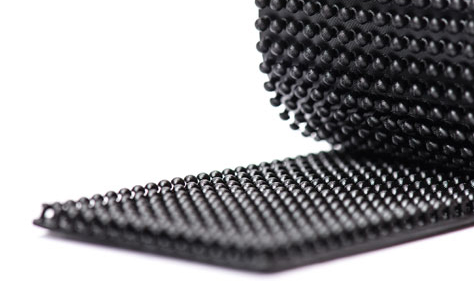

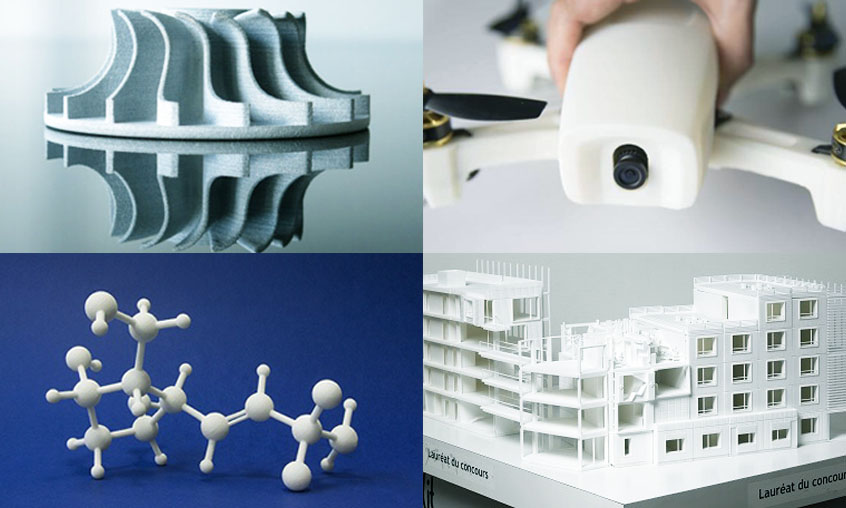

Have you ever created a 3D model that could not be 3D printed because of its fragility? Calculating the minimum wall thickness is one of the most important steps when preparing a 3D model for 3D Printing. In this blogpost, we prepared for you some ti...

Read More

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook