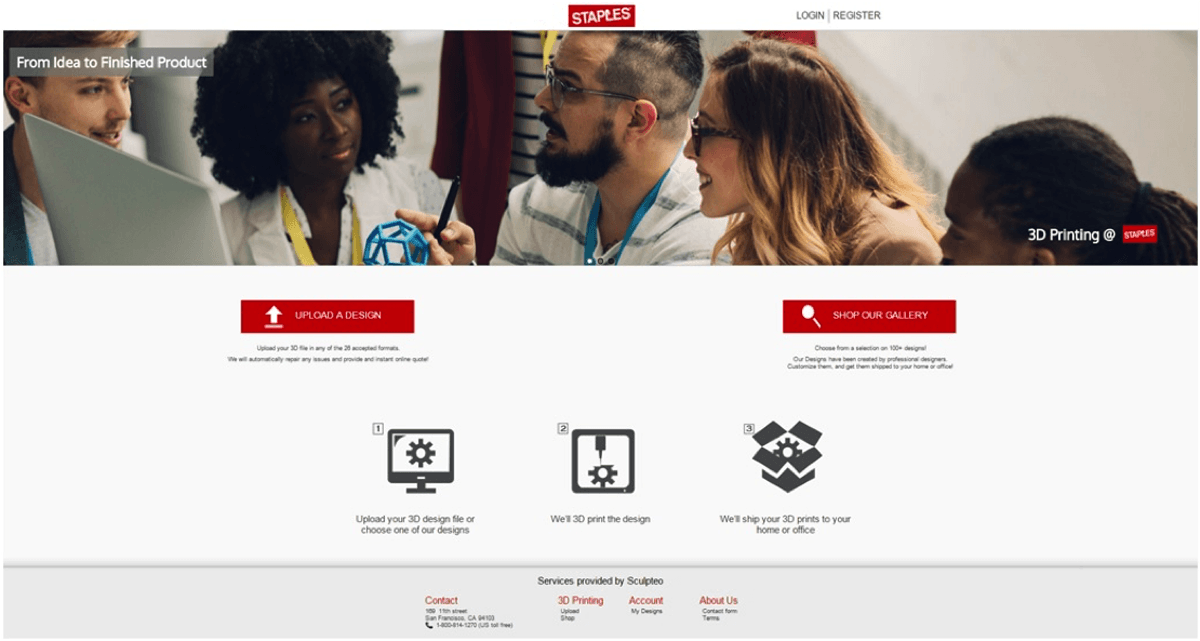

20% of professionals consider 3D printing as a real asset to increase their production flexibility. This figure might appear disappointing, but what is important is its evolution over time. For 2020, 27% of professionals state that 3D printing will be a key factor to improve flexibility. This figure highlights the fact that the technology is not yet implemented (and probably not mastered) enough as a tool for flexibility, but it is expected to gain ground in the coming years. By using 3D printing as a means of production, you can access the just-in-time manufacturing process with 0 stock. There’s no need for you to pre-produce your next delivery; just wait for it and order it. Also, you can easily adapt the quantity you need, on time. Your production can be fully flexible to your customers’ evolution. If you want to fully outsource this process, sometimes our white-brand can be the best-suited solution for your business. For example, after integrating our service to Staples, we directly receive the order from their clients, and then 3D print and deliver them. Thanks to our online 3D printing service, we can be your next digital factory and help you make the most of your production flexibility.

Maximize your ROI from 3D printing by optimizing demo product expenses

15% of the professionals are expecting to use 3D printing as a demo product to decrease its cost. The customer buys what he sees. For this very reason, the more your demo product is looking like a finish product, the more you’ll get people to purchase your item. The main problem with creating the demo product is the cost induced by the fact that you only created a very limited series and in the majority of cases, the financial means are limited. With 3D printing, your costs are handled, and you can obtain a lookalike final product. For example, with a finish like the smoothing beautifier, you can get the same smooth surface as with an injection-molded plastic. Thus, more than the cost, you can also optimize the functional and surface aspect of your product like never before. This represents an effective way to get a significant return on your investment.

Maximize your ROI from 3D printing by decreasing your tooling investment

13% of the professionals feel that 3D printing is helping decrease tooling investment. The reason is practical. With traditional manufacturing production methods, you need to create specific tooling to produce each product. This cost is a real entry barrier for limited and medium series. But with 3D printing, there’s no need to create any mold or tool to create the shape of your product – just a 3D file! The price you’ll pay is just the printing one and decrease in case of series with our batch control tool for instance. Depending on the size of your series, one of this manufacturing processes will be better suited for your production. If you want to get all the data and specific details to compare these two manufacturing processes, you can take a look at our dedicated guide.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook