VeroClear 3D printing material

3D print your project with our translucent resin! Our VeroClear will offer you great properties. Get all information, tricks, know-how, and advice to help you print your 3D model in our VeroClear resin material.

VeroClear Material Guide

What is VeroClear material?

Our VeroClear resin material (translucent Polyjet resin) creates 3D printed objects from a base of photosensitive polymer liquid. That translucent liquid is then solidified by UV light layer by layer to create rigid and highly detailed prints that are comparable to injection molded plastics. 3D printing in VeroClear gives you access to great properties not available with our other 3D printing materials. While VeroClear is originally translucent, it is possible to make it more transparent with our polishing finishings or by polishing your part by yourself. The final product has a naturally smooth surface which can be polished further to create near full transparency!

If you want more information about this VeroClear material, and find out all technical specifications such as wall thickness, temperature resistance, tensile modulus, you will find them in the design guidelines section. Be sure to respect all design guidelines for 3D printing using PolyJet technology, in order to make the most of the benefits of additive manufacturing and get the best part possible for your project.

What can you do with VeroClear material?

VeroClear Resin 3D prints are particularly smooth and precise. This 3D printing technology is perfect for ornamental objects, but they can also be used for more mechanical uses if the strain on the object is not too great.

The VeroClear Resin (translucent Polyjet resin) is often used for prototyping, but its smooth surface and its accuracy make it also quite suitable for end-products such as consumer products for example.

VeroClear resin simulates almost perfectly PMMA (polymethil methacylate), which is commonly known as acrylic or Plexiglas. The strength, stiffness, elongation at break and impact resistance all fall within the range of average values for PMMA. VeroClear resin can be used as an alternative to glass for lenses, clear covers, dispensers, and light pipes.

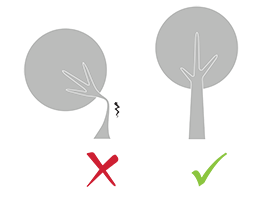

Our VeroClear material can be used for large volumes with really small details thanks to the great accuracy of the PolyJet 3D printing process. It is not recommended to 3D print wired shapes using this resin material.

With respect to water qualities, VeroClear Resin is water-resistant but not waterproof. Thus the 3D object must not rest in contact with water for extended periods of time. When it comes to temperature resistance, if the 3D printed part is subjected to heat above 70°C (160°F), it is possible that the physical form of the object can be significantly altered.. Be careful, the heat resistance of VeroClear is lower than for PMMA.

Pricing

The printing price of your design is calculated automatically the moment it is uploaded. As you modify your object (changing material, finishing, size, using batch control or hollowing feature, etc.) you will note that the price changes automatically. The pricing is based on a series of factors, including total volume, object size, and bounding box – to name a few.

Keep in mind that adding finishing will extend the processing time. The estimated shipping time is also calculated automatically as the object is uploaded and each time you make a modification on it. Delivery time should be added to processing time.

For more information, check our pricing page.

What is the 3D printing process for VeroClear?

VeroClear Resin 3D prints are created through a process of photosensitive liquid polymerization, using Polyjet technology. A UV light passes over where the object will be, hardening the liquid with a high level of accuracy. Another printer head simultaneously injects fine layers of FullCore 705 (another, more fragile, plastic material) which are used as supports during the printing process and are removed after the print is completed. The process of fine layer polymerization is repeated until the object is finished.

What are the finishing options available for our VeroCear?

The available finishing for our VeroClear resin:

- Translucide: clear and colorless

- Transparent: through translucide resin polishing (available only on quotation)

| Standard layer thickness | 28µm |

Our Objet 30 Pro by Stratasys allows us to 3D print with a layer thickness of 28 µm or 0.028 mm. In consequence, it is important that your 3D designs are exported with the highest quality possible. This will avoid any sort of triangulation during the print – though keep in mind your file cannot be greater than 50mb.

| Maximum size | 203 x 254 x 251 mm |

The maximum dimensions of your models are limited by the physical size of our 3D printers – nothing can be printed larger than the printer bed.

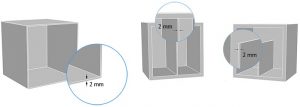

| Minimum wall thickness | 2mm |

The walls of your object must be thick enough to support the weight of the 3D printed object without breaking under its own weight. We recommend designing your model with the material’s minimum design standards. A minimum wall thickness of 2 mm is recommended for VeroClear Resin (Translucent PolyJet resin).

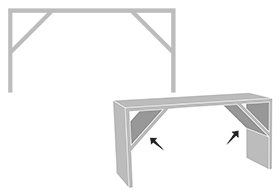

Add a support structure to maintain stability. For example, if you are modeling a bust of a person, you can attach thin aspects of the design like the ears in more places around the model’s head. Doing that will avoid cantilevered and easily breakable elements in the final print.

Sculpteo offers an online solidity check tool which highlights parts of the print that may be too thin for a print. From there you are able to tweak your design in order to create an object that is an appropriate thickness. To use it, you just need to upload your 3D file, select your material and click on “Verification” tab.

Do not forget

Keep in mind that our solidity check tool does not detect physical aberrations such as floating parts, unstable position, parts supporting too much weight relative to their thickness, etc. Particular care must be given to the geometry of your design and the most stressed parts must be thickened.

| Minimum size of details | 0.2mm |

| Minimum height and width details | Embossed: 0.5 mm Engraved : 0.5 mm |

| Minimum height and width for a readable text | 0.8mm |

| Enlargement ratio | 1/1 |

A detail’s minimum precision is mainly determined by the resolution of our printers. However, during the cleaning process, a fine layer of detail can also be lost. In order for a detail and text to be visible, we recommend following our recommended sizes at the very least. To ensure details will be visible, their width should be at least as big as their depth.

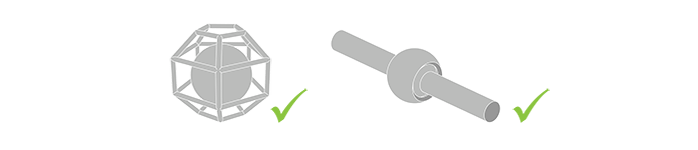

| Enclosed parts ? | Yes |

| Interlocking parts ? | Yes |

Our VeroClear resin material (translucent Polyjet resin) has the ability to print some of the most complex designs of our 3D printing materials. An example of a complex design is a volume enclosed within another volume or with articulations. Our resin 3D printers have the ability to print in a fully interlocked object out of the printer.

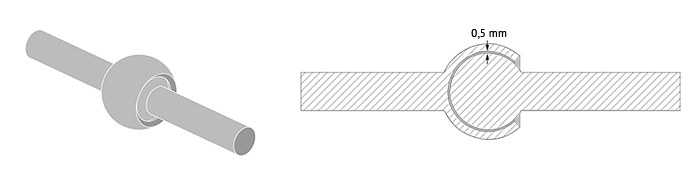

| Minimum spacing between fixed walls | 0.4 mm |

| Minimum clearance between parts | 0.4 mm |

For a successful 3D print a minimum clearance between objects is required to allow removing support material after the process of photopolymerization. If this space is not left within the design, the 3D printed object will be a solid. This is particularly important for articulated objects – as the space left between the walls will define the object’s ability to move.

Reaching deep areas is more difficult while removing support material. For this reason, the deeper the object is the bigger empty space should be.

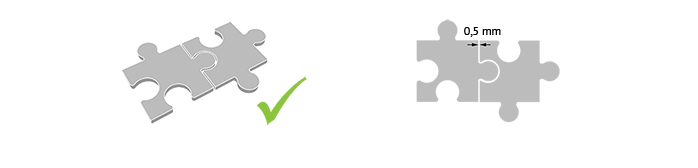

| Assembly? | Yes |

| Minimum space | 0.4 mm |

Objects printed in VeroClear resin can be printed to be assembled. As long as a width of at least 0.4 mm is left between the different parts of the object.

| Hollowing ? | Non |

Because of its printing technique, our VeroClear resin 3D printing process does not allow for the hollowing of your object. For this reason, the option is not available during checkout.

For the same reason, it is not possible to create an empty cavity within a closed resin object. If the object were hollowed, the 3D resin printer would add support elements in the empty space. Those elements run a high risk of breaking as the object is handled.

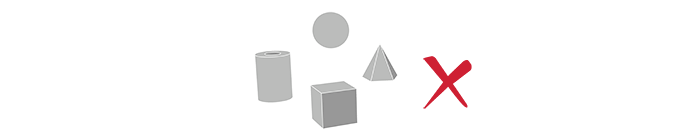

| Files with Multiple Objects ? | No |

It is not possible to upload a file to be printed in VeroClear resin (translucent Polyjet resin) with multiple objects.

Ready to 3D print with VeroClear?

With Sculpteo’s online 3D printing service you’re just a few clicks away from professional VeroClear resin 3D printing. Your 3D model is printed with the highest quality and delivered straight to your door.

Get started now!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook