Our actions for more sustainability in 3D printing

As a manufacturer, we understand that it is our responsibility to limit the impact of our activities and to place social and environmental concerns at the center of our business strategy.

Our main actions

In order to improve our environmental and social performance, we focus our efforts on:

Resource-efficient management

Adabptability of our products & innovation

Responsible

sourcing

Optimization of our production processes

Carbon

footprint

Quality of life at the office

Diversity and inclusion

Understand our impact

The first step to solving a problem is to understand it better. This is why we invest time and resources to measure our impacts and implement an improvement strategy based on these measures. At the same time, we have set up a commission for ecology with a panel of volunteer employees from the various Sculpteo departments. This working group aims to identify our areas of progress and develop solutions to achieve these objectives.

What are Sculpteo's commitments?

Additive Manufacturing and sustainability are interconnected. Optimizing the use of raw materials and limiting production waste are the very essence of Additive Manufacturing. It is on these foundations that Sculpteo was built, and our sustainable development policy is based on these values.

1

Reduce waste related to the 3D printing process

2

Consolidate the recycling of raw materials printing and offer a recycling channel for obsolete parts for our customers

3

Improve our use of water resource in the post-treatment stages

4

Switch to consumption

of green energy in our production sites

5

Develop our offers towards more sustainability by offering materials that are recycled or from renewable sources

6

Make our performance reporting accessible, since it forms the foundation for all our decisions

7

Offer tools for measuring the environmental impact of our products to our customers

8

Encourage the adoption of soft mobility as well as digital and energy sobriety in our premises in Villejuif (France) and in our American branch

9

Raise awareness among our employees and give them the means to participate in its improvement

Did you know ?

Additive manufacturing holds great potential in reducing your parts’ ecological footprint. Find out why.

More economical in raw resources

Streamlined and simplified supply and production chains

Design flexibility at the service of eco-design

Avoided sources of pollution

Responsible Resource Management

RE-cycleo: our recycling program for obsolete parts

To promote a circular economy, we offer customers a recycling service for Nylon PA12 and PA11 parts. The recycled material can be used in the plastics industry, giving old parts a second life.

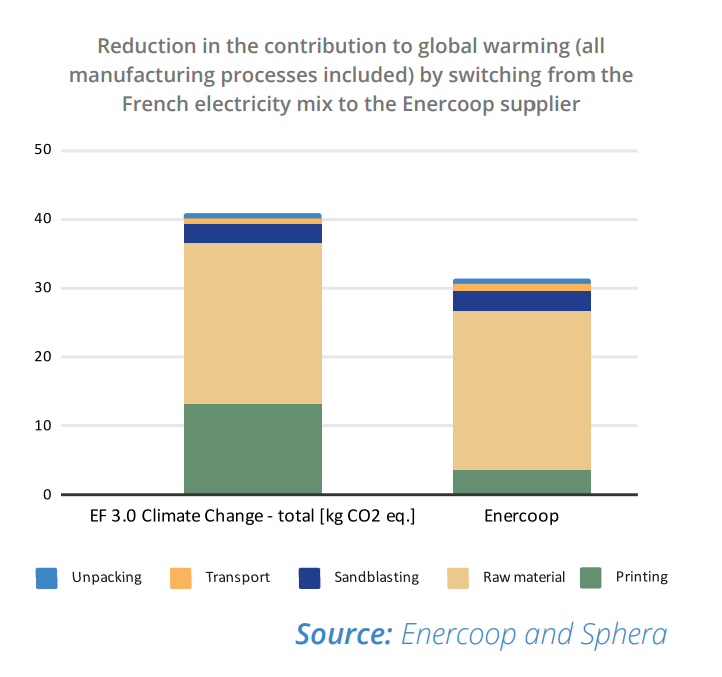

Our workshops are powered by 100% renewable electricity

We are proud to announce that all of our production sites are now fully powered by green energy. This significant transition to renewable energy has a direct and positive impact on the environmental footprint of our products, leading to a 24% reduction in environmental impact for each PA11 MJF job.

Our green electricity suppliers:

A strategy aligned with the UN Sustainable Development Goals (SDGs)

Adopting the SDGs gives us a framework to assess and guide our actions. Our efforts to rationalize our use of materials and energy and encourage the recycling of production waste that cannot be avoided align with SDG 12. By integrating more sustainable alternatives into our range of materials, we support SDG 9. Optimizing our production processes contributes to SDG 8. Our commitment to diversity and inclusion aligns with SDG 5. Our efforts to reduce our carbon footprint are directly linked to SDG 13 on climate action. In sum, every aspect of our work at Sculpteo is driven by the desire to achieve these sustainability goals.

Working together

Sculpteo is a member of the AMGTA association whose objective is to promote the environmental advantages of additive manufacturing compared to traditional manufacturing methods and to raise public awareness of these issues.

“We understand that every choice we make as a business has environmental implications, which is why we constantly strive to improve our environmental performance.”

Alexandre d’Orsetti, CEO @Sculpteo

Through the power of collaboration with our trusted partners, we strive to make a positive impact that will benefit all.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook