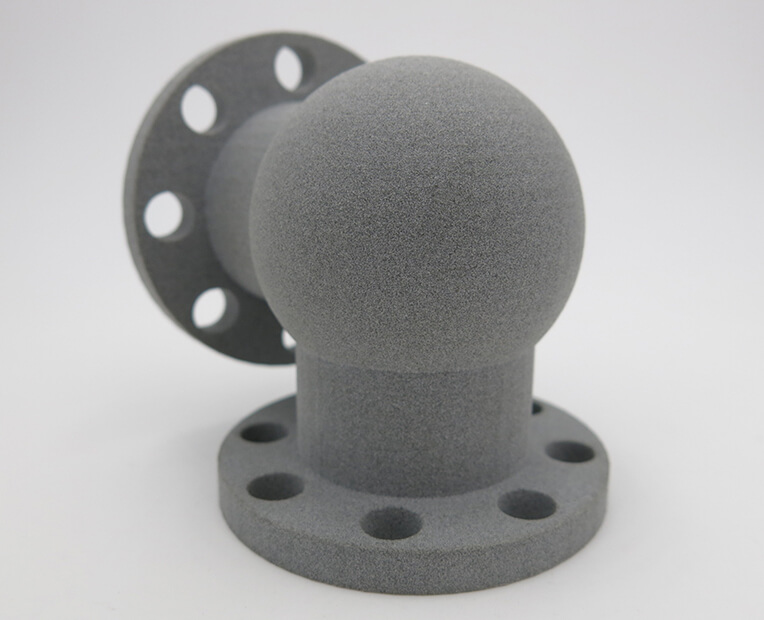

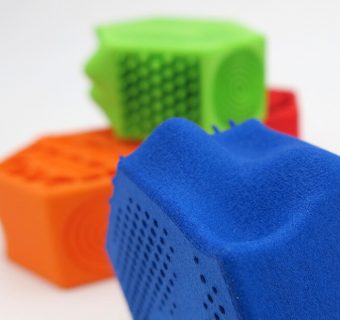

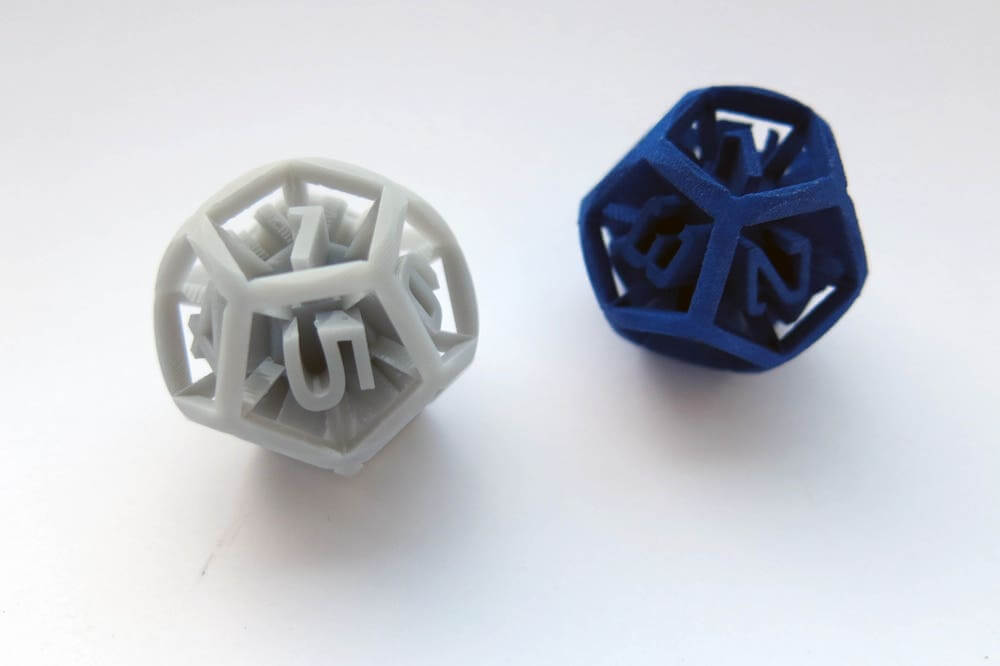

Selective Laser Sintering Technology

Order your parts 3D printed with SLS for rapid prototyping and end-use production. Discover the Selective Laser Sintering (SLS) 3D printing technology and how you can use it to produce your objects from 1 - 10k parts.

- ISO 9001

- Fast Turnaround

- Secure File Upload

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook