Medical Industry

Discover how additive manufacturing can be a game-changer for your medical project!

- Innovation

- Adaptability

- Scalability

How can 3D printing benefit the medical industry ?

Login

If you have any trouble logging in to your account, contact us.

Sign Up

To start 3D printing or Laser Cutting, you'll need to create an account here. Once done, you'll be able to upload your files and get live quotes of yours parts

Already have an account? Log In

Discover how additive manufacturing can be a game-changer for your medical project!

Home » 3D Learning Hub » 3D Printing Applications » Ultimate Guide To: Medical 3D Printing Applications

Surgeons, students, dentists, do you know that 3D printing is becoming one of the main tools of the medical industry? As a 3D printing service, we regularly see new medical projects developed using plastic, resin or metal 3D printing. 3D printing in medicine improves the daily work of all professionals from the medical sector, allowing them to save more and more lives every day. From the creation of medical tools and equipment to custom-made prosthetics, let’s take an in-depth look at how 3D printing is impacting the medical industry.

Are you working in the medical field? Are you looking for a medical manufacturer and considering additive manufacturing? We will also start thinking about your project: What are the exact benefits of 3D printing for your project? Find it out!

If you are willing to use 3D printing technology, here is the first thing you need to do: Start choosing a 3D modeling software. In order to use additive manufacturing, you have to get a 3D model of the thing you want to print. A prosthesis, an implant, a tool, your project needs to get its three-dimensional representation before being printed.

The use of 3D software is full of benefits. Indeed, it will offer you the opportunity to create your project from scratch, allowing you to make a device that entirely fits your needs. Moreover, using modeling software will help you during your prototyping process.

Indeed, you will be able to modify your 3D model whenever you need to. If you are developing your project creating quick iterations using 3D software and 3D printing will be a huge advantage and will help you save time.

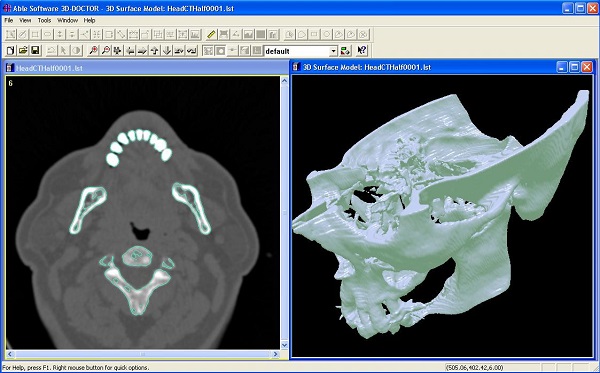

Source: http://www.ablesw.com/3d-doctor/tutor.html

While using a medical 3D modeling program, you can easily expand your possibilities, and try new things. When you get started, you need to pay attention to a few things.

First, there are different 3D modeling software for the medical industry and to make the most of 3D, you need to choose the right one. It will depend on your project. Do you need to 3D print? Or do you need a better and practical visualization? Maybe both? You have to ask yourself the right questions before making your choice.

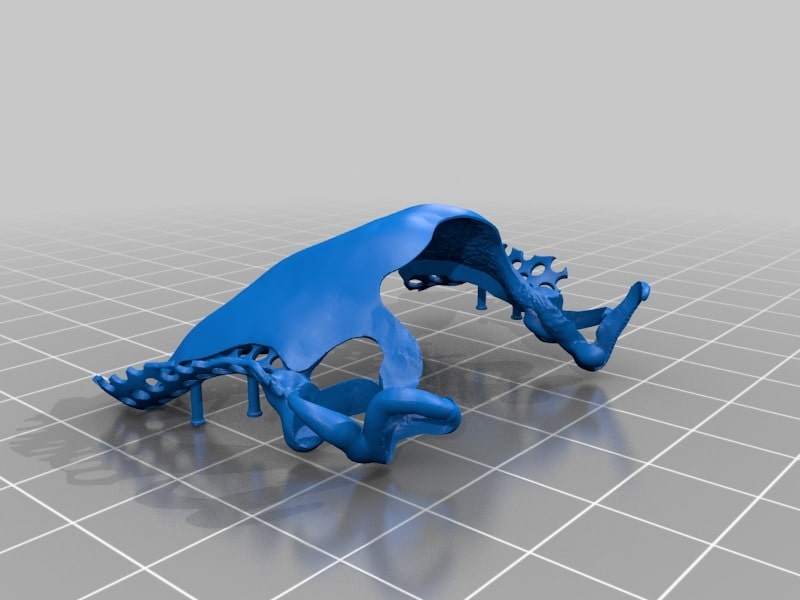

Source: Thingiverse

Secondly, before using a 3D modeling software you have to check the format of the file you want to import. This is an important thing for medical applications. Indeed, most of the time, medical imaging scans are in a DICOM format, which is not a format supported by regular modeling software. But it doesn’t mean that you can’t use standard modeling software for your medical application. You just have to take into account that you need a software solution allowing you to modify the format first! 3D scanning is also enabling medical applications, no doubt that portable 3D scanners will soon be used by all hospitals.

3D printing in medicine is becoming quite helpful in many aspects. For example, we can see that more and more from the customers of our online 3D printing service, to create custom made medical tools, fully adapted to their job, and to their specific needs. Indeed, using 3D printing is particularly helpful when it comes to tools, it makes it possible to make one or several tools.

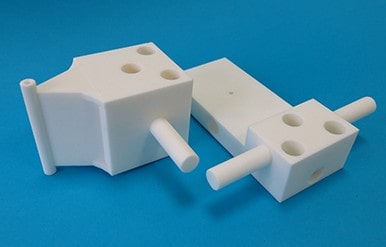

Marc Soubeyrand is a surgeon using our printing service to create its own tools. By compiling the patient medical imaging (in this case from CT scans) to turn them into a proper 3D file. The 3D printed parts are then used to guide the surgeon during the surgery and make sure the implants are positioned perfectly. These surgical guides are then perfectly adapted to the surgery performed by the doctor. He is more prepared, and more efficient, able to be 100% focused on the patient.

Ancillary tool 3D printed by Sculpteo for an orthopedic surgery

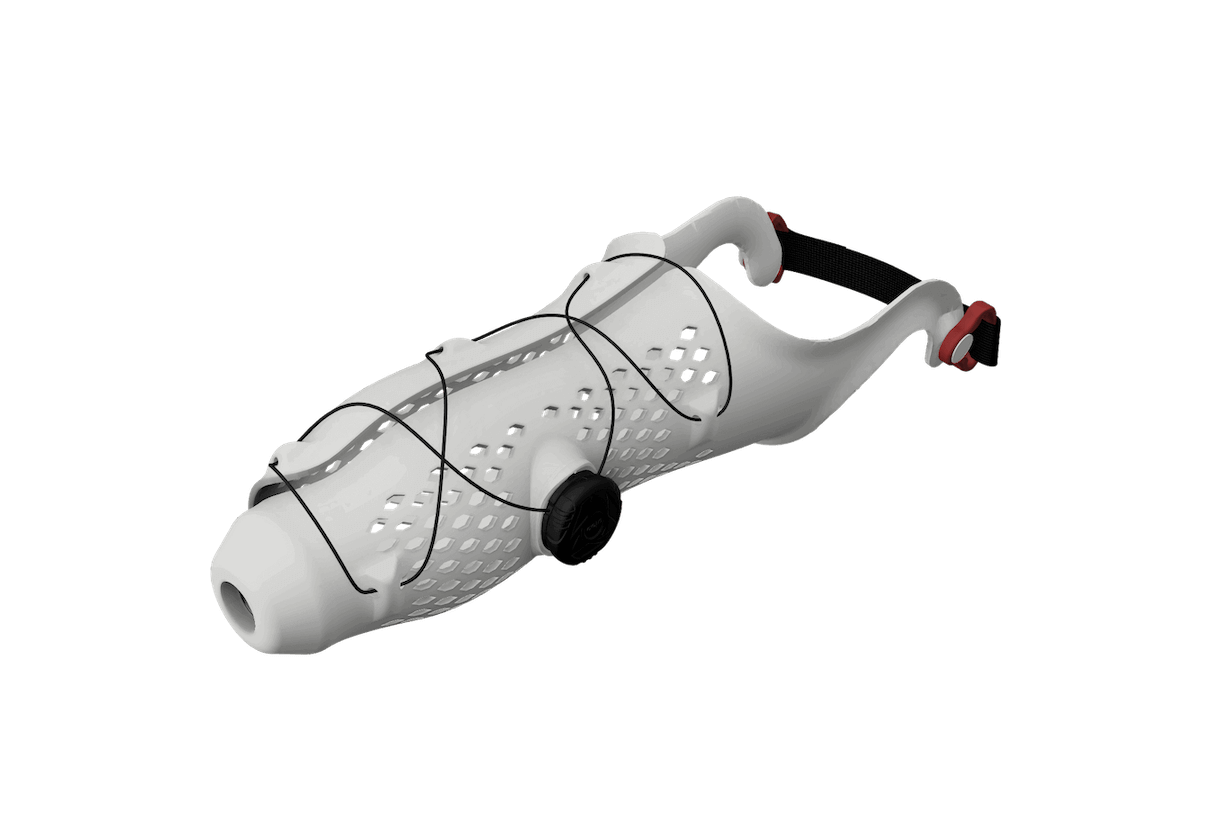

Macu4 turns to the innovative potential of AM to create arm prostheses that are affordable, lightweight, and versatile.

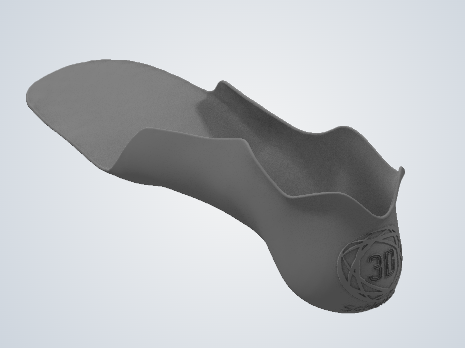

The integration of 3D construction has opened up completely new possibilities for the production of orthopedic aids for Schlather GmbH. With 3D printing and PP material, Schlather developed a Dynamic Foot Orthosis (DFO) to correct various deformities such as a clubfoot or extremely high arches.

The challenges for Daniel Robert Orthopedics were that every design had to be completely individualized and fitted for each patient’s unique needs and that the production quality had to be consistent and repeatable.

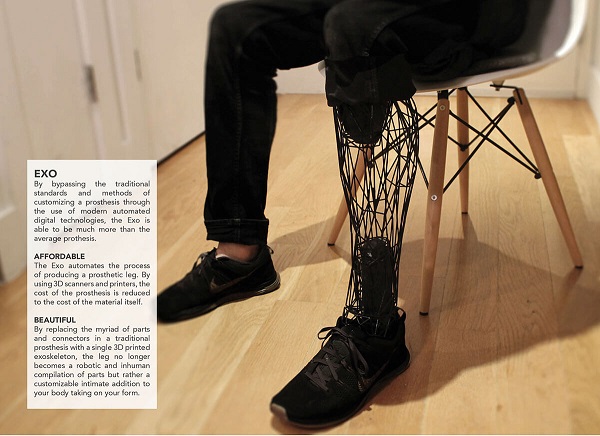

Customization can be used to create tools, but not only. 3D printing is making it possible to create perfectly adapted devices like 3D printed casts, or even further: 3D printed prosthetics and implants for any patient. Additive manufacturing is now a way to create hands, arms, and legs, helping amputees to live a normal life.

leg prosthetics – https://www.behance.net/gallery/20696469/Exo-Prosthetic-Leg

But why is this technology a better way to create prosthesis? As you may know, a traditional prosthesis is expensive and not necessarily adapted to the patient. A 3D printed prosthesis has a lower cost and can be fully adapted to the morphology of the patients, to their habits, and their disability thanks to 3D scanning and 3D modeling.

Video 3D printed hand prosthesis:

Start using 3D printing for your prosthesis projects! Even more impressive, some researchers have been able to create a 3D printed artificial cornea. 3D printed eyes are not even that far today.

Additive manufacturing is saving lives and can help for bone reconstruction. This technology helps to make custom products, that can be tailored for each patient, outside and inside their bodies. For example, additive manufacturing is offering new possibilities for jaw reconstruction!

www.bbc.com/news/technology-16907104

In the Netherlands, an 83-year-old woman had a jaw reconstruction thanks to 3D printing. Her 3D printed jawbone has been made with titanium powder and a bioceramic coating. A special dental bridge has been added to the jawbone, in order to implant new teeth to the patient. Due to her age, doctors chose to use this method, saying that it was less risky than the traditional procedure!

3D printed knees are also becoming a solution. Two different things have actually been tested: 3D printed synthetic cartilage for knee replacement and using 3D printing for knee realignment.

Regarding the manufacturing of cartilage, the idea was to make a material that could match human cartilage has been developed by scientists in the US, at Duke University in North Carolina. The goal was to create something that almost has the same properties: a certain strength, good elasticity, and shock absorption. This has been made possible by mixing two types of hydrogels, and some clay, to make it printable.

3D printed knee implant companies such as Conformis are also developing the use of 3D printing to create implants, using a CT scan of each patient. Conformis knee implants are made possible by 3D printing and are totally making the most of the custom-made aspect. This way, the knee implant entirely respects the morphology and the needs of the patient.

https://www.healthtechevent.com/health-care/global-knee-implant-market-revolutionised-conformis-3d-printed-knee-replacements/

A company Mat(t)isse and doctors from the CHU of Lille have developed a new method that benefits to women who are in need of breast prosthesis. Instead of using silicone implants, Mat(t)isse and the three doctors used other breast reconstruction techniques: the fat transfer technique or lipofilling.

However, the problem when using this method is that if you inject too much fat into the breast area, it may be reabsorbed by the body over time, and the patient has to undergo another surgical procedure.

In order to avoid the fat being absorbed by the body, they created a 3D printed shell with a lace shape. This prosthesis is entirely bio-resorbable which means it would be absorbed by the body like stitches. Reconstruction is natural, the prosthesis can be customized and the patient no longer needs to re-do the surgery.

More than bone reconstruction, 3D printing in the medical field is starting to show some great improvement on organ 3D printing. Indeed, this 3D technology also showed that it was possible to print devices working exactly like our living organs. It could become a real solution to face the lack of organ donors!

Recently the first proof of concept of a 3D printed lung has been developed by Jordan Miller, assistant professor of bioengineering at Rice’s Brown School of Engineering and his team. This lung has been made using a complex structure.

The 3D printing process used to create this outstanding proof of concept is Stereolithography apparatus for tissue engineering. Using light for a digital projector, this bioprinting process creates hydrogels layer by layer.

Here is a video of the functional 3D printed lung:

This new device is mimicking and replicating a real human organ, it is actually a really promising project, announcing a new great development in terms of organ donation.

The same scenario happened for an artificial 3D printed heart, Scientists from the ETH Zurich in Switzerland created an artificial heart which can beat just like a real heart, during half an hour. This soft artificial heart, using a transplantable and soft material is already a big success. This device will surely be improved in the upcoming year, and start to be a good alternative for patients in need of a brand new functional heart.

3D printing is also impacting the dental industry by avoiding time-consuming processes and saving money, benefits of 3D printers are numerous.

These last few years, additive manufacturing offered brand new possibilities, from 3D printed braces to 3D printed dentures and crowns, everything is 3D printable! This technology is now allowing to get implants faster by avoiding the whole molding process. The dentist can take all the steps by himself, and save precious time for his patients.

Training surgeons with 3D printing… How is it possible? It is becoming more and more common. By using CT scans we know that doctors are now able to use 3D software to get some good visualization and try some simulations to train before the surgery. But thanks to additive manufacturing, it is now possible to go further and get real anatomical models!

Some surgeons are now using these CT scans to create 3D models and print them, in order to train on the real replica of the heart, spine, or any part of the patient. This a way to get a better view of the problem, and actually train on it.

It is particularly useful for complex surgery. Indeed, thanks to this process, some surgeons affirm that they can reduce surgery time because they know exactly how to proceed! They are more efficient.

Axial3D

That is exactly what happened in the Belfast City Hospital, in Northern Ireland when a medical team decided to 3D print a kidney. William Fenton, the father of the little patient Pauline Fenton, was compatible to give his kidney, but as he didn’t have the same blood group, it was adding some complexity to the surgery.

They decided to 3D print a replica of the donor’s kidney in order to rehearse this complex complete excision. Gestures have to be really precise to be efficient. By using this technique, surgeons rehearsed the whole surgery to be ready, by taking into account all the possible complications. 3D printing can help to train for all kinds of surgeries.

From dentists to orthopedic surgeons: there is necessarily a way to use this cutting-edge technology to help you.

These 3D printed models can also be used to train students, or to explain its problem to the patient! This way the patient can get a better understanding of what is actually happening and how the doctors will solve the problem.

http://www.3ders.org/articles/20180518-surgeons-use-3d-printing-for-two-year-olds-life-saving-complex-kidney-transplant.html

Additive manufacturing is also helping to find new solutions, and try new medical solutions. More and more researchers are now interested in 3D printing technology. This technology is making it easier to make iterations than with injection molding, for example.

Trying new things at a lower cost has never been easier. And there is still room for improvement in the medical industry, new materials and new devices are constantly developed by teams of researchers.

From 3D printed sponges to cure cancer to adaptive aids to help patients with arthritis, additive manufacturing is becoming a real revolution in the medical sector.

Do you know that 3D printing tissues and organs are actually becoming possible? This is called bioprinting. But how does bioprinting it work?

The process of bioprinting is not as fast as 3D printing: The bioprinting process uses bio-inks, a material allowing the adhesion and proliferation of living cells. Maturation is part of the process for bioprinting, because cells have to grow and proliferate, this can’t be done instantly. Bio-inks are hydrogel biomaterials, providing support to the cell while they produce their own natural extracellular matrix.

Actually, the first 3D printed heart with human tissue has been developed recently. How is it possible, you might ask… Firstly a biopsy on the patient’s fatty tissue has to be completed. The sample was then separated into cellular and acellular. Next step, the cells were reprogrammed to perform as pluripotent stem cells.

Those cells were mixed with other biomaterials such as collagen to produce bio-ink. It’s important to mention that the bio-ink itself is outstanding as it eliminates the risk of organ rejection. The heart was then 3D printed it a support bath.

Check out this quick video of the 3D printing process:

There is still some improvement to make, now the 3D printed heart with human tissue is too small for a human. But we can see that we are at the beginning of a true medical revolution.

This bioprinting thing is not only helping to print organs, it is also helping to create prosthetic limbs. The main advantages of 3D bioprinting are that it helps to face the lack of organ donors, and it also avoids risks of rejections as these organs or body parts are made using patient’s cells.

It is possible to create real body parts thanks to additive manufacturing. In India, a recent successful experiment has also been made with bioprinted ears. The process is the same, scientists from the SRM University and the SIMS Hospital has to create it with existing stem cells. These cells grew in a solution for three weeks. Then the result has been used to print an ear.

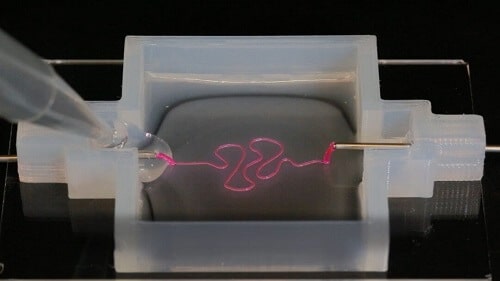

We saw that it was possible to print kidneys in order to train for surgery, but some scientists went even further with the 3D printed kidney project. Indeed, scientists of the Jennifer Lewis lab developed intricate tubes working on real kidneys. For the first time, scientists created artificial kidney tissue, working like real ones thanks to living cells. It is quite a revolution!

https://www.technologyreview.com/s/602691/3-d-printed-kidney-parts-just-got-closer-to-reality/

You may not know it, but additive manufacturing can help treatment testing. But how exactly? Using bioprinting will enable to print real human skin, which would make it possible to test new drugs without having to test it on animals, for example.

Shalini Guleria, a student from the University of Waikato in New Zealand took particular interest in breast cancer patients and bioprinting. How can we combine medical 3D printing and breast cancer treatments?

Here is her idea: 3D bioprinting and the use of natural, human-safe materials are not new, so she used this technology to work with cancerous cells. Here is the first step: the cells would be extracted from the patient, then implemented in hydrogel and 3D printed in the size of a fist in order to imitate a tumor.

After this whole process, the printed model of a tumor then could be tested for different drugs, the point will be to eliminate risky and unsuccessful drug testing on patients.

https://www.3dnatives.com/en/bio-printing-tumour-treatment-cancer-180920184/

https://www.3dnatives.com/en/bio-printing-tumour-treatment-cancer-180920184/These medical applications of 3D printing clearly show that everything is possible for health care, to improve patient care. Your medical project can also be 3D printed! From plastic to metal 3D printing, our online 3D printing service helps you to give life to all kinds of devices you might need: medical tools, medical models for you or for your students, etc. we can help you improve your daily work! Take a look at our wide-range of 3D printing materials and discover how you can improve your medical equipment. With materials adapted to skin contact such as Ultrasint® PA11 & MJF PA11 it possible to create made-to-measure medical devices such as orthopedic parts.

You can start making the most of our professional 3D printers right now. Make educational models for clinical trials using Nylon PA12 and Selective Laser Sintering, a powder bed fusion printing technology. This technology will make accurate parts by sintering powder using a laser layer by layer.

Do you have a project? Don’t hesitate to contact our 3D printing experts or to directly upload your 3D file on our online 3D printing service!

Medical 3D printing is allowing to create a lot of different medical devices. It is now possible to 3D print devices such as surgical tools, orthotics, prosthetics, medical models to train surgeons, implants, dental crowns, all adapted to the specific needs of the patient.

Medical 3D printing regroups the variety of applications of 3D printing in the medical sector. This technology offers a lot of advantages such as customization, on-demand manufacturing, innovation or affordable costs. It is possible to 3D print prosthetics, orthotics, implants, dental crowns, surgical tools or surgical guides.

The main advantage of using 3D printing in the medical sector is customization. 3D printing offers the opportunity to print devices perfectly adapted to the patient’s needs, or tools adapted to the daily use of a surgeon. With additive manufacturing you can 3D print prosthetics or orthosis fitting perfectly the morphology of the patient.

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook