Medical 3D printing: How Additive Manufacturing can help treatment testing

Posted By Kat Plewa on Nov 23, 2018 | 0 comments

Additive Manufacturing has been used for medical purposes for a while. We already talked about 3D printed synthetic skin and organs. But there are plenty of other opportunities for 3D printing to not only improve our lives but even save them! In this blog, we look at how 3D technologies allow for safe, risk-free treatment testing. How is it possible? What is the future of medicine? Find out with our blog post.

How is 3D printing beneficial for the medical industry?

Thanks to 3D technologies, doctors around the world are able to help their patients, faster and more efficiently. A great example of using AM for medical applications are prosthetics, not only for humans but also animals. Moreover, whatever the use of 3D and medical technology, it is always patient specific and that’s the most important part.

Additive Manufacturing can not only improve the quality of life for patients but even save lives. Scientists are working on an artificial 3D printed heart. Can you imagine a world without a waiting list for organs? In the future, the doctors will simply 3D scan you and 3D print the exact replica of your organs.

This technology is already used for knee replacements, but this is not the only example of using Additive Manufacturing in the medical field. Let’s discover how medical 3D printing can revolutionize treatment testing.

Drug testing with medical 3D printing

Another way of saving lives with Additive Manufacturing is treatment testing. Each patient is different, there are never two identical cases. Which means that not every medicine will be received the same. Each person can react differently to drugs and that is a big issue in the medical field. How can we ethically test life-saving treatments? 3D printing provides an answer.

The possibility to cure Congenital Heart Disease

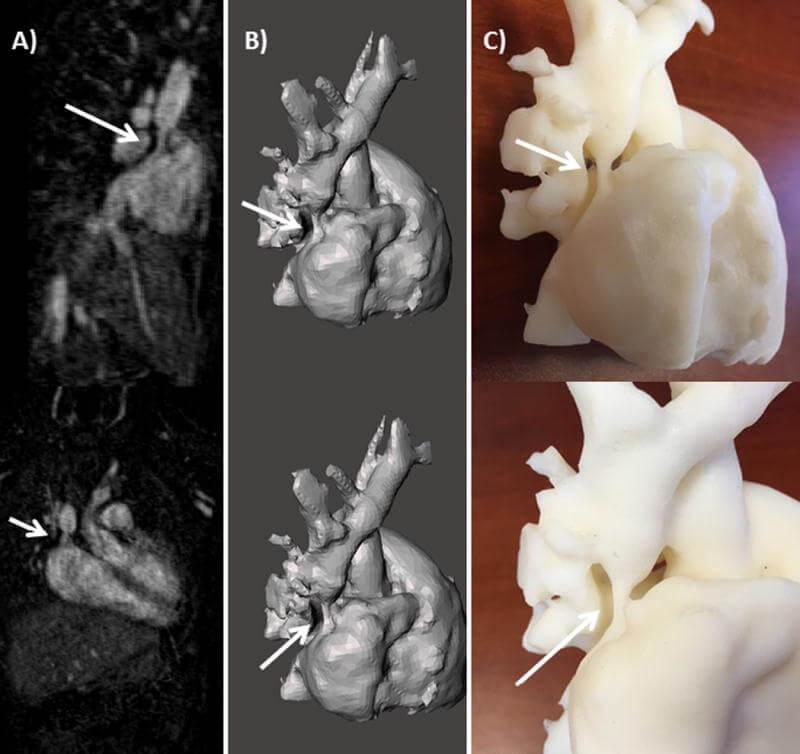

Congenital Heart Diseases are particularly hard as sometimes the surgery has to be performed on children, and their organs are very small, which makes it very difficult for doctors to operate. This was the case of a 4-year-old with a long segment stenosis of the SVC as it entered the anterior, right atrium to the right upper pulmonary venous baffle.

She’s still alive thanks to the use of 3D printing in medical applications. Her treatment was a surgery, a balloon angioplasty of the SVC to be exact. However, the doctors couldn’t get a clear vision of how they should proceed it. To solve that problem, data from MRI scans data were gathered to then be used for the design of a 3D model. This model was 3D printed giving the doctors clear view at the problem and confidence to execute the treatment.

Without medical 3D printing, the doctors would have no real idea of what they are dealing with and how risky the procedure really is. But a printed model gave them exactly what they needed. Thanks to Additive Manufacturing they could test different approaches and have a very strong plan for each step to save the child’s life.

Fighting super bacteria with Additive Manufacturing

Antibiotics brought ground-breaking change and improved our lives by miles. Unfortunately, they became too popular and are very often overused. This process leads to the bacteria becoming immune to the medicine. These multidrug-resistant bacteria are called ‘’superbugs’’. And ‘’super’’ means they also need very strong and complicated treatment, which requires highly equipped laboratories.

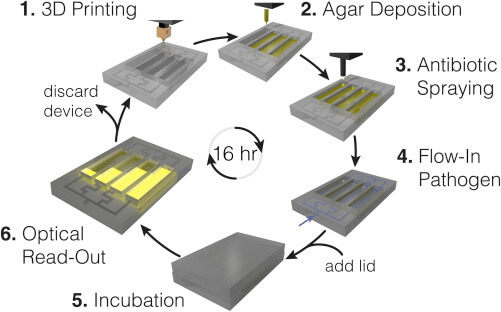

How can Additive Manufacturing help? Researchers developed an autonomous and inexpensive device that 3D prints diagnostic devices, then deposits gel and sprays the testing drug. This method is extremely convenient and can be used anywhere, in hospitals, homes or in a field. This is the future of medicine.

The process is fairly simple: first, a plastic device is 3D printed and keeps the testing environment sterile, it is then filled with growth medium, and lastly, the antibiotics are sprayed with an ink-jet technology onto the medium. But, that’s not where the mission of 3D printing finishes. When the sample for testing is applied through a fluid port, the 3D printer’s hot bed serves as an incubator making it possible to use in the field. And that’s all done in a very short amount of time when every minute counts.

3D printed, fully functional blood vessels

Other than testing drugs, we also need to determine if medical devices we put in a patient’s body are working. We can’t test them on other people, animal testing is ethically questionable, clinical trials and complicated FDA procedures limit the rate of progress in developing new, life-saving medical devices.

And here again, we see the use of medical 3D printing. It allows for a faster and safer way to test new mechanics without installing them in animals or other humans. Erica Cherry Kemmerling, an assistant professor of Mechanical Engineering at Tufts University and her team are currently working exactly on that issue.

With Additive Manufacturing, these university researchers are capable of 3D printing realistic models of human blood vessels and simulating a heart pumping blood! Sounds incredible? This use of medical 3D printing shows how much potential the technology has. Now doctors can 3D print fully functional organs and test how they act when different mechanical solutions are applied. Testing medical devices has never been easier, 3D printing is truly the future of medicine.

How can we use Medical 3D printing for testing breast cancer treatments?

An astonishing development in medical 3D printing was made by a student from the University of Waikato in New Zealand. Her name is Shalini Guleria and she took particular interest in breast cancer patients and bioprinting. How can we combine medical 3D printing and breast cancer treatments?

Guleria had an amazing idea. 3D bioprinting and the use of natural, human-safe materials are not new, so she used this technology to work with cancerous cells. First, the cells would be extracted from the patient, then implemented in hydrogel and 3D printed in a size of a fist to imitate a tumor. This printed model of a tumor then could be tested for different drugs, eliminating unnecessary, risky and sometimes unsuccessful drug testing on the patients.

The student explains “Currently the easiest way to do pharmaceutical tests on cancer cells is using 2D models, which is basically a petri dish where the cells stick to the bottom of the dish and you analyze them. But humans are three dimensional and 2D doesn’t really present an actual human tumor. Once the tumor is printed we will be able to slice it and look into the depths of the cell. You can look at how the tissues are growing, the fibers connecting and the cell organelles – the things that make the cell grow – how they differ to the 2D model.“

3D printing bones for effectively testing drugs for cancer

We already talked about 3D printed bones in a previous blog. Another take on using medical 3D printing involved scientists from Rice University who focused on bone cancer. Thanks to Additive Manufacturing they were able to mimic the biological environment to see how cells will react.

Researchers used medical 3D printing devices to produce scaffolds. It is a bone-like polymer which contains pores of different sizes to constrain fluids. The fluids flow and apply varying amounts of shear stress to the tumor cells. Those tests applied to a printed model show how are the bones reacting to the tumor and the tested drugs as well.

It is a revolutionary development which would be impossible to achieve without Additive Manufacturing technologies. Thanks to medical 3D printing, researchers are able to study a printed model of a tumor, but also the environment around it and how the treatment would influence the whole structure of the patient’s bones.

Can we find a cure for asthma with medical 3D printing?

Another example of using AM for medical applications is a company called Aspect Biosystems. They are working with two cutting-edge technologies: Additive Manufacturing and tissue engineering. One of their latest inventions is using medical 3D printing to simulate a human airway. This method allows doctors to preview an asthma attack by checking when the structures relax and when they stress.

Thanks to medical 3D printing scientists are capable of designing and printing the perfect tissue structure, acting as a live one. Moreover, 3D printed tissue also reacts as if it was alive. Without Additive Manufacturing it would be impossible to get such a precise architecture of the models, not to mention them being interactive and providing valuable data to the treatment testing. With printed models, they can easily test which drugs perform the best.

The magic of medical 3D printing

Actually, there is no magic. All the cases of using 3D printing for medical applications seem like science-fiction, but they are real, true examples of how unlimited the potential of medical 3D printing is. Additive Manufacturing gives researchers the possibility to develop new materials, which then can be safely used on humans to produce human body parts and to test life-saving treatments.

If this article was inspirational, let us know. You can start your journey with Additive Manufacturing with our online 3D printing service or if you need any help with your project, contact our Design Studio.

And don’t forget to stay up to date with 3D printing news with our Newsletter and Facebook!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook