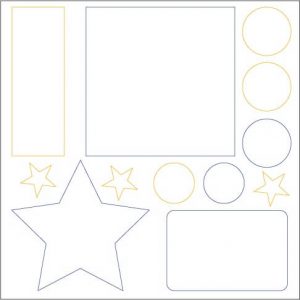

We offer two types of laser engraving:

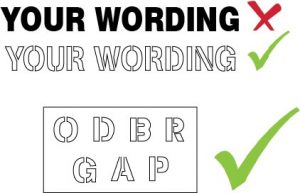

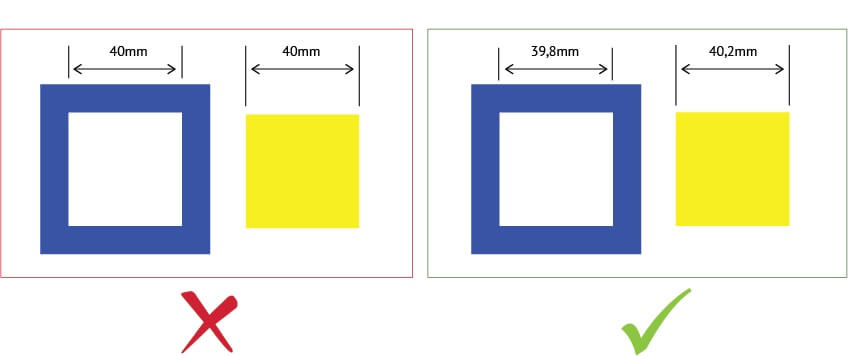

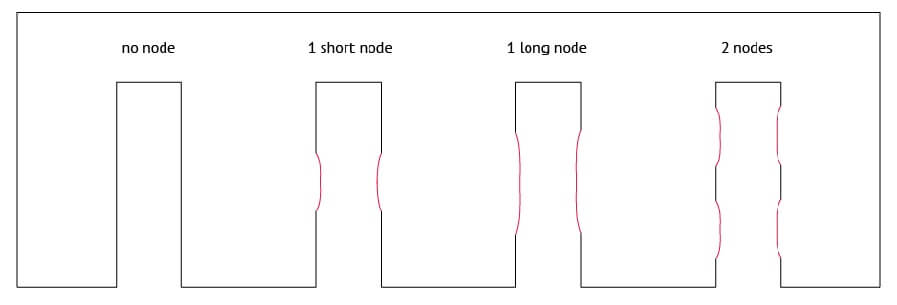

- Line engraving: ideal to engrave a contour. It’s the same operation as cutting, with less power. For this type of engraving, use our cutting tips when designing your file. On our website, only one line engraving level is available.

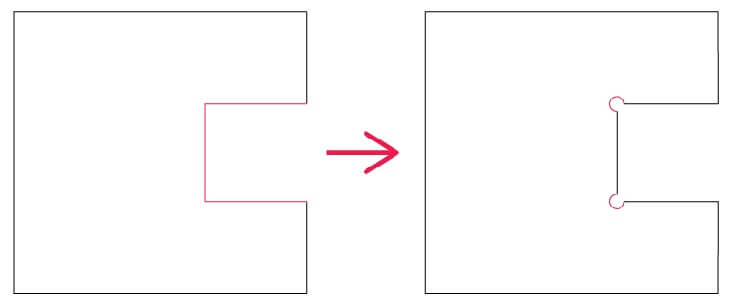

- Surface engraving (also known as infill engraving): For this type of engraving, the outline of your design must absolutely be closed. We offer two levels of surface engraving depth: superficial or deep. With the superficial level, the cut can barely be felt by touch, whereas it is noticeable at a deep level.

Make sure you incorporate different colors in your vector design, according to whether you want a cut, an engraving line or a surface engraving.

POM is a white shiny surface material and is not very suitable for surface engraving. Our Light Surface Engraving gives rather good results (even if it is not quite visible, it adds texture on your surface material). In contrast, Deep Surface Engraving tends to overflow the desired design so we do not recommend to use this technique on POM material.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook