Home » 3D Printing Materials » CLIP Resin Material for 3D Printing: 3D printing resin for CLIP technology » Elastomeric Polyurethane

Elastomeric Polyurethane 3D printing material

Elastomeric Polyurethane can be used for both ornamental or mechanical projects. Here are all information, tricks, know-how, and advice to help you print your 3D model in our Elastomeric Polyurethane resin material.

Elastomeric Polyurethane Material Guide

What is Elastomeric Polyurethane?

Elastomeric Polyurethane, or EPU, is a high-performance polyurethane elastomer. It exhibits excellent elastic behavior under cyclic tensile and compressive loads. EPU is useful for demanding applications where high elasticity, impact, and tear resistance are needed such as cushioning, gaskets, and seals.

What can we do with Elastomeric Polyurethane?

With the CLIP (DLS) Process, we’re able to deliver prototypes and end-use products ranging from very small parts that meet tolerance demands to medium parts with precise patterns. CLIP (DLS) enables product designers and engineers to produce polymeric parts that have the resolution, surface finish and mechanical properties required for both functional prototyping and production parts for industries as varied as automotive, medical and consumer electronics.

CLIP (DLS) leverages a range of materials which were designed to meet common engineering requirements — from the elongation and resilience expected of an injection molded polyurethane elastomer to the temperature resistance of a glass-filled Nylon, and much more. The Elastomeric Polyurethane is a rubbery, stretchable material that exhibits elastic behavior through a wide range of temperatures. This material is perfect for the use in gaskets, grommets, and flexible watertight seals.

Resin 3D prints create objects which are particularly smooth and precise. They are perfect for ornamental objects, but they can also be used for more mechanical uses if the strain on the object is not too great. The resin is also often used by large companies when prototyping new designs and can also be used for creating end products. Though everyone from beginning designers to experienced professionals can also benefit from the great liberty in design the material offers.

Pricing

The printing price of your design is calculated automatically the moment it is placed online. As you modify your object you will note that the price changes automatically. The pricing is based on a series of factors, including the volume of material used, the size of the object, and multiple other factors. To see your price in just a few clicks you just need to upload your file.

We estimate our resin prints will be shipped in 6 business days after the order is placed. An additional day or two may also be required depending on the finishing options you choose.

3D printing process of Elastomeric Polyurethane

With CLIP (DLS) technology, the 3D print is grown continuously without stopping from the vat of resin. A continuous sequence of UV projected images, similar to a digital video, is projected as the object is drawn out. The result is a part that is smooth on the outside and solid on the inside, with predictable mechanical properties that much more closely resemble injection-molded parts.

What are the finishing options available for Elastomeric Polyurethane?

We remove the support structures for you during our post-processing steps, but the surfaces where the supports structures come in contact with the part will be visible but can be sanded and finished by a technician upon request. This means there are considerations you should keep in mind during the design of your part to facilitate not only the successful construction of your part but also the removal of support structures and the finishing of your surfaces.

There are multiple finishing options available through Sculpteo:

- Raw: Supports are removed from the model. Support scars/bumps will still be visible.

- Polished: Supports and support scars/bumps are removed.

| Standard layer thickness | 100 µm |

Our printer by Carbon3D allows us to print with a layer thickness of 100 µm or 0.1 mm. In consequence, it is important that your prints are exported with the highest quality possible. This will avoid any sort of triangulation during the print – though keep in mind your file cannot be greater than 50mb.

| Maximum size | 180 x 110 x 100mm |

With CLIP (DLS), parts are limited by the area of the build platform and the height the platform can travel to. If you need to build something larger, you’ll have to print your design in several parts and assemble it later. Check out our tips regarding Minimum Clearance and Spacing! While this is the maximum volume possible, certain materials currently have more restrictive envelopes, particularly in the Z axis. If you have a specific need for items with an axis greater than 100 mm (4”) please contact us to review your design with you to help choose the most appropriate material.

| Minimum wall thickness | Unsupported: 2.5mm Supported: 1mm |

Recommended thickness for certain structural features will vary based on their specific nature. For example, a vertical wall 5 cm in height will be somewhat flexible if it is printed at a thickness of 1.0 mm, but sturdier if it is printed at a thickness of >1.0 mm.

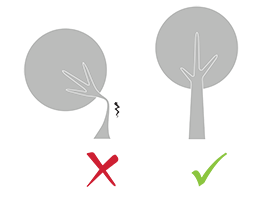

The walls of your object must be thick enough to support the weight of the object without breaking under its own weight. We recommend designing your model with the material’s minimum design standards located in “Tips & Tricks.” This resolution holds true for short walls on the order of 2mm protruding perpendicular to the build direction (XZ and YZ planes) as well as in the XY plane. As it is the case with any thin or small feature, anything with a high aspect ratio (long and thin) will be fragile and need to be supported by other design features (ribs or fillets) or removable support structures. When designing thin/small features, keep the aspect ratio 1:5 to minimize distortion. For the upper limit, try to design your walls no thicker than 1cm as bubbles may develop.

Moreover, tall and large parts have a tendency to warp and must be supported to maintain rigidity throughout the printing process. Warping can be caused by heat, vacuum forces, and thin walls. For larger parts, 1.0 mm may not be enough to avoid warping depending on the cross sections.

| Minimum size of details | 0.6 mm |

| Minimum height and width details | Embossed : 0.3 mm Engraved : 0.3 mm |

| Minimum height and width for a readable text | 3mm |

| Enlargement ratio | 1/1 |

Sculpteo offers an online solidity check tool which highlights parts of the print that may be too thin for a print. From there you are able to tweak your design in order to create an object that is an appropriate thickness. To use it, you just need to upload your 3D file, select your material and click on the “Verification” tab.

Keep in mind that our solidity check tool does not detect physical aberrations such as floating parts, unstable position, part supporting too much weight relative to its thickness, etc. Particular care must be given to the geometry of your design and the most stressed parts must be thickened.

Keep in mind that our solidity check tool does not detect physical aberrations such as floating parts, unstable position, parts supporting too much weight relative to their thickness, etc. Particular care must be given to the geometry of your design and the most stressed parts must be thickened.

Keep in mind that our solidity check tool does not detect physical aberrations such as floating parts, unstable position, parts supporting too much weight relative to their thickness, etc. Particular care must be given to the geometry of your design and the most stressed parts must be thickened.

| Enclosed parts? | No |

| Interlocking parts? | No |

| Minimum spacing between fixed walls | 0.5 mm |

Objects printed in Elastomeric Polyurethane can be printed to be assembled. As long as a width of at least 0.5 mm is left between the different parts of the object.

Clearance should be at least 0.5 mm, however that is the minumum for small objects. Larger objects require more space between their parts. This is due to the SLS printing process. Our printer beds are heated during the process, and larger objects are heated for longer periods. A small space between large objects runs the risk of melting together as it remains under heat for a long period of time. In some other cases, holes should be added to allow us to drain for the excess powder material within the clearance.

| Assembly ? | Yes |

| Minimum space | 0.5 mm |

Objects printed in Elastomeric Polyurethane can be printed to be assembled. As long as a width of at least 0.6 mm is left between the different parts of the object.

| Hollowing ? | No |

| Files with Multiple Objects ? | No |

It is not possible to upload a file to be printed in resin with multiple objects.

It is not possible to print a 3D file containing several objects, that’s why we cannot accept files that contain clusters of multiple objects . However, don’t worry, this doesn’t mean you’ll pay more for your multiple objects: to reduce the 3D printing cost, we set up a different price calculation as soon as you order two or more objects with CLIP (DLS).

You can also use our online tools and see our tricks and tips on how to reduce your 3D printing price.

To get more information on our additive manufacturing service, you can contact our qualified sales team.

Ready to 3D print with Elastomeric Polyurethane?

With Sculpteo’s online 3D printing service you’re just a few clicks away from professional Elastomeric Polyurethane resin 3D printing. Your 3D model is printed with the highest quality and delivered straight to your door.

Get started now!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook