3D printing and archeological challenges!

Posted By Lucie Gaget on Jan 9, 2019 | 0 comments

Here is a project developed by an archeology team at the University of California, in Los Angeles: they decided to help to reconstruct the ruins of Tiwanaku (AD 500 – 950). 3D modeling and 3D printing have been used to help this Unesco World Heritage Site located in Bolivia. 3D printing and archeological projects are making a great couple!

Let’s see how this archeology team succeeded to reconstruct this temple, and discover how 3D printing can be useful for these kinds of archeological projects.

Reconstructing and preserving cultural heritage

Ruins in Bolivia

The Tiwanaku is a Pre-Columbian civilization from Bolivia, known for its monumental architecture. The archeologist Alexei Vranich decided to use a Lego-like system in order to reconstruct Pumapunku, a temple, by using 3D printed parts. Indeed as it is impossible to put all these existing parts back together, we didn’t know what this temple looked like.

The Pumapunku temple is formed of finely cut sandstone slabs and blocks of andesite. There are 150 scattered blocks, but none of them are in their original place. As some of these surviving stones are too heavy to move, Vranich decided to create exact replicas of these stones. In this case, 3D printing appeared to be one of the most convenient manufacturing methods.

Via Heritage Science

There have been some reconstruction attempts in the past few years, but they all failed. However, based on the existing measurements and previous studies, the team have been able to start a 3D printed reconstruction process. The goal of this 3D printing project is to finally have a good representation of what this temple was; and for archeologists, it is a way to get something they can manipulate to study it! The models were scaled to 4% of the original site.

It is not the only monument or cultural site that has been 3D printed. An arch destroyed by ISIS, has already been recreated using additive manufacturing. This application of 3D printing could have a huge impact on our cultural heritage, it could help to preserve numerous monuments.

How did they proceed?

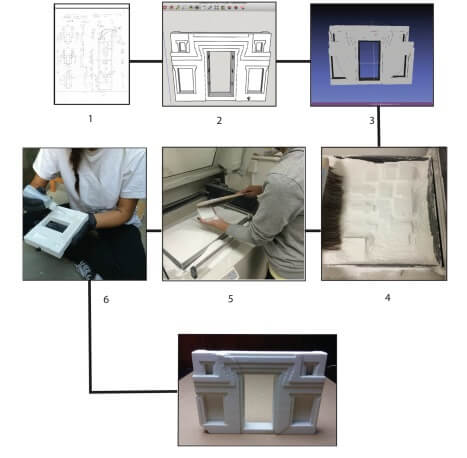

They have been able to go through the previous notes and documentation, so they were not completely starting from scratch. Data collected over 150 years helped the team of archeologists. Indeed, these data have been translated into 3D information, and CAD designs of the Pumapunku temple have been made, using Sketchup. This 3D modeling software is particularly great for architectural projects! Go check our top of the best 3D modeling software for architecture right now.

Here are the stages of 3D printing a Pumapunku gate:

via Heritage Science

Could 3D scanning have helped in this case? No, because of the underlying geometry of the temple, it would have been too laborious. However, 3D scanning can still be used for the preservation of cultural heritage.

For early versions, they used an FDM/FFF printers, and then a powder-based printer was used.

Then to recreate Pumapunku, archeologists had to manipulate complex geometries: For this advanced project, they had to assemble all the models by themselves. That assembly of 3D printed archeological models allows a great visualization, but also allows them to get new geometric manipulation skills which could help in archeological training in the future.

Additive manufacturing could not only be useful for the training of archeologists, but it could also be used for education in a lot of different industries, like healthcare, or any kind of job where you need to manipulate delicate objects.

Why is 3D printing the perfect solution for these kinds of projects?

When additive manufacturing appears to be the best process

Thanks to the use of 3D programs, it becomes easier to build projects like this one. Indeed, it appears to be a perfect solution to get a great visualization and to make all the 3D printed iterations and all the 3D modifications or simulations using a CAD program.

3D printing allows to get accurate objects, but also to work on really complex geometries.

3D printing for reconstruction, but also for conservation?

Indeed, before having to reconstruct artifacts and structures, we could keep data and reproductions made using the 3D printing technology. It could really be useful to keep track of the fragile objects.

For example, we saw that 3D printing or 3D scans could be used by museums to reproduce artifacts and precious collections. Want to know how additive manufacturing could help museum conservation? Read our blog post about 3D printing for museums!

3D printing for archeology and reconstruction has quite a bright future. Indeed, this project is proof that is it possible to recreate monuments using this cutting-edge technology!

For more 3D printing news, don’t hesitate to subscribe to our newsletter!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook