| Minimum wall thickness (flexible) | 0.8mm

|

| Minimum wall thickness(rigid) | 2mm

|

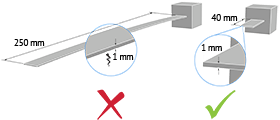

| Minimum wall thickness stemmed elements | 0.8mm with support

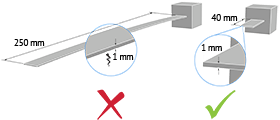

1mm without support

|

| Minimum wall thickness particular design aspects | 1-2mm |

Disclaimer: While parts with a minimum wall thickness of 0.8 mm are printable, we kindly remind you that a minimum wall thickness of 3 mm is required in order to be compliant with the materials Blue Card and UL-94 V-0 certifications.

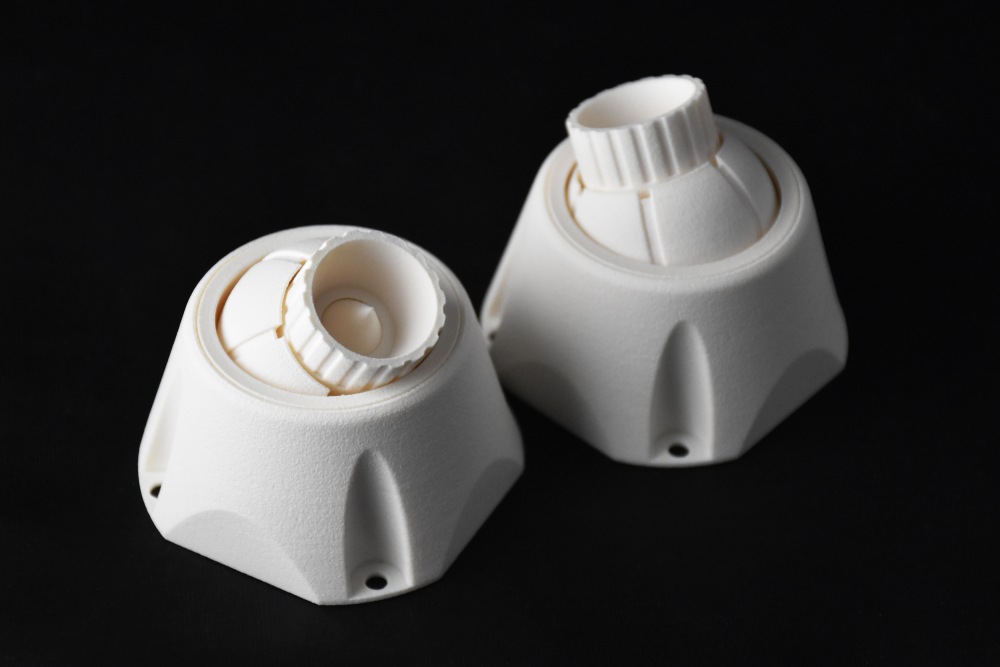

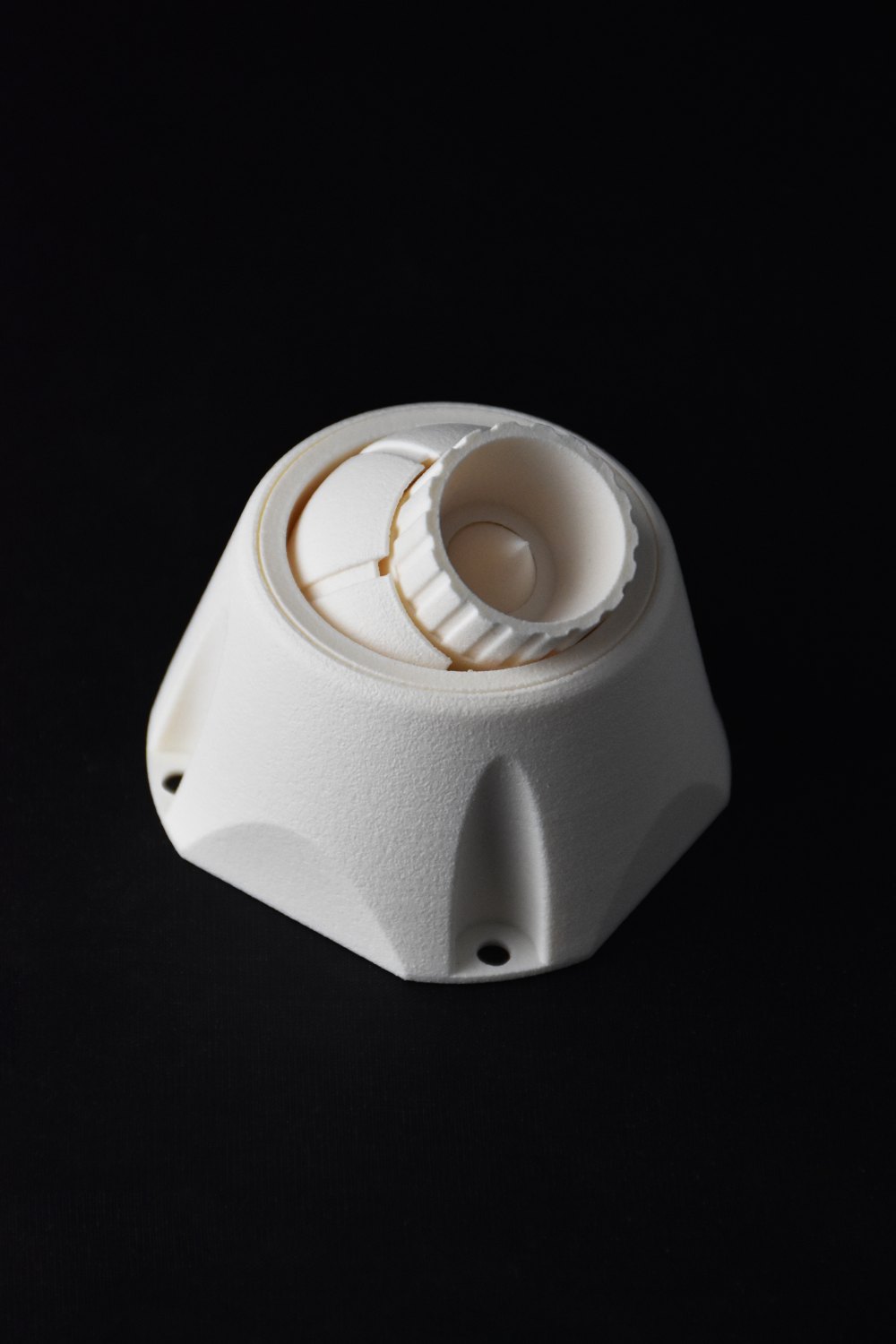

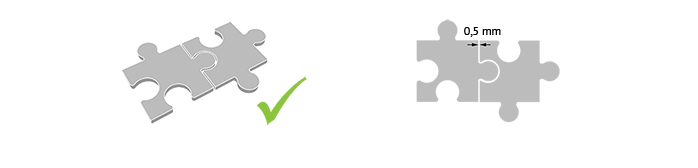

The walls of your design must adhere to a minimum thickness of 0.8 mm in order to guarantee the structure will not break. If the walls of your model are less than 0.8 mm, you can add a support structure to maintain stability.

A stemmed element is a design aspect which is at least twice as long as it is thick. For unsupported and stemmed elements or parts of the design with a particular design constraint, it is also important to respect a minimum thickness of 1 mm in order to guarantee the object will not break.

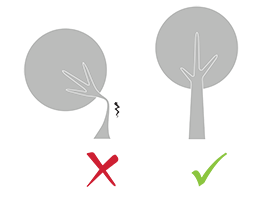

Tip

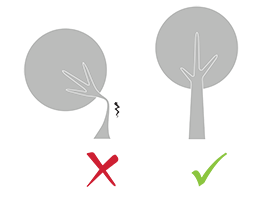

Add a support structure to maintain stability. For example, if you are modelling a bust of a person, you can attach thin aspects of the design like the ears in more places around the model’s head. Doing that will avoid cantilevered and easily breakable elements in the final print.

With a 0.8 wall thickness, your design will be slightly flexible. To obtain more rigidity, we advise a 2mm wall thickness.

Good to know

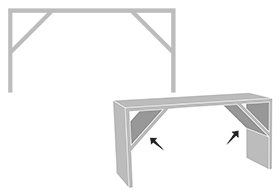

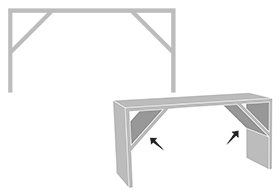

Thin walls supporting large, heavy models can warp under the weight of itself.

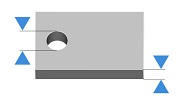

Sculpteo offers an online solidity check tool which highlights parts of the print that may be too thin for a print. From there you are able to tweak your design in order to create an object that is an appropriate thickness. To use it, you just need to upload your 3D file, select your material and click on “Verification” tab.

It is also important to keep in mind that the object is to be printed into real life. Thus if a thin aspect is supporting something that is too heavy for it, it may break – even though it is possible within the physics provided by your 3D modeling software. We recommend adding a bit of thickness to the places that will get a lot of handling, or that support the most weight.

Keep in mind that our solidity check tool does not detect physical aberrations such as floating parts, unstable position, parts supporting too much weight relative to their thickness, etc. Particular care must be given to the geometry of your design and the most stressed parts must be thickened.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook