3D printed bones: What is possible?

Posted By Lucie Gaget on Sep 26, 2018 | 0 comments

Are 3D printed bones a reality? Additive manufacturing can improve patients’ healthcare thanks to its various applications in the medical industry. 3D printing prostheses has become increasingly common, while 3D bioprinting is becoming an exciting solution for regenerative medicine. But is it possible to get real bones out of a 3D printer? If we can see these experiments in science-fiction movies, be prepared because it is now part of our reality.

Let’s see what’s possible thanks to the evolution of biomedical engineering and how, once again, a 3D printing application is helping to save lives.

3D printing bones for the medical industry

Bones and 3D

3D is a great asset when it comes to bone reconstruction. CT scans allow different things: you can convert these data to get 3D files and work on 3D software. 3D modeling software for the medical sector is essential. It allows for the creation of complex shapes, better visualization of the patient’s problem, or even simulating a surgery.

It can also be used to print the 3D file for surgery. But, in which cases would it be a good thing to 3D print bones? This process can be used for people suffering from either trauma or congenital defects, missing bones, skull reconstruction, bone defects, etc.

We saw in a recent blog post that it is already possible to 3D print knee replacement and jaw reconstruction. One of the reasons why additive manufacturing appears to be the best solution for bone reconstruction is mainly because it is a great manufacturing technique for making custom-made products. Nobody has the same bone structure, and 3D printing allows recreating any bone’s shape! Bone can be created according to the patient’s specific morphology.

Evolution of bioprinting

Bioprinting is exciting; now, it is becoming possible and could significantly impact the medical industry! Biomedical engineering indeed has a bright future. Bioprinting is working using the cells of the patients. It will recreate a body part using the patient’s cells to create a tissue matching the patient.

It is possible, for the moment, to print living tissue to make skin tissues or some organ parts, but it could be the perfect solution in the future to recreate precisely the patient’s natural bone. Bone tissue engineering is about revolutionizing bone surgery!

3D printed bones: Promising experiments have been made!

Let’s see through these first experiments how this technique is proper and what kind of problems it will solve. One thing is sure already: this cutting-edge technology will improve the daily life of many patients and could even save lives!

The 3D printed shinbone transplant

A 27-year-old man from Queensland almost lost his leg after an infection that rotted most of the bone in his leg. The bone had to be removed and the magic of 3D printing started. This Australian man almost lost his leg because of this infection but making a new leg using the 3D technology to facilitate a new bone formation was possible.

This 3D-printed bone has been made using what was left of his bone and some of his nerves to create a 36 centimeters scaffold. This 3D-printed bone is a prop and will allow the bone to regrow. Hopefully, this man will be able to walk again thanks to the use of the 3D technology.

It is proof that this manufacturing technique will be a precious help for bone reconstruction.

all3Dp.com

3D printing hyperelastic bones

Scientists from Northwestern University developed a new 3D printing process to print hyperelastic bones. What is the point of creating hyperelastic bones? This new technology allows bone regrowth with the growth of the body, which could be incredibly helpful for transplants on children, for example! This way, the behavior of synthetic bone is similar to the conduct of natural bone.

A printing material made of bone, graphene, ceramic, and metal is available from the bioprinter manufacturer Allevi and Dimension Inx, the scientist’s team that developed this impressive bone.

The development of new 3D printing materials leads to new experimentations like this one, which was impossible a few years earlier. This hyperelastic bone can help repair damaged bone by printing an implant of the same size and allowing bone regeneration.

Watch the video below to see how this bioprinter works and how elastic this bio-printed material is:

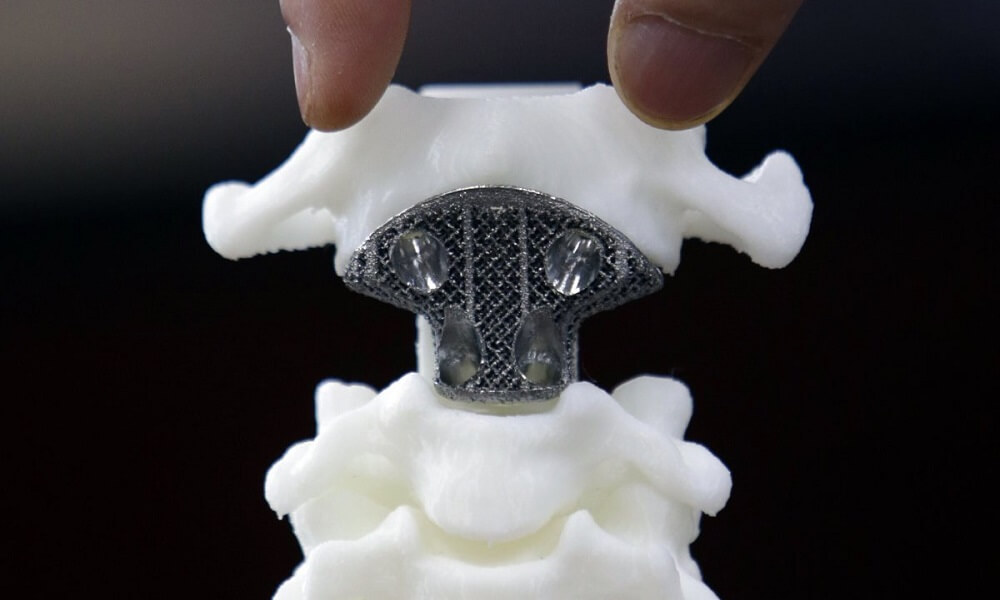

The 3D-printed vertebra

A 12-year-old boy had a vertebra removed due to prevent cancer from spreading. Indeed, the boy has a malignant tumor on the spinal cord. His vertebral implant was created using a 3D printer and made out of titanium powder. It was the first surgery of this kind, but not the last one!

Indeed, recently, in India, a woman had her spine 3D printed with titanium: this surgery saved her from paralysis and death. A disease manifested in her spine and caused extensive damage. As a result, she no longer had support between her skull and her lower spine. The compression of her respiratory nerves could even have caused her death.

“The patient today, on 12 postoperative days, is now walking with minimal support, all her pain has gone, her voice and dysphasia have recovered completely, and, most importantly, her life was saved by this technique,” affirms Dr. Naik, her surgeon.

Improving the quality of 3D printed bones for orthopedic surgeries

Researchers worked on the improvement of mechanical properties of 3D printed bones. Bone tissue engineering appears to be an excellent solution for many sectors, but the strength of those implants had to be improved to avoid fractures.

The solution is to add a particular treatment. With the addition of Calcitonin Receptor Fragment Peptide (CRFP), the implant showed a significant increase in the compressive modulus. This experiment improved the mechanical strength of the 3D scaffolds.

This is proof that researchers are interested in 3D technology and believe in it!

The 3D-printed skull

If additive manufacturing can help save human lives, it is also possible to save animal lives. 3D printed prosthetics for animals are already helping cats, dogs, turtles, penguins, and lizards live better lives. But what about 3D-printed bones?

Metal 3D printing has been used to 3D print a titanium skull for a dog with cancer. Doctors used these data from CT scans to simulate the surgery with 3D modeling software. The aim was to map the dimension of the 3D-printed skull cap.

Image: Michelle Oblak

70% of the dog’s skull had to be removed and replaced with a custom-made skull cap! The surgery has been a real success, and the little dog is now cancer-free, thanks to this 3D-printed skull reconstruction.

As you can see, this technology is revolutionizing the medical sector, as scientists and researchers are showing a growing interest in tissue engineering using 3D printing. The treatment possibilities will be endless thanks to this 3D technology. It allows complex building shapes to make a patient-specific implant in no time.

The evolution of bioprinting is also bringing new solutions to cure some diseases, even when it comes to bones. Printing organs, bones, and skin is now possible using patients’ cells. How far will this 3D printing technology go? Only the future can tell us, but 3D-printed ones could easily replace real bones in the future to repair bone defects or replace missing bones.

If you have a medical 3D printing idea, you can upload your 3D files to our online 3D printing service. You will get your 3D printed parts in a few days!

Do you need more information about medical 3D printing? Don’t forget to subscribe to our newsletter and check out our Learning Hub!

Photo credit: https://www.businessinsider.com.au

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook