Which 3D printing resin should you choose for your project?

Posted By Lucie Gaget on Aug 8, 2018 | 0 comments

When starting a new 3D printing project, you necessarily have to choose your 3D printing material carefully. Indeed, the mechanical properties of your material will have to fully match the needs of your project. As you may know, choosing the right material is a decisive step and you can’t neglect it.

We recently helped you to choose the best plastic and metal 3D printing material, and today, we are going to focus on resin 3D printing. Which 3D printing resin will be the best for your project? At Sculpteo, we are offering various resins, but it can be difficult for you to make your choice.

Do you need to use 3D printing to make prototypes, mechanical parts, or ornamental objects? In this blog post, we are going to help you find the best resin material for your project.

3D printing resin: How does it work?

At Sculpteo, we are offering various resin materials. We are offering two different technologies to print your resin projects. Let’s take a closer look at these 3D printing processes.

The CLIP (or DLS) technology

CLIP stands for Continuous Liquid Interface Solution (or DLS for Digital Light Synthesis). This technology is a photochemical process using digital light projection. It is working by projecting light through an oxygen-permeable window into a reservoir of liquid resin, curable with UV light. A sequence of UV images is projected to solidify the parts, as the build platform is rising. It will shape the part according to your 3D design. This technique allows to work with strong, flexible or transparent resins and will help you to get really detailed parts.

This additive manufacturing technology has been developed by Carbon. Using our online 3D printing service, you can 3D print your resin parts with these following materials: Prototyping Acrylate, Elastomeric Polyurethane, Flexible Polyurethane, Rigid Polyurethane 70, Urethane Methacrylate. The resin 3D printer that we are using for these materials is the M1 by Carbon.

The Polyjet technology

The Polyjet technology prints photopolymer resins. This 3D printing process works similarly to inkjet printing, but instead of jetting drops of ink onto paper, the 3D printer jets layers of curable photopolymer liquid onto the build tray. During the printing, the Polyjet printer jets and instantly UV-cures tiny droplets of liquid photopolymer.

This layer by layer technique creates the object you need, following the shape of your CAD file. After the photopolymerization is completed, the batch is then placed under a pressurized water jet. This step allows to remove the liquid excess or the supports quite easily.

While using our online 3D printing service, you will be able to print VeroWhite or VeroClear resin using the polyjet technology.

Resin materials: Which one is the best for your project?

There is a wide range of resins available on the market. Each one has its technical specifications. Let’s see what resin material you could choose for you project, using our online 3D printing service.

-

Prototyping Acrylate

Prototyping Acrylate is using the CLIP (DLS) technology to manufacture resin parts.

Prototyping using resin 3D printing is not the most cost-effective method. But some projects could require the use of this material during their development process. For them, prototyping acrylate could be a solution.

This printing material is allowing to get detailed objects. Moreover, the printed part will have a smooth and shiny surface, but a moderate strength. Prototyping acrylate will be more adapted for ornamental projects, proof of concept and rapid prototyping.

You can choose different finishes with this material: You can get a raw or polished part, in black, grey, or white!

-

Urethane Methacrylate (UMA 90)

Among the cheapest resins available on our online 3D printing service, you will also have the opportunity to try our Urethane Methacrylate (UMA 90). We recently added this amazing resin material to our catalog, in order to offer you new possibilities for your projects!

This UMA material is one of the strongest resins that we are now offering. It is an interesting material as a lot of its mechanical properties are similar to one of the most traditional plastics used in the 3D printing industry: Nylon PA12.

This resin can create functional and finished parts, but it is also quite interesting for prototyping. Indeed, Urethane Methacrylate is a great method to prototype impellers and hollowed parts for fluid circuits.This material doesn’t require a polishing process, it will reduce the costs and allows you to print a part that will have a good surface. Thanks to UMA, you can make some precise tests with your prototypes. This resin will be a great asset for your product development!

You can get UMA parts in black or white. This material is printed using the CLIP technology developed by Carbon.

-

Elastomeric Polyurethane

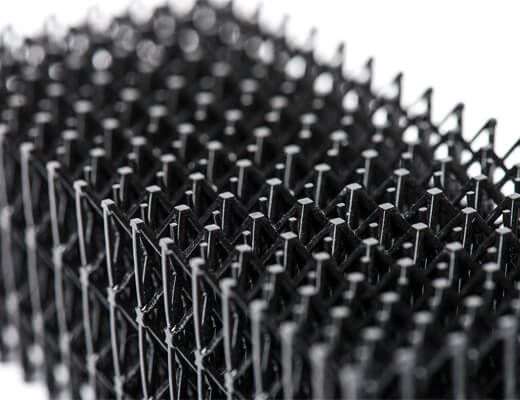

If you need a material with high elasticity, impact and tear resistance, to create projects such as cushioning, gaskets, vibration isolation or seals, this resin is a perfect choice!

Elastomeric Polyurethane or EPU is a high-performance polyurethane elastomer. Indeed, it has an excellent elastic behavior, under a compressive load and cyclic tensile pressure. This resistant resin will allow you to create really good end-used parts, using the CLIP technology.

This resin material is only available in black.

-

Flexible Polyurethane

Here is another resin printed using the CLIP (DLS) technology developed by Carbon. This material is not as elastic as the Elastomeric Polyurethane resin, indeed, the Flexible Polyurethane is a semi-rigid material.

If you are looking for a versatile resin material, specially made for application requiring toughness and an ability to resist to repetitive stresses such as hinging mechanisms and friction fits, try this Flexible Polyurethane resin right now.

Indeed, EPU is offering a high impact strength, which could be perfect to 3D print enclosures.

This resin material is only available in black.

-

Rigid Polyurethane 70

Using our online 3D printing service, you will have the opportunity to try out the Rigid Polyurethane resin, another resin developed by Carbon, and printed with the CLIP (DLS) technology. This resin can allow you to get really detailed parts, comparable to parts manufactured using injection molded plastic.

The particularity of this resin is that it is a really stiff and strong material. If you need to manufacture resistant mechanical parts, this Rigid Polyurethane will definitely fit your expectations. Indeed, it is also a heat-resistant and abrasion-resistant material, which makes it a good solution to 3D print mechanical parts.

This RPU70 is certified by the UL 94 HB flammability classification for a more secured use. You can only 3D print with this material in black.

-

VeroWhite Resin

Are you looking for a colorful 3D printing resin option? The VeroWhite resin could be the good option for you. This opaque polyjet resin is available in a lot of different colors. Originally, the parts are printed in white, but on our online 3D printing service, we are offering to tint the parts.

The surface of the parts printed with the VeroWhite resin is smooth and opaque. It can be used to manufacture medical parts such as surgical guides, or great prototypes.

This resin is printed using the PolyJet technology.

-

VeroClear Resin

The VeroClear resin is really interesting as it is a translucent material. Our VeroClear resin 3D prints are originally translucent. Sculpteo can then tint the object to a color of your choosing. It’s a good solution if you need a resin material to manufacture consumer products for example.

The final 3D printed resin part has a naturally smooth surface, but you can also choose the polished version, which can allow you to get a near full transparency.

We hope that this blog post helped you to find the perfect resin material for your future 3D printed resin parts. As you can see, from rapid prototyping to production, resin can be the good material for a lot of projects. Plus, there is a wide variety of resin materials. Biocompatible resins can be used for the medical sector, and strong resins can be used for mechanical projects.

Do you have a project in mind? Don’t hesitate to upload your 3D models on our online 3D printing service. You will have the possibility to choose the best resin material to manufacture your 3D printed objects.

If you need more tips about 3D printing materials and 3D printing technologies, we recommend you to subscribe to our newsletter. We will share with you all of our advice.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook