Transparent 3D Printing: what are your options? (2021 Update)

Posted By Kat Plewa on Nov 27, 2019 | 0 comments

Transparency is sought after for many applications and in a wide range of industries: from the production of lenses for optical engineering or medical purposes to the manufacturing of aesthetically pleasing casings for products.

With the recent leaps, additive manufacturing technology has made, 3D printing is increasingly being used to produce transparent objects. In this blog post, we will cover all you need to know about transparent 3D printing, the material and fabrication options available and how to overcome the challenges associated with this 3D printing technique in order for you to get the most transparent results possible.

What exactly is transparent 3D printing?

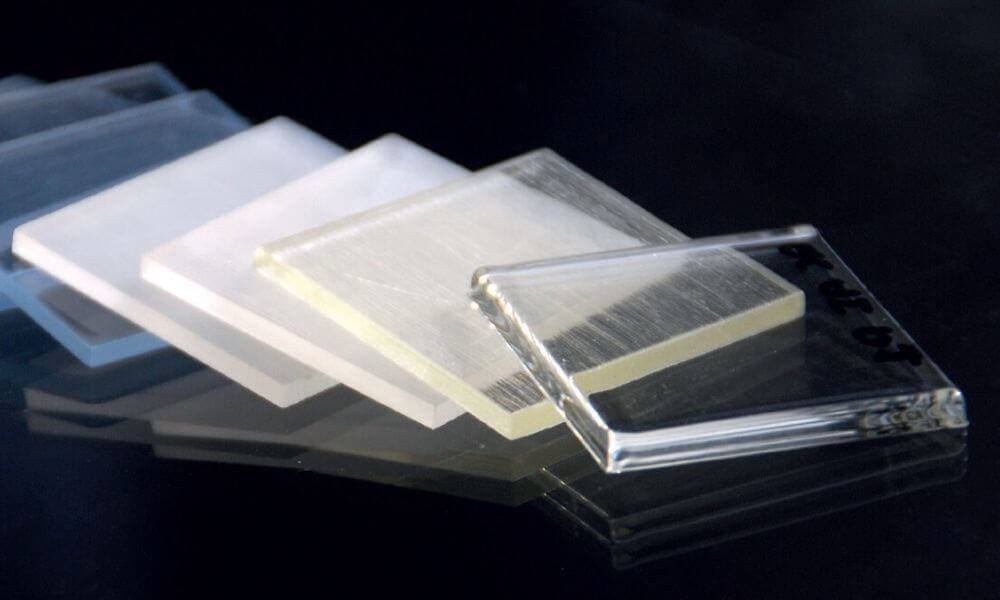

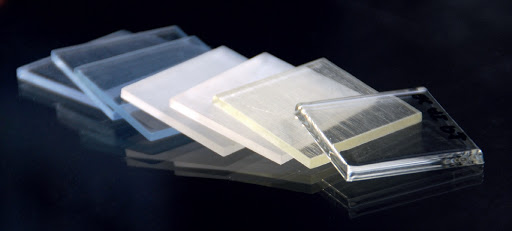

Transparent 3D printing refers to 3D printed objects of varying degrees of translucency. The results obtained range from translucent to relatively transparent. This diversity in results can be attributed to multiple factors including the nature of the 3D model, the type of 3D printer used, 3D printing settings, the choice of material, and the post production treatment.

It is important to understand that achieving fully transparent prints can be challenging depending on the additive manufacturing technology and printing materials selected.

Now let’s take a look at what you can do to maximize the transparency of your 3D print from the first step; when you 3D model your piece or part.

3D modeling for maximum transparency

When it comes to the 3D model you wish to 3D print, it is important to remember that more complex geometries tend to refract light more and are less likely to turn out very clear. This is particularly true for curved designs since curves redirect light.

That being said, to minimize light refraction, it is recommended that you 3D model your object with the thinnest walls possible. This is because thicker walls will disperse more light and lead to a more opaque appearance once the object is 3D printed. However, keep in mind the design guidelines and minimum wall thickness required by the technology.

Which 3D printing technology is the best for your project?

Pick the right 3D method depending on the nature of your project. Are you working on a prototype? Or do you need a fully functional final product? Considering the purpose of your 3D printed object, you should choose the desired technology. Each of the presented technologies will benefit your production in a different way. Let’s take a closer look!

FDM

FDM 3D printing technology is one of the most well known in the industry. It produces your 3D models using a filament. The filament is heated up in the nozzle and squirted through in the shape of your object, layer by layer.

Due to the nature of the FDM printing process, very small gaps can form between the layers which in turn contributes to less light passing through the surface of the 3D printed object. Layer lines which also tend to be more visible with the use of FDM 3D printers also disperse light. It is this light refraction that interferes with transparency and minimizing it through the design and production process can significantly improve the outcome.

Furthermore, finding the optimal settings for transparent printing using an FDM 3D printer is a challenging process as you depend on trial and error to figure out both the best parameters for your machine and chosen material. Among the settings, you have to adjust for are material extrusion temperature and flow rate, print bed temperature, printing speed, layer height thickness, and nozzle diameter.

SLA

SLA or Stereolithography uses photochemical processes to produce your parts with polymer resins. A strong advantage of this 3D printing process is very thin layers, which therefore produces very good results for transparent 3D printing.

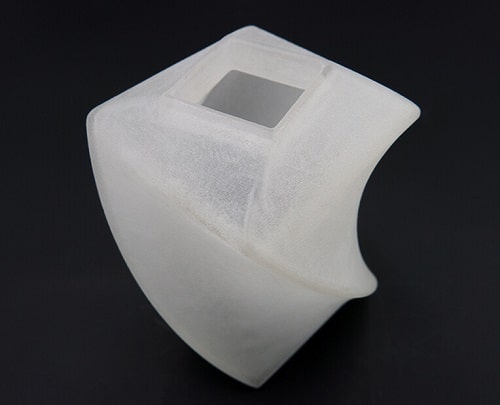

SLA has very satisfactory results when it comes to optical transparency. This 3D printing method is best for visual applications where a smooth surface finish and high levels of detail are sought after. It is important to note, however, that SLA 3D prints have support structures that require removing in the post-production phase and this can affect the final appearance of your object.

Polyjet Technology

Polyjet 3D printing is among the most advanced additive manufacturing technologies. It works by jetting resin onto the build platform. The resin is immediately UV cured in the shape of your 3D model, layer by layer.

It results in very smooth surfaces and is, therefore, the method to adopt if you wish to obtain high dimensional accuracy. It is well suited for both tooling, visual prototypes, and finished products. It is the technology best suited for detailed 3D prints.

The results closely resemble injection molding but with all the advantages an additive manufacturing process that doesn’t require a mold has to offer. You can learn more about how the two manufacturing methods compare in our injection molding vs 3D printing blog post.

Transparent materials for 3D printing

Once you decided on the 3D technology, the next step is to pick the right material. The materials are different for various technologies. Your decision should depend on the purpose of your 3D object and how it’s going to be used. A prototype maybe doesn’t need to be 100% transparent but has to withstand a lot of tests. However, a decorative element doesn’t need to present as much strength but has to be aesthetically pleasing.

Transparent Filaments for FDM 3D printing

Although Fused Deposition Modeling (FDM) provides the widest range of materials to choose from thanks to the diversity of transparent filament types available, it does not produce the smoothest surfaces which in turn disperses light and reduces transparency.

Clear 3D printing filaments are made from a diversity of plastics including the following:

Polylactic acid (PLA) filaments represent the most commonly used FDM 3D printing material. Their transparency depends highly on its quality. However, PLA filaments usually have a slight yellowish tinge to them as they are made from natural raw material which also makes them biodegradable.

Acrylonitrile butadiene styrene (ABS) is translucent rather than transparent. This is because it is blended with an additive to make it clear which it isn’t naturally. It requires post-printing finishing for more transparent results.

PMMA prints rather clearly when compared to other materials and is available in a range of colors.

Polycarbonate (PC) is a clear yet durable 3D printing filament with a glossy sheen to it.

Polyethylene terephthalate glycol (PETG) is possibly the clearest 3D printing filament available.

Transparent Resin for SLA

SLA 3D printing requires the use of resin. There are many brands of transparent resin available. Clear resins are not always completely transparent before post-production but manage to deliver optically viable pieces. Objects fabricated in the resin may have a bluish tinge that is more prominent in pieces that have a thickness of 2 centimeters or more. This depends on the resin used and SLA transparent resin can also be colored with the addition of pigment.

Clear Resin

Polyjet technology also relies on the resin to 3D print pieces. This photosensitive polymer liquid represents a translucent liquid that solidifies using UV light and results in particularly accurate and smooth surfaces. It has good impact resistance and it’s strong making it ideal for both prototypes and end-products. Polyjet resin can be polished to give it the most transparent finish.

At Sculpteo, we offer VeroClear Resin which is ideal for both prototyping purposes and end-products. Its applications range from offering a more resistant alternative to glass lenses and light pipes, to creating clear covers. VeroClear also boasts water-resistant and heat-resistant (up to 45 – 50°C) properties. The finishes we offer at Sculpteo to make sure your product is as transparent as it can be are Translucide and Transparent. Find out more about the specifics of VeroClear Resin and how it can benefit your projects on the dedicated material page.

Post-production

There are many post-production treatments to improve the transparency of 3D prints fabricated using more or less clear materials. These include sanding, resin dipping, and spray and epoxy coating as well as vapor smoothing using acetone and polishing (for polyjet prints).

When sanding a 3D printed piece, it is recommended to increase the grit of the sandpaper used incrementally. Polyjet, SLA and FDM 3D prints can all be sanded. Although labor-intensive, this method can lead to optically transparent results.

Spray and epoxy coating is also suitable for both SLA and FDM 3D prints. It is a very popular treatment but multiple applications are usually required.

Resin dipping is a post-treatment method only used for SLA 3D prints. It consists of submerging 3D printed objects in resin before removing them so they can dry. It is only suitable for flat objects such as lenses. The results are clear and very smooth.

Are you ready to start your next transparent 3D printing project?

As detailed in this guide to transparent 3D printing, there are multiple possibilities available to produce pieces of varying degrees of transparency. With the right choice of material, optimal print settings and 3D model, as well as the best technology for your needs and some post-processing you too can have your optically transparent object fabricated.

Are you looking to produce a transparent part? Make sure to explore Sculpteo’s online 3D printing service; it’s as simple as uploading your STL files and selecting our VeroClear material. You can also contact us in case of any questions.

Subscribe to our Newsletter and follow us on Facebook to get the latest 3D printing news!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook