Customer Stories

- Innovation

- Adaptability

- Scalability

Unleashing the power of modularity : How REF Bikes is creating the modular bike of tomorrow

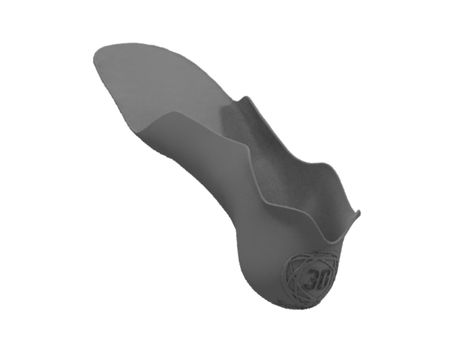

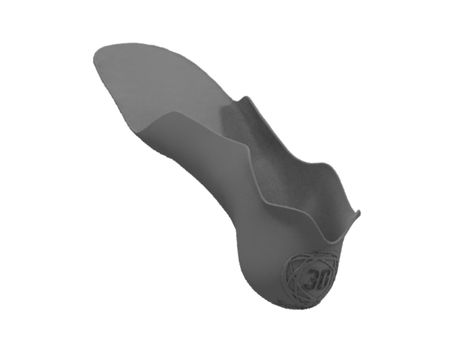

Schlather uses 3D printing to create customized medical aids

The integration of 3D construction has opened up completely new possibilities for the production of orthopedic aids for Schlather GmbH. With 3D printing and PP material, Schlather developed a Dynamic Foot Orthosis (DFO) to correct various deformities such as a clubfoot or extremely high arches.

They Trust Us

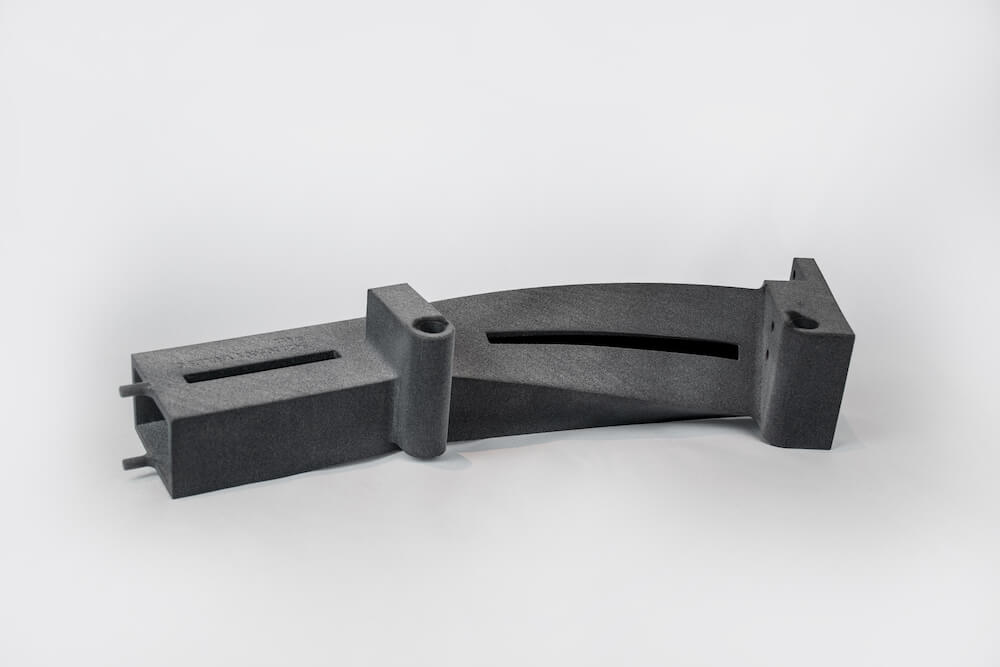

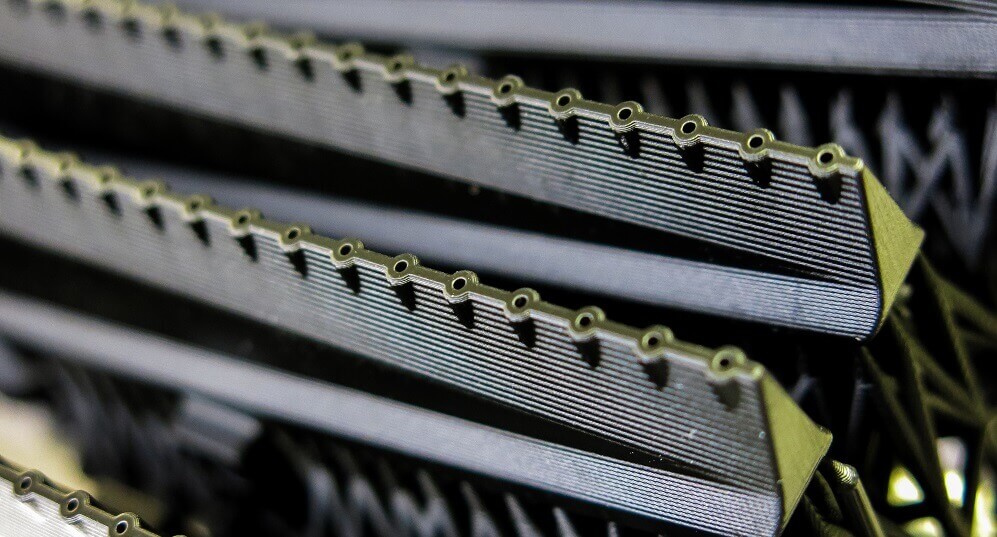

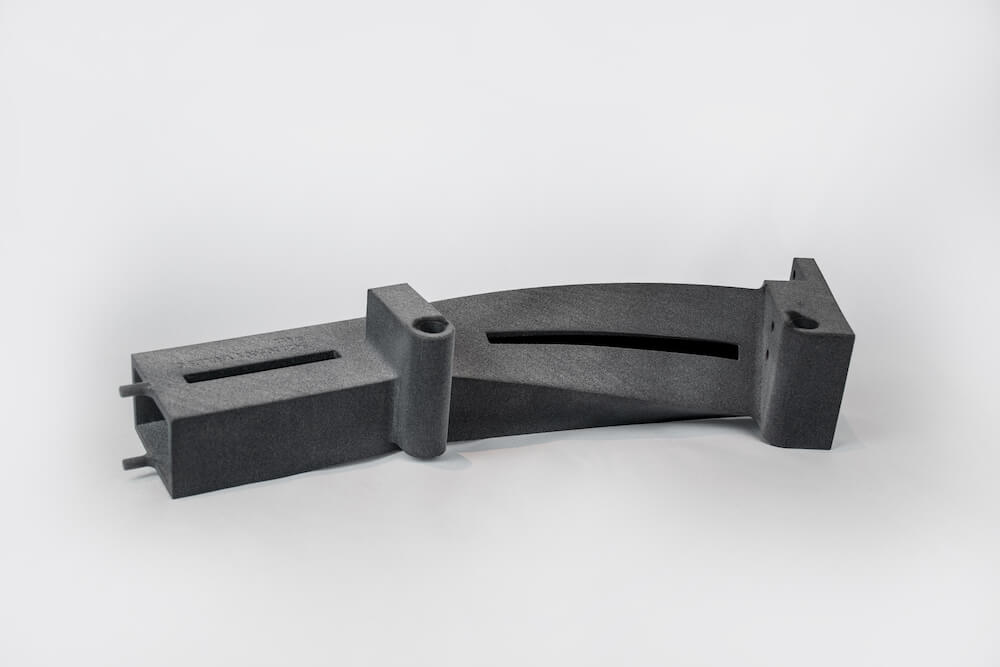

REF BIKES: Creating a modulable & adaptable bike

REF Bikes is changing the cycle industry with their modular bike system, allowing cyclists to modify their bikes and embark on all kinds of adventures!

ARTHA: Helping the visually impaired better perceive their environment

French start-up Artha is changing the way visually impaired people can perceive their environment, thanks to an innovative lumbar belt sensitive concept.

Macu4: Additive Manufacturing helps with designing, iteration and the production of a successful arm prosthesis, The Explorer!

Macu4 turns to the innovative potential of AM to create arm prostheses that are affordable, lightweight, and versatile.

Unlocking the Mysteries of the Brain with an Adaptable Headset

A French research institute was looking for a way to optimize their process to create the best headset possible for their research – which implies finding the adapted prototyping technique, as well as the best material for this usage. Particular attention was also paid to the design of these headsets, with a specific lattice model created with Ultrasim® 3D Lattice Engine from Forward AM.

Daniel Robert Orthopedics uses 3D printing to create unique eco-responsible orthopedic devices.

Daniel Robert Orthopedics explored 3D printing to offer a unique and custom device that allows for comfort, breathability and is lightweight, while still maintaining flexibility in manufacturing and design.

Schlather uses 3D printing to create customized medical aids

The integration of 3D construction has opened up completely new possibilities for the production of orthopedic aids for Schlather GmbH. With 3D printing and PP material, Schlather developed a Dynamic Foot Orthosis (DFO) to correct various deformities such as a clubfoot or extremely high arches.

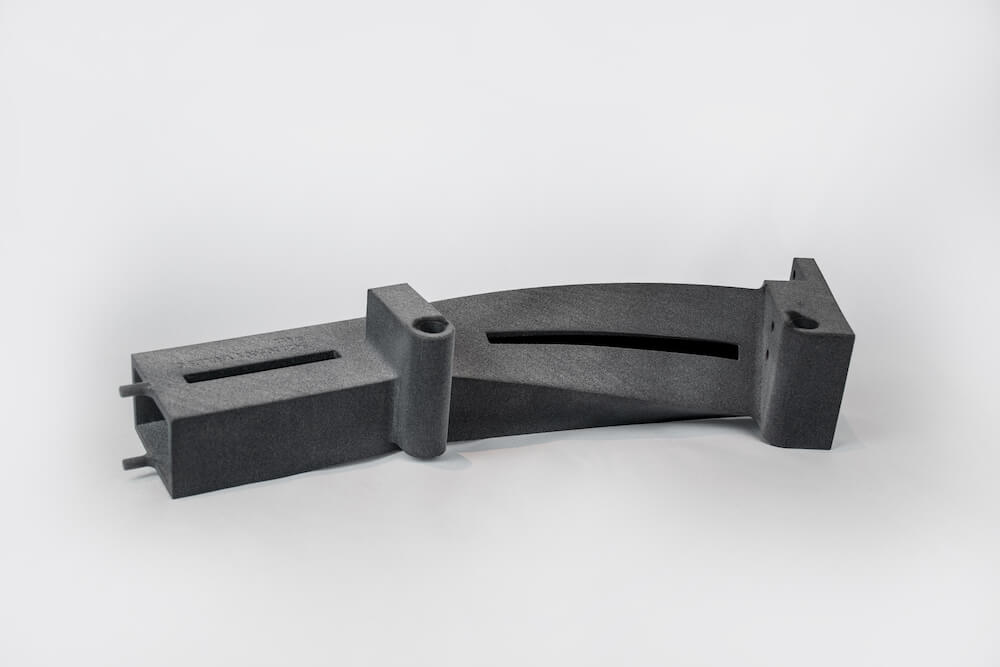

GIRBAU: Freedom of design to improve their machines performances

Girbau turned to 3D printing for the speed, efficiency, limitless design possibilities, and cost-effectiveness of this technology to create the single solution part they needed to optimize their folding machines.

Lunaar is using 3D Printing to customize Augmented Reality headsets!

Augmented collaboration experts Lunaar have developed an adaptable clip solution to fit Personal Protective Equipment helmets and bring Augmented Reality to workers, enabling various industries around the world to enter the digital age.

KOOVEA: Developing reliable sensors

Koovea explored 3D printing to enter the market with high-quality products and technologies. Koovea developed their temperature sensors through an intense iteration process to create a reliable solution for their products.

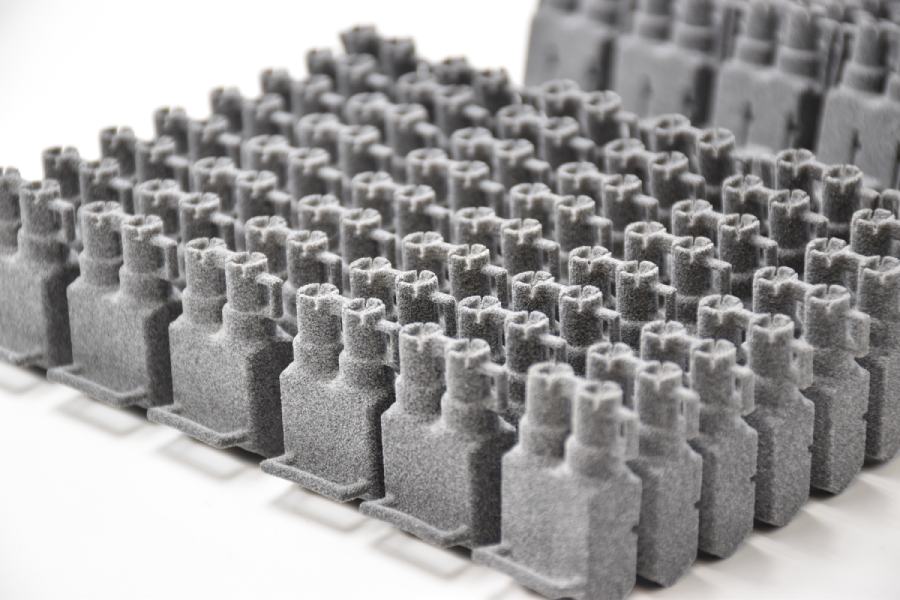

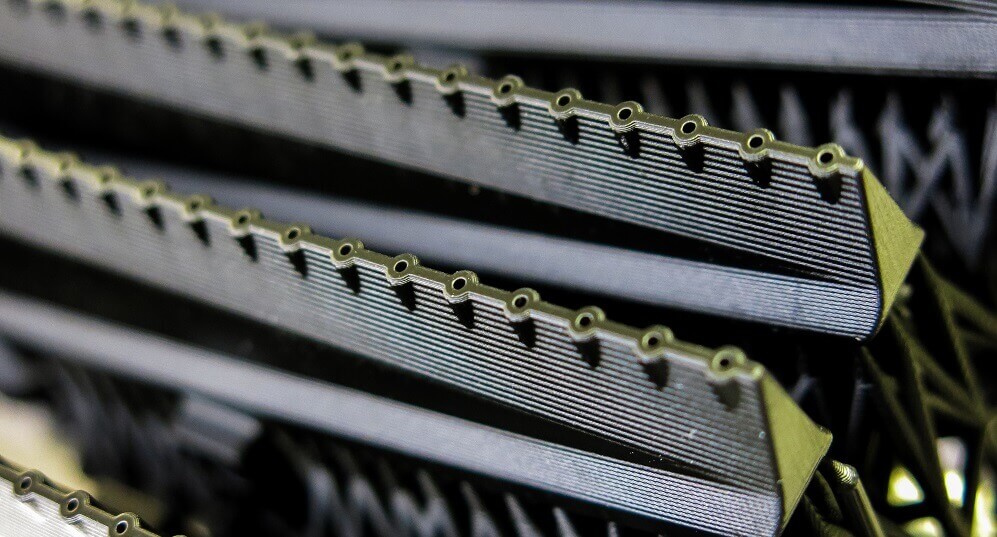

BERNAY AUTOMATION: Streamlines its production process quickly and efficiently using AM

To mass-customize their vibrating bowls in a quick and cost-effective way, Bernay Automation turned to the innovative power of 3D printing and Sculpteo’s reliable online manufacturing services. By adopting additive manufacturing technology into its production process the company was also able to streamline and create a sustainable production process while still maintaining a competitive edge.

UWTI: From small series to production in a short time

Producing this game was a new challenge for Arnaud and Arnaud, going from prototyping to small series production in a short time. With 3D printing, Arnaud and Arnaud were able to adapt production to market demand, to reduce inventory and production overruns.

OVERLINE SYSTEM: Adaptable headphones to meet customers needs

Overline Systems turned to 3D printing technology to create a frame for their headphones that could easily be changed to address market trends and customer needs. They also needed a fast turnaround time to get their headphones into the market, with economic iterations to final parts.

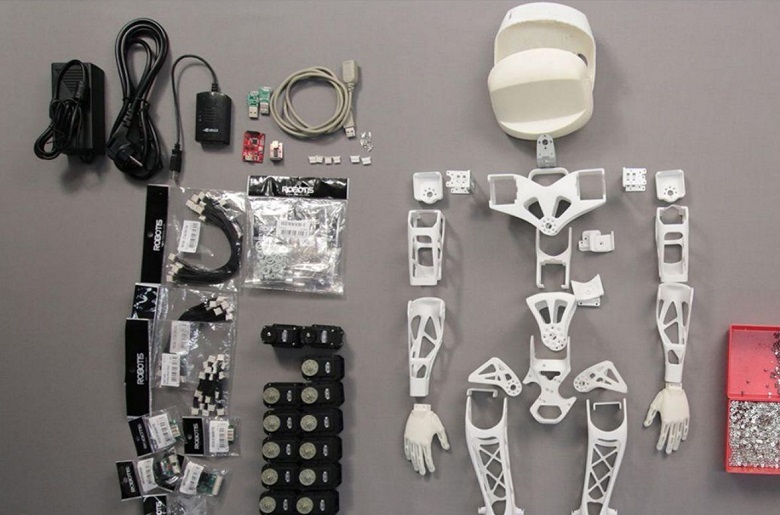

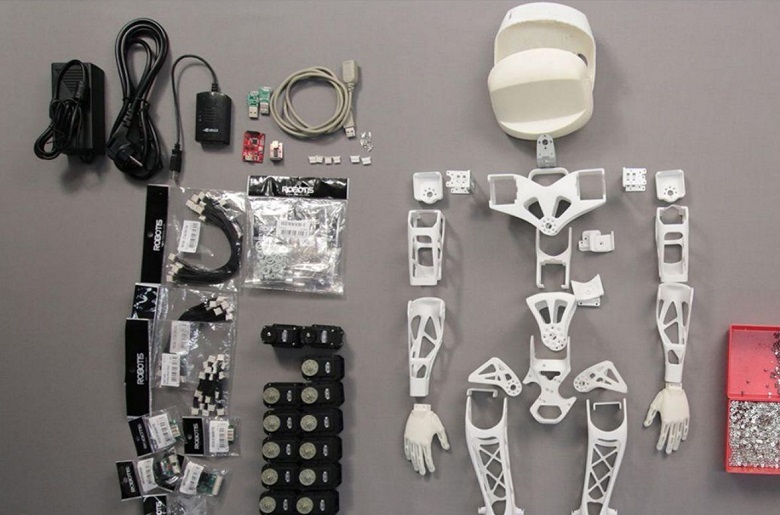

GENERATION ROBOTS: On-demand manufacturing to meet customers needs

The most popular robot, Poppy Humanoid, is comprised of 33 different 3D printed components which can be customized per the client’s needs. With an ever-evolving robot like Poppy, Generation Robots needed an on-demand manufacturing solution to meet the personalized needs of customers

HEXADRONE: Functional drones with a fast time-to-market

Hexadrone realized very quickly when designing their drone the necessity for customization, functionality, and fast time-to-market were essential features for the success of their drones. Sculpteo was the partner that helped Hexadrone meet their challenges.

CONSCIENCE ROBOTICS: Innovative robots powered by Artificial Intelligence

Thanks to 3D printing's potential for innovation, flexibility & speed, French company Conscience Robotics has developed unique intelligent robots, such as the Bering robot, enabling them to move autonomously and in an optimized way.

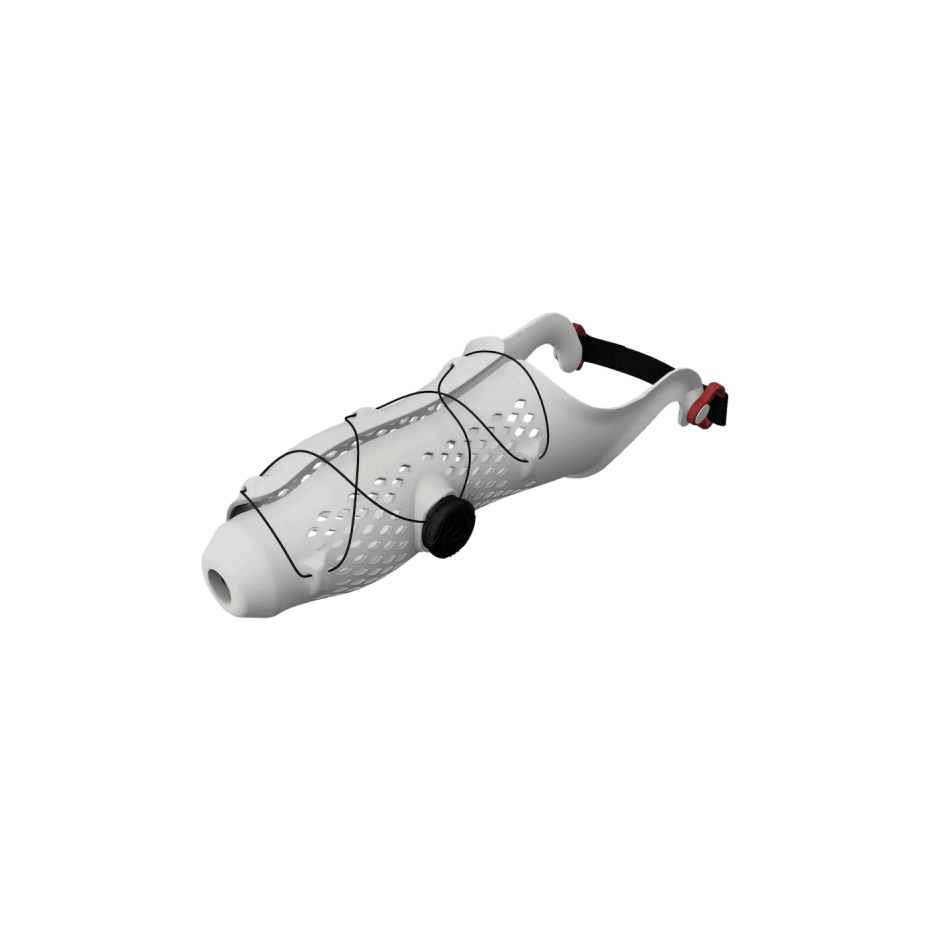

WE ROBOTICS: Creating cargo drones with professional quality

The cargo drone project aims to provide a low-cost add-on module for consumer drones for cargo transport purposes. With minimal time investment and a professional quality and surface finish, WeRobotics could meet all of its manufacturing requirements and still be cost-effective thanks to Sculpteo.

ARTHA: Helping the visually impaired better perceive their environment

French start-up Artha is changing the way visually impaired people can perceive their environment, thanks to an innovative lumbar belt sensitive concept.

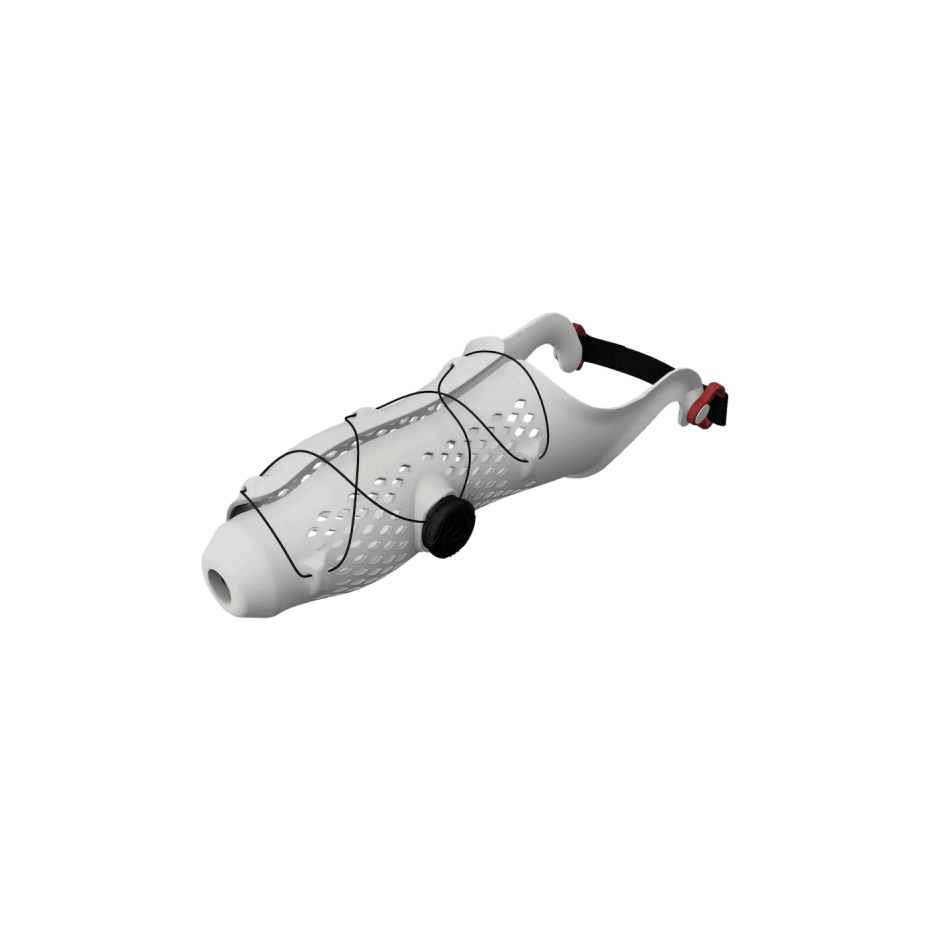

Macu4: Additive Manufacturing helps with designing, iteration and the production of a successful arm prosthesis, The Explorer!

Macu4 turns to the innovative potential of AM to create arm prostheses that are affordable, lightweight, and versatile.

Unlocking the Mysteries of the Brain with an Adaptable Headset

A French research institute was looking for a way to optimize their process to create the best headset possible for their research – which implies finding the adapted prototyping technique, as well as the best material for this usage. Particular attention was also paid to the design of these headsets, with a specific lattice model created with Ultrasim® 3D Lattice Engine from Forward AM.

Daniel Robert Orthopedics uses 3D printing to create unique eco-responsible orthopedic devices.

Daniel Robert Orthopedics explored 3D printing to offer a unique and custom device that allows for comfort, breathability and is lightweight, while still maintaining flexibility in manufacturing and design.

Schlather uses 3D printing to create customized medical aids

The integration of 3D construction has opened up completely new possibilities for the production of orthopedic aids for Schlather GmbH. With 3D printing and PP material, Schlather developed a Dynamic Foot Orthosis (DFO) to correct various deformities such as a clubfoot or extremely high arches.

GENERATION ROBOTS: On-demand manufacturing to meet customers needs

The most popular robot, Poppy Humanoid, is comprised of 33 different 3D printed components which can be customized per the client’s needs. With an ever-evolving robot like Poppy, Generation Robots needed an on-demand manufacturing solution to meet the personalized needs of customers

HEXADRONE: Functional drones with a fast time-to-market

Hexadrone realized very quickly when designing their drone the necessity for customization, functionality, and fast time-to-market were essential features for the success of their drones. Sculpteo was the partner that helped Hexadrone meet their challenges.

CONSCIENCE ROBOTICS: Innovative robots powered by Artificial Intelligence

Thanks to 3D printing's potential for innovation, flexibility & speed, French company Conscience Robotics has developed unique intelligent robots, such as the Bering robot, enabling them to move autonomously and in an optimized way.

WE ROBOTICS: Creating cargo drones with professional quality

The cargo drone project aims to provide a low-cost add-on module for consumer drones for cargo transport purposes. With minimal time investment and a professional quality and surface finish, WeRobotics could meet all of its manufacturing requirements and still be cost-effective thanks to Sculpteo.

GIRBAU: Freedom of design to improve their machines performances

Girbau turned to 3D printing for the speed, efficiency, limitless design possibilities, and cost-effectiveness of this technology to create the single solution part they needed to optimize their folding machines.

Lunaar is using 3D Printing to customize Augmented Reality headsets!

Augmented collaboration experts Lunaar have developed an adaptable clip solution to fit Personal Protective Equipment helmets and bring Augmented Reality to workers, enabling various industries around the world to enter the digital age.

KOOVEA: Developing reliable sensors

Koovea explored 3D printing to enter the market with high-quality products and technologies. Koovea developed their temperature sensors through an intense iteration process to create a reliable solution for their products.

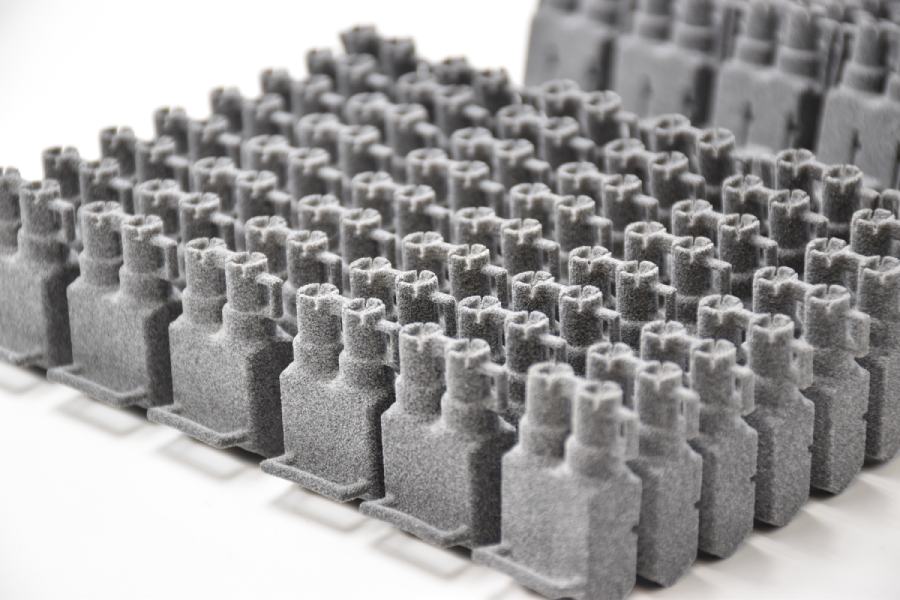

BERNAY AUTOMATION: Streamlines its production process quickly and efficiently using AM

To mass-customize their vibrating bowls in a quick and cost-effective way, Bernay Automation turned to the innovative power of 3D printing and Sculpteo’s reliable online manufacturing services. By adopting additive manufacturing technology into its production process the company was also able to streamline and create a sustainable production process while still maintaining a competitive edge.

UWTI: From small series to production in a short time

Producing this game was a new challenge for Arnaud and Arnaud, going from prototyping to small series production in a short time. With 3D printing, Arnaud and Arnaud were able to adapt production to market demand, to reduce inventory and production overruns.

OVERLINE SYSTEM: Adaptable headphones to meet customers needs

Overline Systems turned to 3D printing technology to create a frame for their headphones that could easily be changed to address market trends and customer needs. They also needed a fast turnaround time to get their headphones into the market, with economic iterations to final parts.

Do you want to write your own success story?

Try out Sculpteo's online 3D printing service today!

There is no minimum order quantity when you use Sculpteo, an online printing service company; from a single object to 10 000+ parts, you can 3D print the exact amount of parts you need. This is why additive manufacturing is particularly adapted to the creation of limited editions.

With +10 years of expertise in additive manufacturing for production and prototyping, Sculpteo also offers rigorous quality control. With our online 3D printing service, you get professional 3D printing at your fingertips. Create a free account, upload your 3D files, select your material, technology, and post-processing options, and order online.

We’ll take care of the rest in our industrial ISO 9001 factory.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook