| Maximum size | 180 x 110 x 290 (z) mm |

With CLIP (DLS), parts are limited by the area of the build platform and the height the platform can travel to. If you need to build something larger, you’ll have to print your design in several parts and assemble it later. Check out our tips regarding Minimum Clearance and Spacing.

Tips

Use wall angles above 40 degrees: Wall angles above 40 degrees don’t need to be supported. Printing self-supporting parts is faster and uses less resin thus shorter lead time for delivery. It also eliminates the step of removing the supports.

Tips

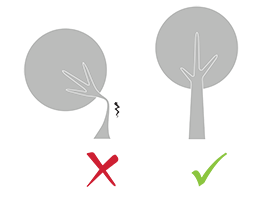

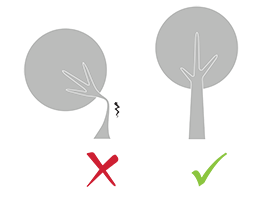

Avoid sharp angles, use curved corners: Gradually curving forms, are well-suited to CLIP printing. If your starting design has sharp angles, try to smooth the design. You can add fillets, bars, and ribs to support and smooth 90° angles.

Do not forget

Keep in mind that our solidity check tool does not detect physical aberrations such as floating parts, unstable position, parts supporting too much weight relative to their thickness, etc. Particular care must be given to the geometry of your design and the most stressed parts must be thickened.

| Minimum wall thickness | Unsupported: 2.5 mm

Supported: 1 mm |

Recommended thickness for certain structural features will vary based on their specific nature. For example, a vertical wall 5 cm in height will be somewhat flexible if it is printed at a thickness of 1 mm, but rigid if it is printed at a thickness of 1.5 mm.

The walls of your object must be thick enough to support the weight of the object without breaking under its own weight. We recommend designing your model with the material’s minimum design standards located in “Tips & Tricks.” This resolution holds true for short walls on the order of 2mm protruding perpendicular to the build direction (XZ and YZ planes) as well as in the XY plane. As it is the case with any thin or small feature, anything with a high aspect ratio (long and thin) will be fragile and need to be supported by other design features (ribs or fillets) or removable support structures. When designing thin/small features, keep aspect ratio 1:4 to minimize distortion. For the upper limit, try to design your walls no thicker than 1cm as bubbles may develop.

Moreover, tall and large parts have a tendency to warp and must be supported to maintain rigidity throughout the printing process. Warping can be caused by heat, vacuum forces, and thin walls. For larger parts, 0.5mm may not be enough to avoid warping depending on the cross sections.

Tip

Make walls thicker than 1 mm: Walls thinner than 1 mm are difficult to print and are best avoided. It is possible to add a support structure to maintain stability. For example, if you are modeling a bust of a person, you can attach thin aspects of the design like the ears in more places around the model’s head. Doing that will avoid cantilevered and easily breakable elements in the final print.

With a 0.8 wall thickness, your design will be slightly flexible. To obtain more rigidity, we advise a 2mm wall thickness.

Tip

Make walls and solid blocks of resin thinner than 10 mm: As parts thicker than 10 mm may suffer from heat-related distortion and bubble formation, try to avoid printing block-like models. However, by hollowing out solid areas and adding supporting 3D lattices, you can convert blocky designs into ones more suitable for CLIP (DLS) printing.

Tip

Keep cross-sections below 50 mm: We are able to design models as small as 1 cm3 as small parts are light and therefore resistant to being deformed by gravity. We can print parts longer than 50 mm in the z-axis, but we try to avoid designs with cross-sections larger than 50 mm because they may distort during printing.

| Minimum size of details | 0.5 mm |

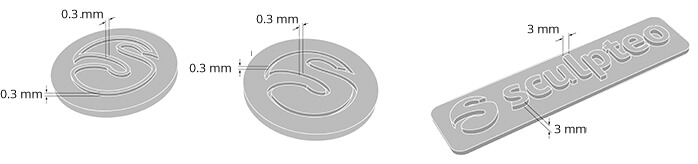

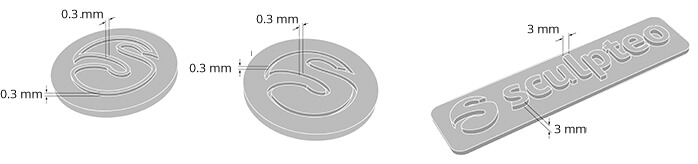

| Minimum height and width details | Embossed: 0.3 mm

Engraved: 0.3 mm |

| Minimum height and width for a readable text | 3 mm |

| Enlargement ratio | 1/1 |

A detail’s minimum precision is mainly determined by the resolution of our printers. However, during the cleaning process, a fine layer of detail can also be lost. In order for a detail and text to be visible we recommend following our recommended sizes at the very least. It is possible to go to a minimum etching and embossing detail of 0.1 mm but visibility will decrease. To ensure details will be visible, their width should be at least as big as their depth.

The smallest resolvable text is 8 points (which equals to 11 pixels or 3 mm), in both recessed and protruding features. In some instances, especially in the XY plane, font sizes smaller than 8 points may be possible but run the risk of losing detail due to over-curing, the unintended resin of curing across a feature.

| Assembly? | Yes |

| Minimum space | 0.4 mm |

Objects printed in polyamide can be printed to be assembled. As long as a width of at least 0.4 mm is left between the different parts of the object.

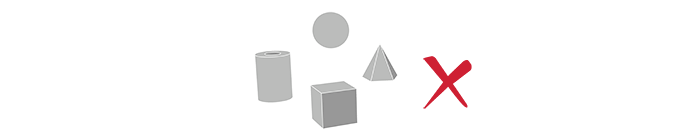

| Files with Multiple Objects ? | No |

It is not possible to upload a file to be printed in resin with multiple objects.

It is not possible to print a 3D file containing several objects, that’s why we cannot accept files that contain clusters of multiple objects . However, don’t worry, this doesn’t mean you’ll pay more for your multiple objects: to reduce the 3D printing cost, we set up a different price calculation as soon as you order two or more objects with CLIP (DLS).

You can also use our online tools and see our tricks and tips on how to reduce your 3D printing price.

To get more information on our additive manufacturing service, you can contact our qualified sales team.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook